Device for recovering solvent in wind cooling type dry washing machine

The technology of a solvent recovery device and a cooling recovery device is applied in the field of washing machinery, and can solve the problems of large difference in the heat content of the solvent, low thermal efficiency, complex structure, etc., and achieve the effects of convenient and reliable use, reduced operating costs, and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

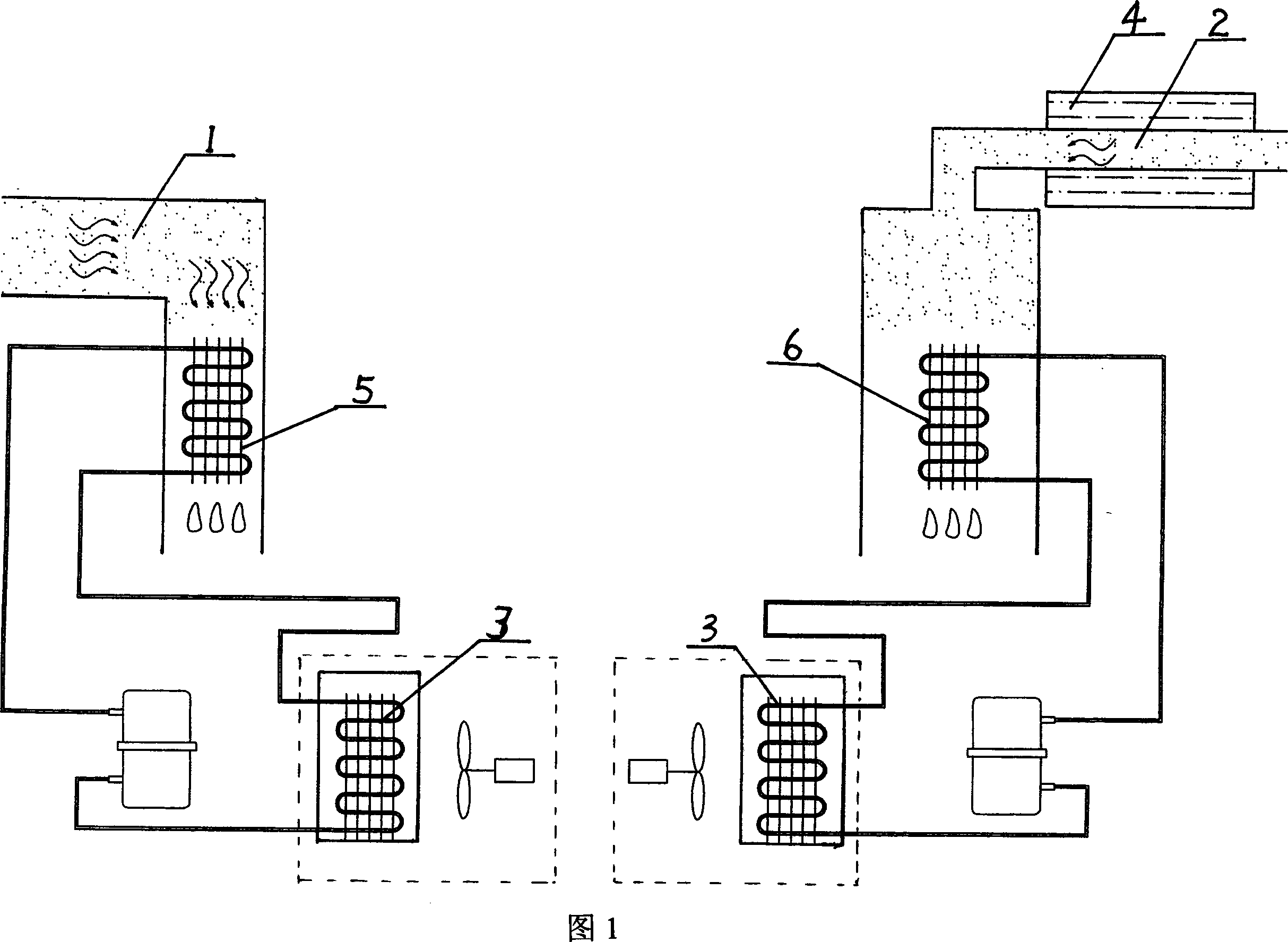

[0020] Embodiment 1, as shown in Figure 1, an air-cooled dry cleaning machine solvent recovery device, wherein the drying channel 1 and the distillation channel 2 are independent of each other, the two channels are respectively provided with a drying solvent cooling recovery device 5 and a distillation solvent Air-cooled heat exchangers 3 are respectively arranged in the circuits of the cooling recovery device 6 and the drying and distillation solvent cooling recovery devices 5 and 6 . When the device in this embodiment is used, since the distillation channel 2 is only communicated with the distillation cooling recovery device 6, the speed and efficiency of distillation cooling recovery solvent can be improved.

