Method for removing aluminum trichloride and purifying products in C5 petroleum resin production process

A technology of petroleum resin and aluminum trichloride, which is applied in the field of petrochemical industry, can solve the problems of difficult separation, emulsion formation, and difficulty in obtaining light-colored resins, and achieve the effects of reducing production costs, easy separation, and increasing softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

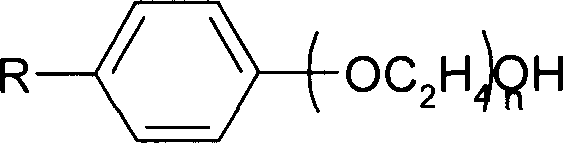

Image

Examples

Embodiment 1

[0025] Embodiment 1, with 100 parts (weight parts) by C 5 C 5 Petroleum resin, after being heated to fusing, add 60 parts (parts by weight) of concentration and be 3% sodium hydroxide solution to neutralize the aluminum chloride in the petroleum resin polymerization liquid; The mixed solution is heated to 100 ℃, and the control stirrer rotating speed is at 150 rpm to ensure that the resin liquid and the sodium hydroxide solution are mixed evenly and fully reacted, stop heating, continue stirring for about 10 minutes, then cool at room temperature, the oil phase and the water phase are separated, and the resin solidifies. Rinse with water to remove residual sodium hydroxide on the surface of the resin, and then put C 5 Petroleum resin is crushed into 10-100 μm powder with crushing equipment, soaked in 100 parts of distilled water containing 0.2% non-ionic surfactant OP-10 for 24 hours, then washed with clean water until neutral, and drained, then The petroleum resin powder wa...

Embodiment 2

[0026] Embodiment 2, with 100 parts (weight parts) by C 5 C 5 Petroleum resin, after being heated to fusing, add 20 parts (weight parts) concentration and be 12% sodium hydroxide solution to neutralize the aluminum chloride in the petroleum resin polymerization liquid; Mix solution is heated to 90 ℃, control the stirring speed of agitator at 150 rpm to ensure that the resin liquid and the sodium hydroxide solution are mixed evenly and fully reacted, stop heating, continue stirring for about 10 minutes, then cool at room temperature, the oil phase and the water phase are separated, and the resin solidifies. Rinse with water to remove residual sodium hydroxide on the surface of the resin, and then put C 5 Petroleum resin is crushed into 10-100μm powder with crushing equipment, soaked in 100 parts of distilled water containing 0.3% non-ionic surfactant fatty acid polyoxyethylene ester for 20 hours, then washed with clean water until neutral, and drained , and then the petroleum...

Embodiment 3

[0027] Embodiment 3, with 100 parts (weight parts) by C 5 C 5Petroleum resin, after being heated to fusing, add 40 parts (weight parts) concentration and be 8% sodium hydroxide solution to neutralize the aluminum chloride in the petroleum resin polymerization liquid; Mixed solution is heated to 120 ℃, control the stirrer rotating speed at 150 rpm to ensure that the resin liquid and the sodium hydroxide solution are mixed evenly and fully reacted, stop heating, continue stirring for about 10 minutes, then cool at room temperature, the oil phase and the water phase are separated, and the resin solidifies. Rinse with water to remove residual sodium hydroxide on the surface of the resin, and then put C 5 Petroleum resin is crushed into 10-100μm powder with crushing equipment, soaked in distilled water containing 0.5% non-ionic surfactant Tween for 12 hours, then washed with clean water until neutral, and drained, and then the petroleum resin The powder was vacuum dried at 80 °C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com