Pressure relief valve device for stirring station powder hopper

A safety valve and mixing station technology, applied in the field of pressure safety valve devices, can solve the problems of deformation of the weak part of the top of the powder silo, the pressure safety valve cannot be opened, and the safety function cannot be achieved, and achieves reduced maintenance, simple structure, Easy anti-corrosion and anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

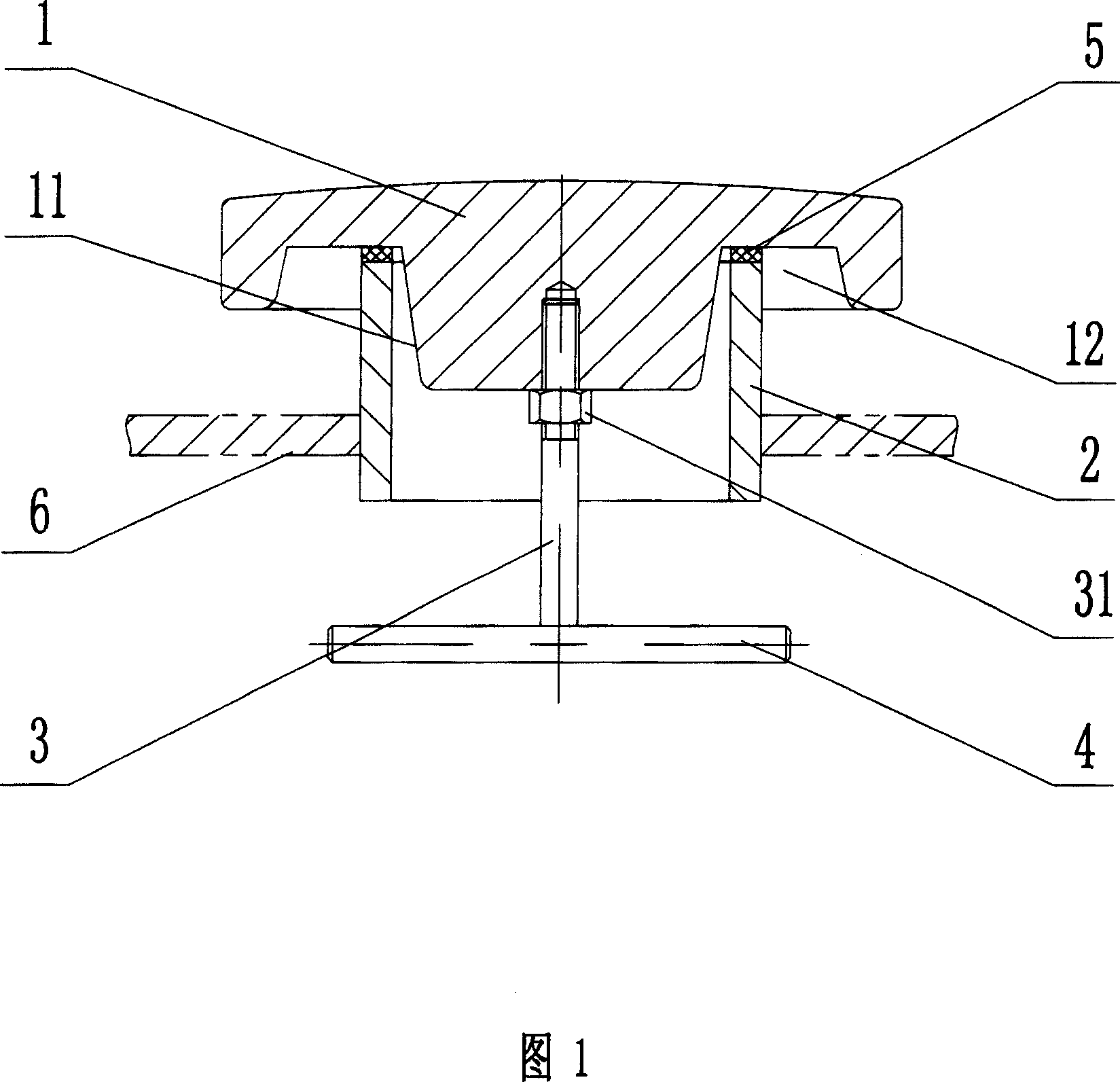

[0016] As shown in Figure 1, the powder silo pressure safety valve device of the mixing station of the present invention is installed on the powder silo body 6 of the mixing station, including a counterweight cover 1, a cylinder body 2, a connecting piece 3 and a limiting piece 4, connected One end of part 3 is threadedly connected with counterweight cover 1, the other end is fixedly connected with limiter 4, cylinder body 2 is fixedly connected with powder material bin body 6, counterweight cover 1 is set above cylinder body 2, and counterweight cover 1 is A groove 12 is provided, the upper part of the cylinder body 2 is placed in the groove 12, the limiting part 4 is arranged under the cylinder body 2, and the connecting part 3 is arranged in the cylinder body 2. The limiter 4 cooperates with the cylinder body 2 to prevent the counterweight cover 1 from flying out when the pressure is released. The counterweight cover 1 is provided with a guide device 11 matched with the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com