Hydrothermal method for preparing superstructure visible light responsive Bi2WO6 photcatalyst

A photocatalyst and superstructure technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large energy consumption, large size, and ineffective regulation problems such as product morphology and structure, to achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

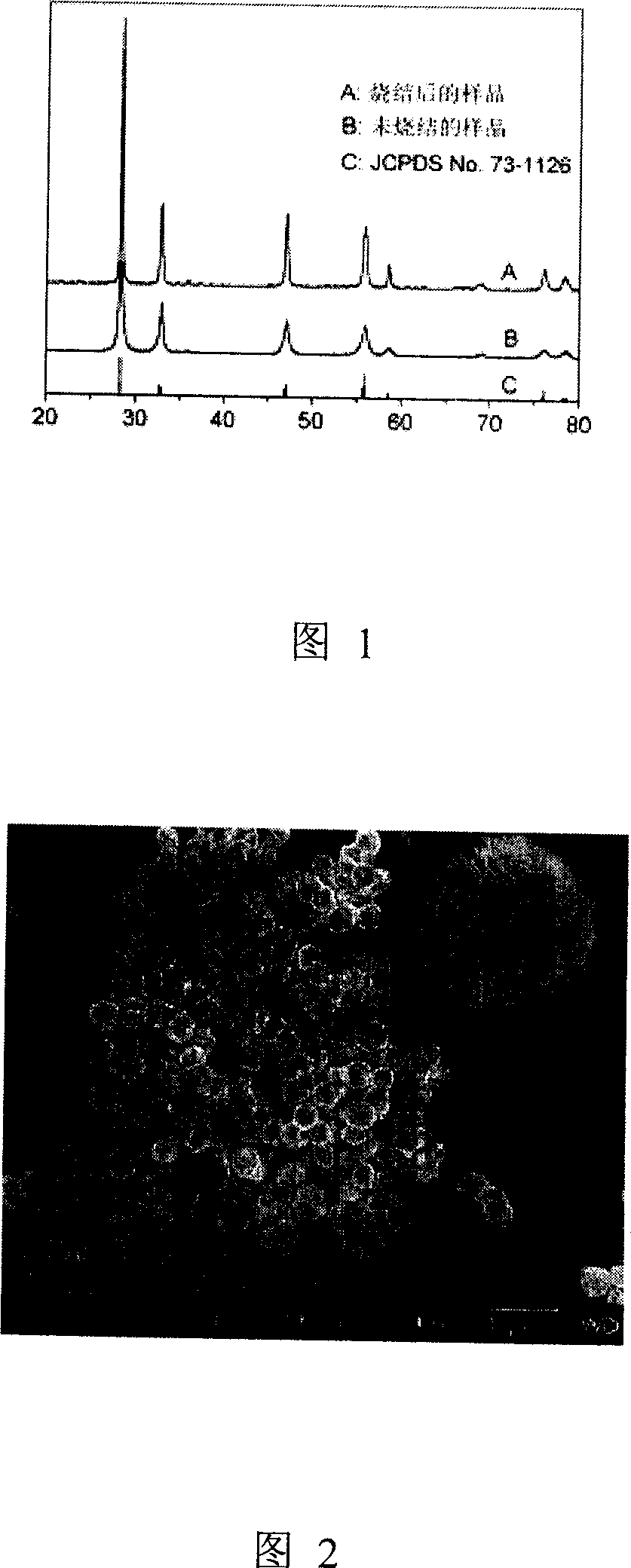

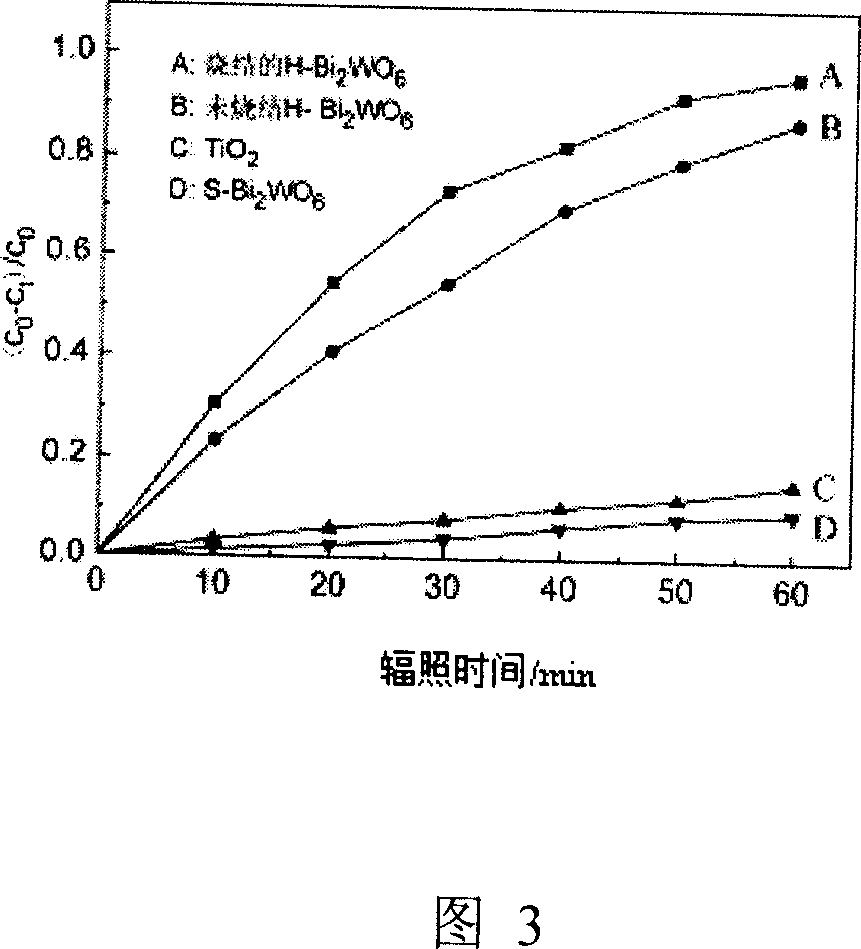

[0018] Bi 2 WO 6 The superstructure precursors were prepared using Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 (Analytical pure) is synthesized as raw material, according to stoichiometric ratio, weighs 0.97g Bi(NO 3 ) 3 ·5H 2 O (analytical grade) was dissolved in 50 mL of water, and then 0.33 g of Na 2 WO 4 (analytical pure), stir to form a white suspension precursor, adjust the pH value to 0.5-2.5. Then pour the white suspended precursor solution into the hydrothermal kettle for hydrothermal treatment. After comparative experiments, the filling capacity of the precursor in the hydrothermal kettle was selected as 80%, the temperature range of the hydrothermal reaction was 160°C, and the hydrothermal reaction time was 20h . After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, and then dried at 80°C. As shown in Figure 1, through the XRD composition, the orthorhombic Bi 2 WO 6 superstructure. A in F...

Embodiment 2

[0022] Bi 2 WO 6 The superstructure precursors were prepared using Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 (Analytical pure) is synthetic as raw material, according to stoichiometric ratio, weighs 2mmol Bi(NO 3 ) 3 ·5H 2 O (analytical grade) was dissolved