Engine cam shaft cover with oil sump

A camshaft cover and engine technology, applied in the lubrication of valve accessories, etc., can solve the problems of increasing the specific pressure bearing strength of the bearing surface, affecting the formation of oil film, increasing the difficulty of the arrangement of the mechanism of the compact engine, etc., achieving good lubrication effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

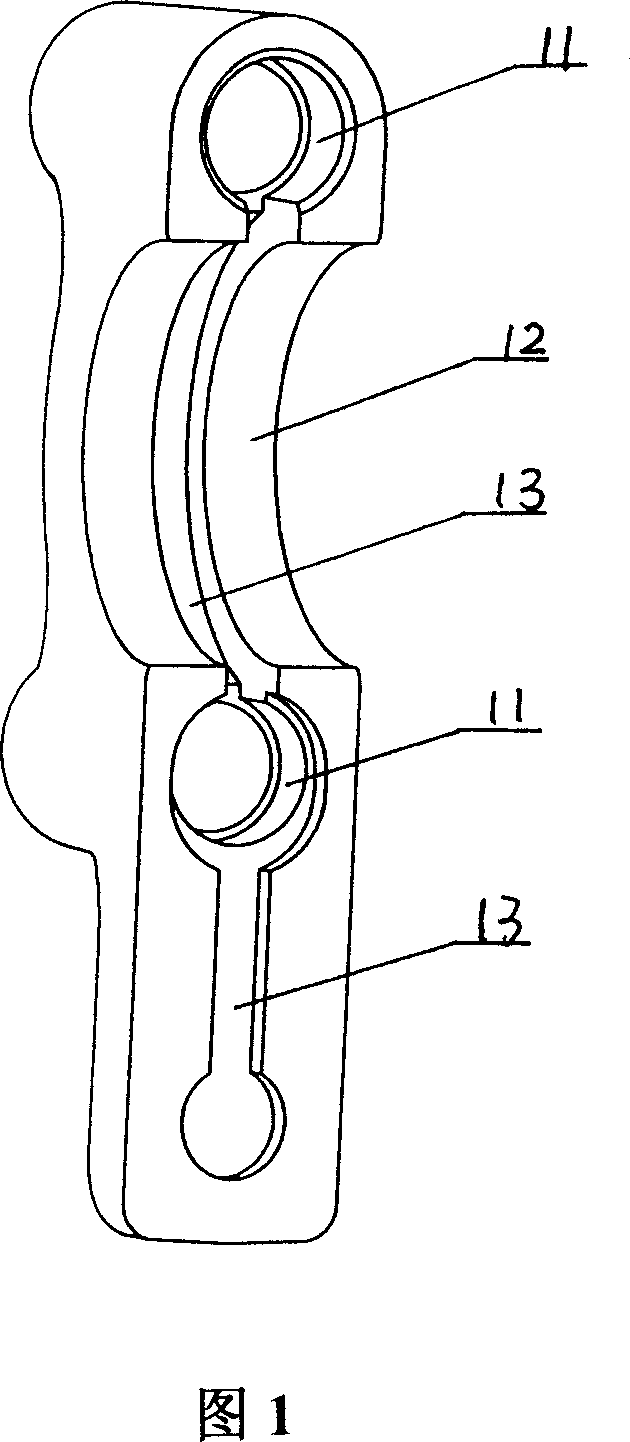

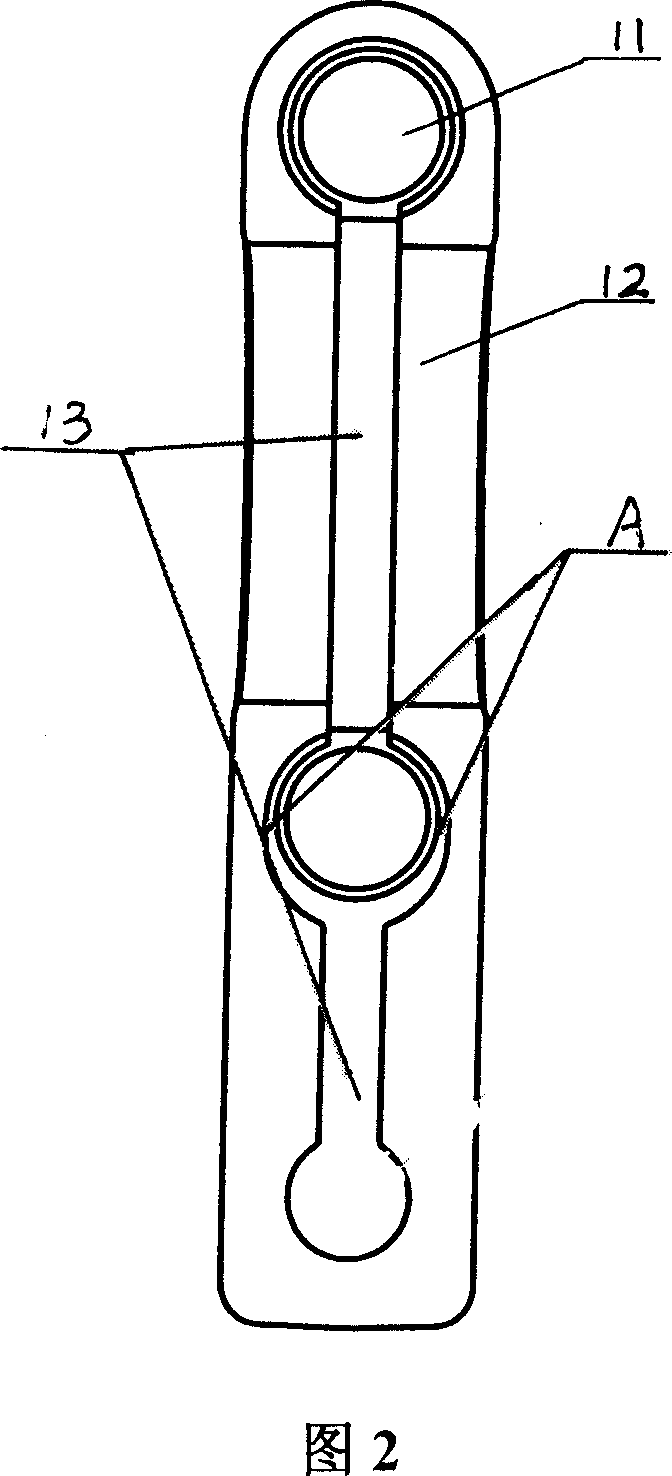

[0012] Referring to Fig. 1 and Fig. 2, the two ends of the camshaft cover are bolt holes 11 fixed to the cylinder head of the engine, and the middle is a curved surface 12 adapted to the camshaft. Oil groove 13 is made on top, in order to access lubricating oil from cylinder