Embodiment 2

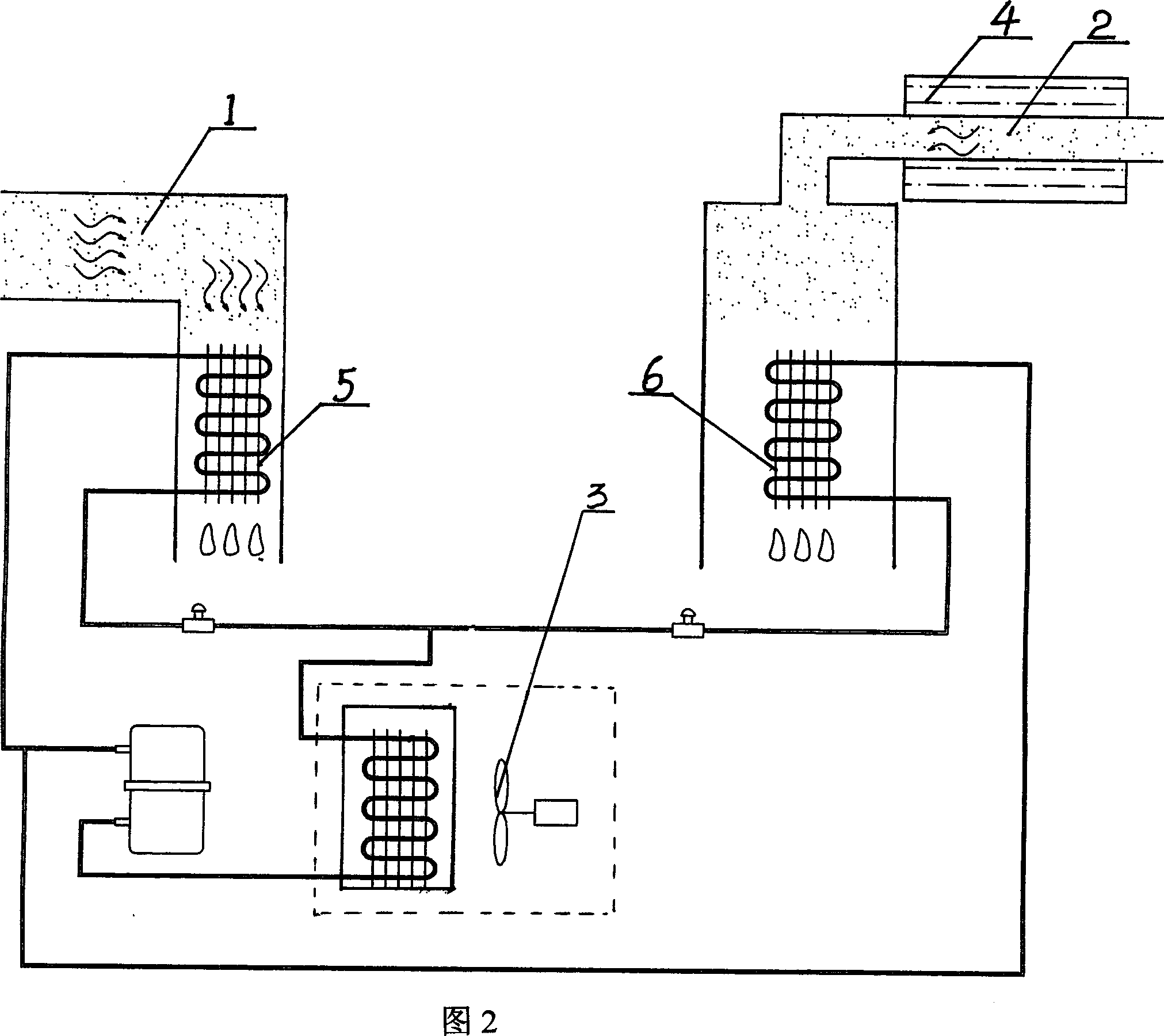

[0021] Embodiment 2, as shown in Figure 2, an air-cooled dry cleaning machine solvent recovery device, wherein the drying channel 1 and the distillation channel 2 are independent of each other, the two channels are respectively provided with a drying solvent cooling recovery device 5 and a distillation solvent An air-cooled heat exchanger 3 is provided after the cooling recovery device 6 and the circuits of the drying and solvent distillation cooling recovery devices 5 and 6 are connected. When the device in this embodiment is in use, because the distillation channel 2 is only communicated with the distillation solvent cooling recovery device 6, the speed and efficiency of the distillation cooling recovery solvent can be improved; The loops are connected to each other and share a set of air-cooled heat exchanger 3, therefore, its structure is more compact than that of Embodiment 1.