in 50 mL of water, and then 1 mmol Na 2 WO 4 (Analytical pure), stir to form a white suspension precursor solution, and adjust the pH value to 0.1-5. Then pour the white suspended precursor solution into the hydrothermal kettle for hydrothermal treatment. After comparative experiments, the filling capacity of the precursor in the hydrothermal kettle is selected as 80%, the temperature range of the hydrothermal reaction is 160°C, and the hydrothermal reaction time is 20h . After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, dried at 80°C, and sintered at 550°C. As shown in Figure 1, after XRD composition analysis, the orthorhombic Bi is also obta...

Embodiment 3

[0024] Bi 2 WO 6 Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 (analytical pure) is synthesized as raw material, according to stoichiometric ratio, weighs 2mMol Bi(NO 3 ) 3 ·5H 2 O (analytical grade) was dissolved in 50 mL of water, and then 1 mMol Na was added 2 WO 4 (analytical pure), then add surfactant p123, stir to form a white suspension precursor solution, and adjust the pH value to 0.5-5. Then pour the white suspended precursor solution into the hydrothermal kettle for hydrothermal treatment. The filling capacity of the precursor in the hydrothermal kettle is selected as 60%, the temperature range of the hydrothermal reaction is 160°C, and the hydrothermal reaction time is 20h. After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, and then dried at 80°C. In this example, Bi with a particle size of about 3 μm 2 WO 6 The superstructure is formed by the aggregation of nanorods with a length of 20nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com