A longitudinal pressure divider at the body of electronic accelerator

An electron accelerator and vertical technology, applied in the direction of electrical components, accelerators, etc., can solve problems such as electric field deformity, affecting industrial development, and high energy climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

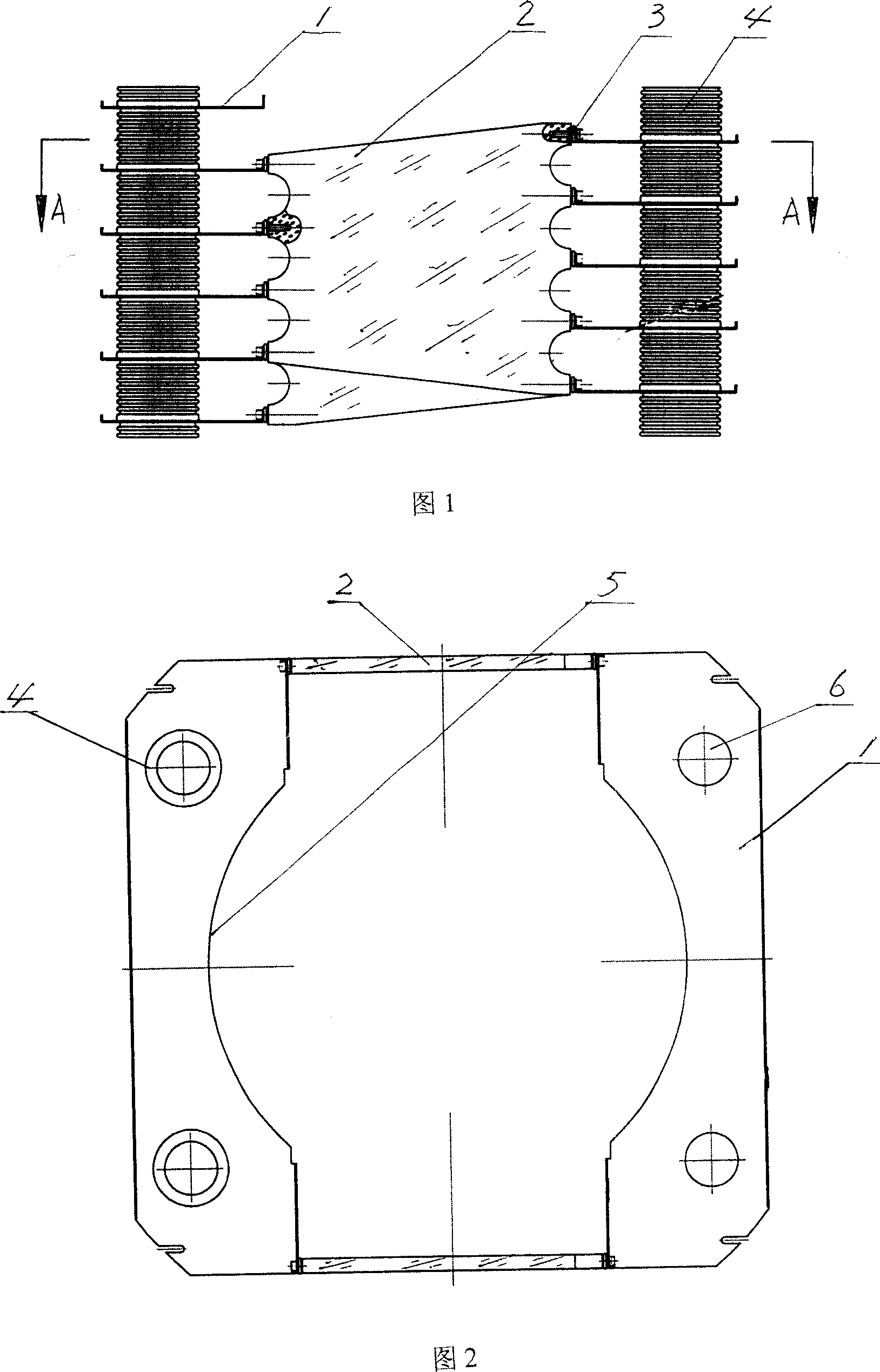

[0011] As shown in Fig. 1 and Fig. 2, the longitudinal voltage dividing device of the main body of the electron accelerator of the present invention contains four insulating pillars 4, and the four insulating pillars are divided into two pairs, each pair of insulating pillars 4 is equipped with a number of pressure dividing sheets 1 . Said pressure dividers 1 are rectangular, they are arranged at equal intervals along the longitudinal direction of the insulating pillars 4, and their two ends are bonded to the corresponding insulating pillars 4, thus forming two units. The pressure dividing sheet 1 in each unit is all processed with arc-shaped missing edge 5 on the same long side, and the pressure dividing sheet 1 side of two units with the arc-shaped missing edge 5 is oppositely arranged, and between the two units Two plexiglass plates 2 are provided, and the two vertical sides of each plexiglass plate 2 are respectively fixedly connected with the corresponding pressure dividi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com