Embodiment 3

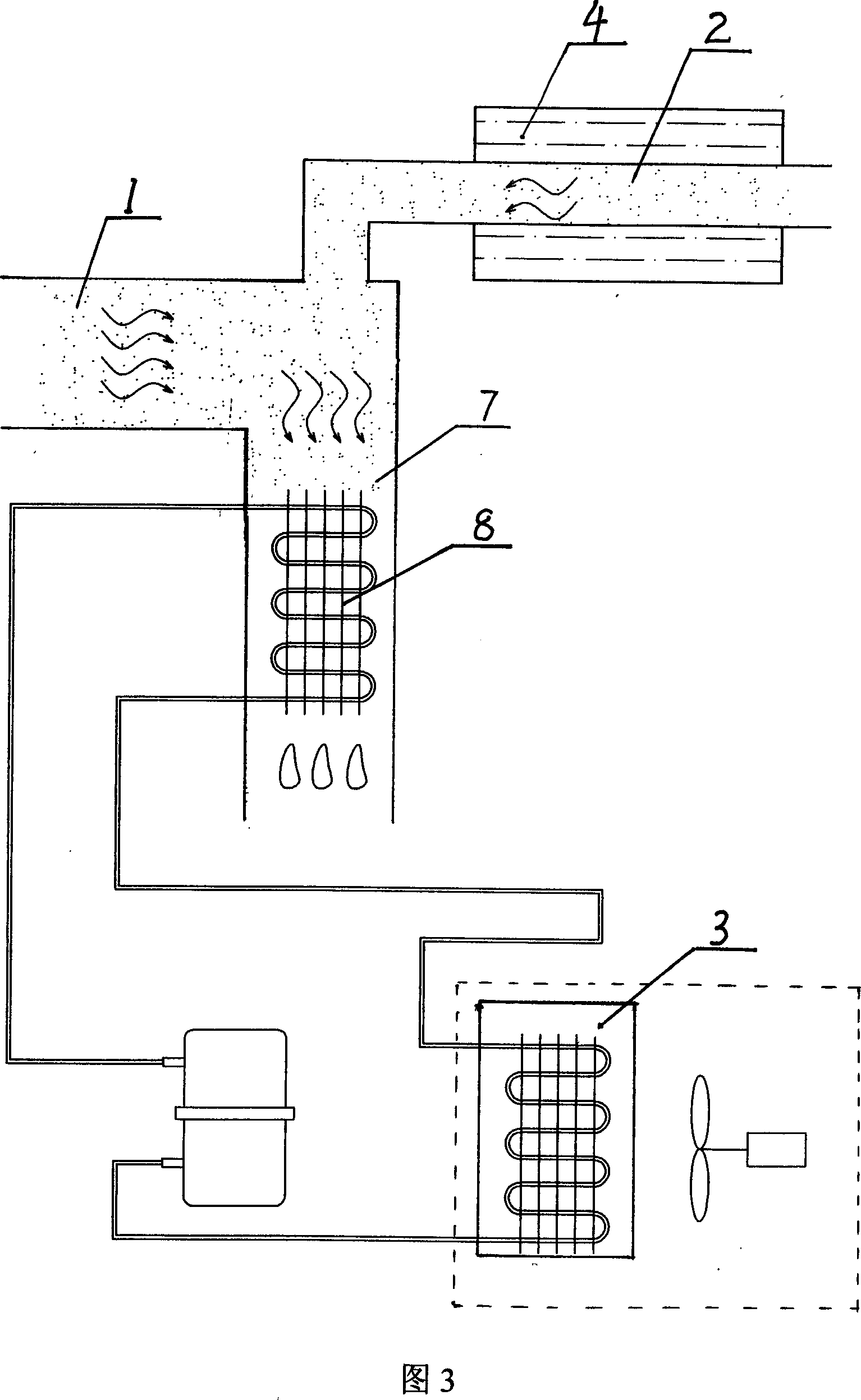

[0022] Embodiment 3, as shown in FIG. 3 , an air-cooled dry cleaning machine solvent recovery device, wherein the drying channel 1 and the distillation channel 2 are respectively connected with the cooling chamber 7, and a set of drying and distillation solvent is arranged in the cooling chamber 7. Cooling recovery device 8, air-cooled heat exchanger 3 is arranged in the circuit of drying distillation solvent cooling recovery device 8. In this embodiment, since the drying passage 1 and the distillation passage 2 communicate with the cooling chamber 7 and its drying and distillation solvent cooling recovery device 8, the structure is the most simple and practical, the solvent recovery efficiency is high, and the operation of the unit has been optimized.

[0023] As shown in Figure 4-6, that is, in Embodiments 4, 5, and 6, the heat exchangers described are all air-cooled heat exchangers 9, and the remaining structures correspond to the above-mentioned Embodiments 1, 2, and 3 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com