head conveniently, one end of camshaft cover is extended, and oil groove 13 just passes the bolt hole 11 of this end along the joint surface from the extended end of camshaft cover, then leads to the other side along joint surface. Bolt holes 11 at one end. In order to ensure the smooth flow of the oil passage, when the oil groove passes through the bolt hole at the extension end, an eccentric structure A is adopted, as shown in Figure 2.

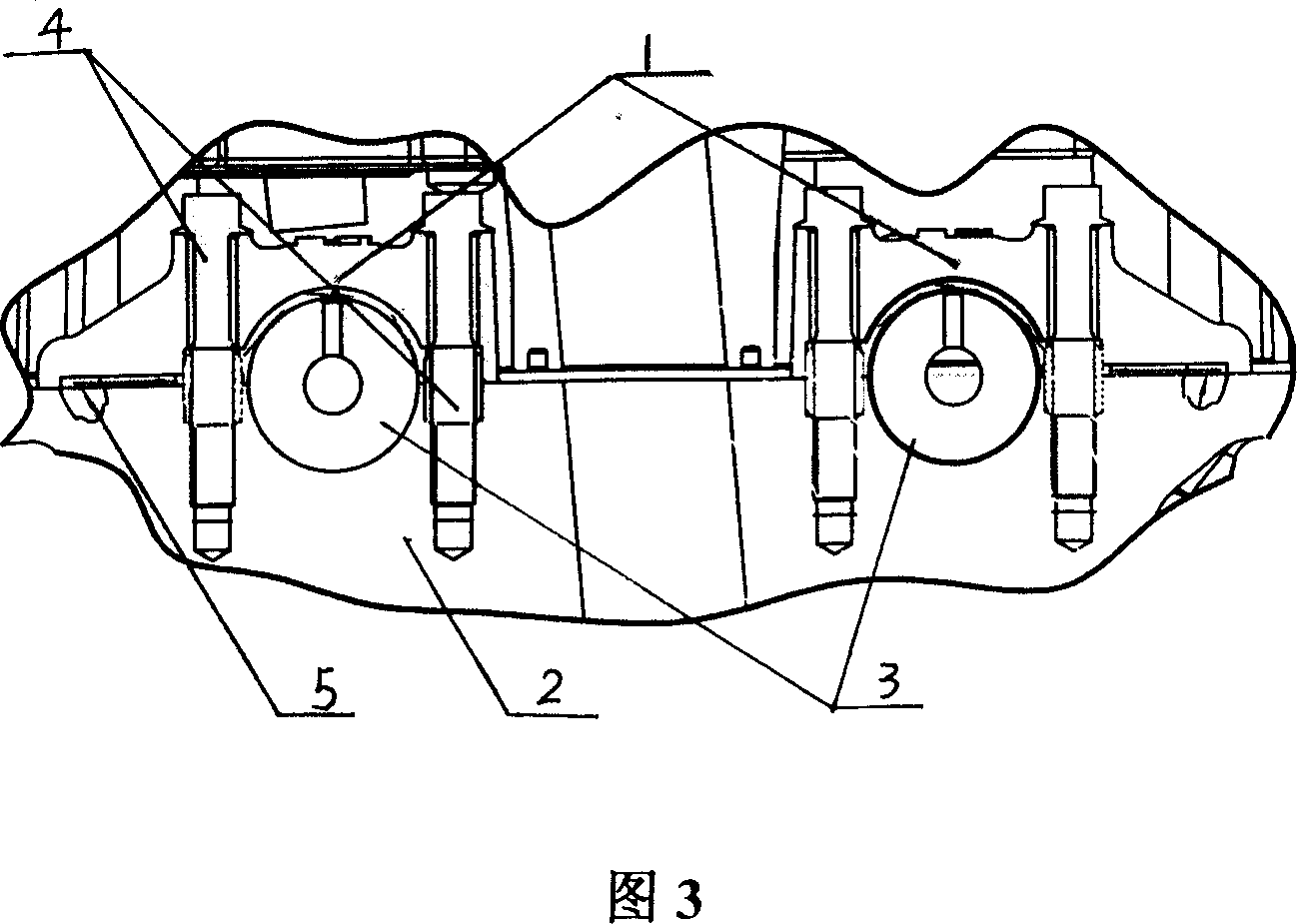

[0013] It can be seen from Figure 3 of the assembly relationship between the camshaft cover 1, the cylinder head 2 and the camshaft 3 that the camshaft cover 1 is fixed to the cylinder head 2 through bolts 4, one on the left and one on the left, and the oil groove 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com