Yarn feeder

A yarn feeder and sensor technology, used in textiles and papermaking, thin material handling, looms, etc., can solve problems such as hindering free entry, and achieve the effect of reducing design size, easy manufacturing, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

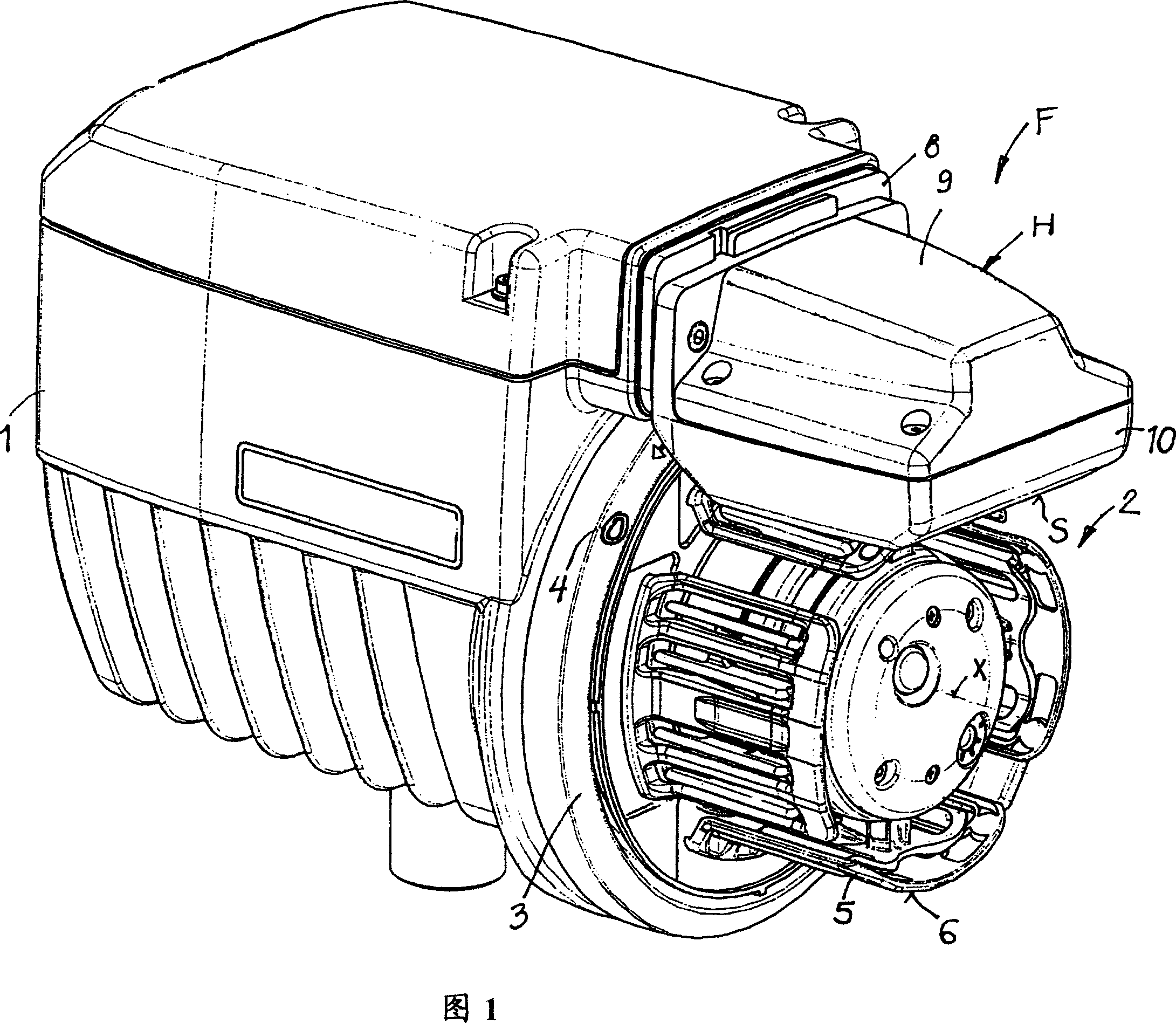

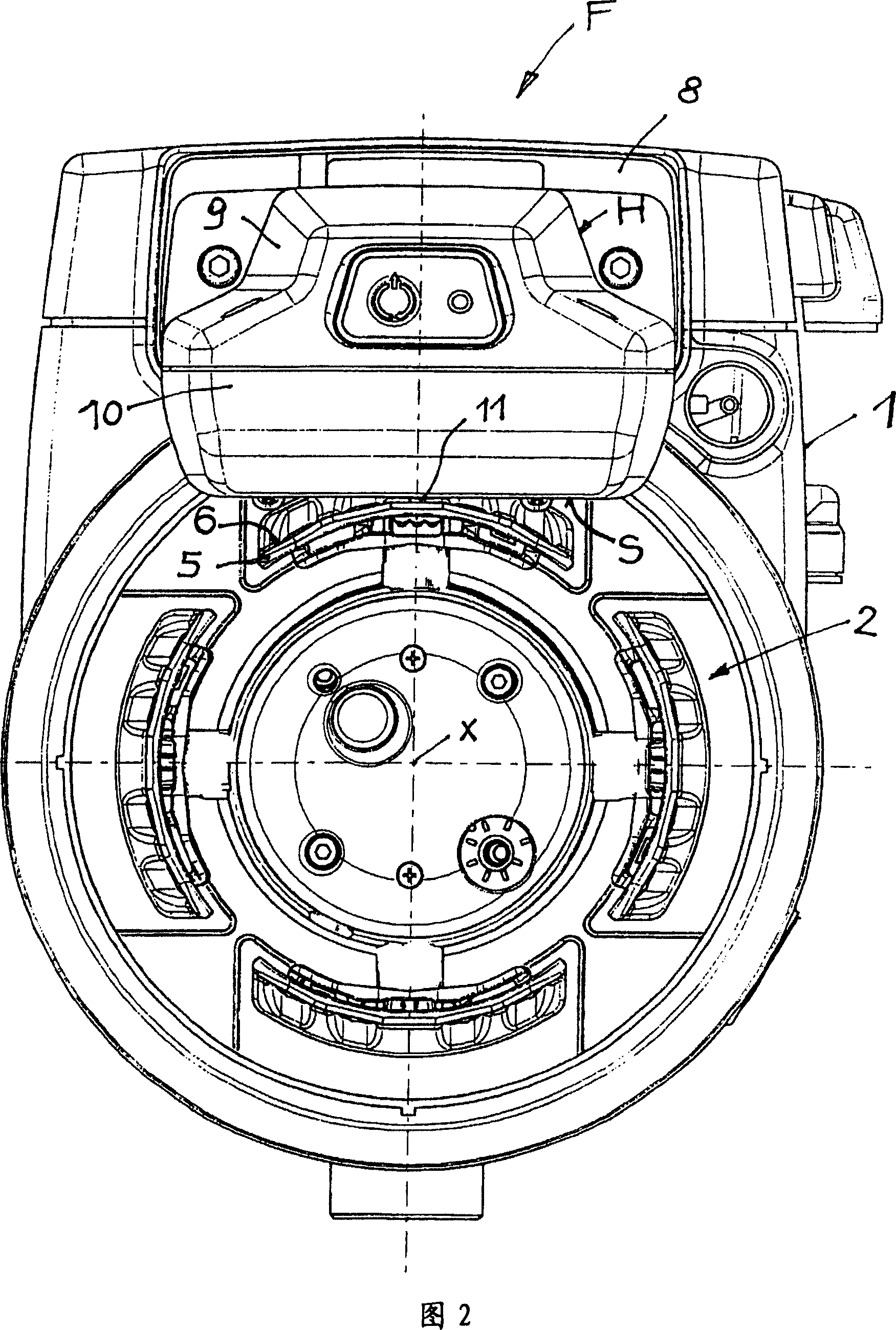

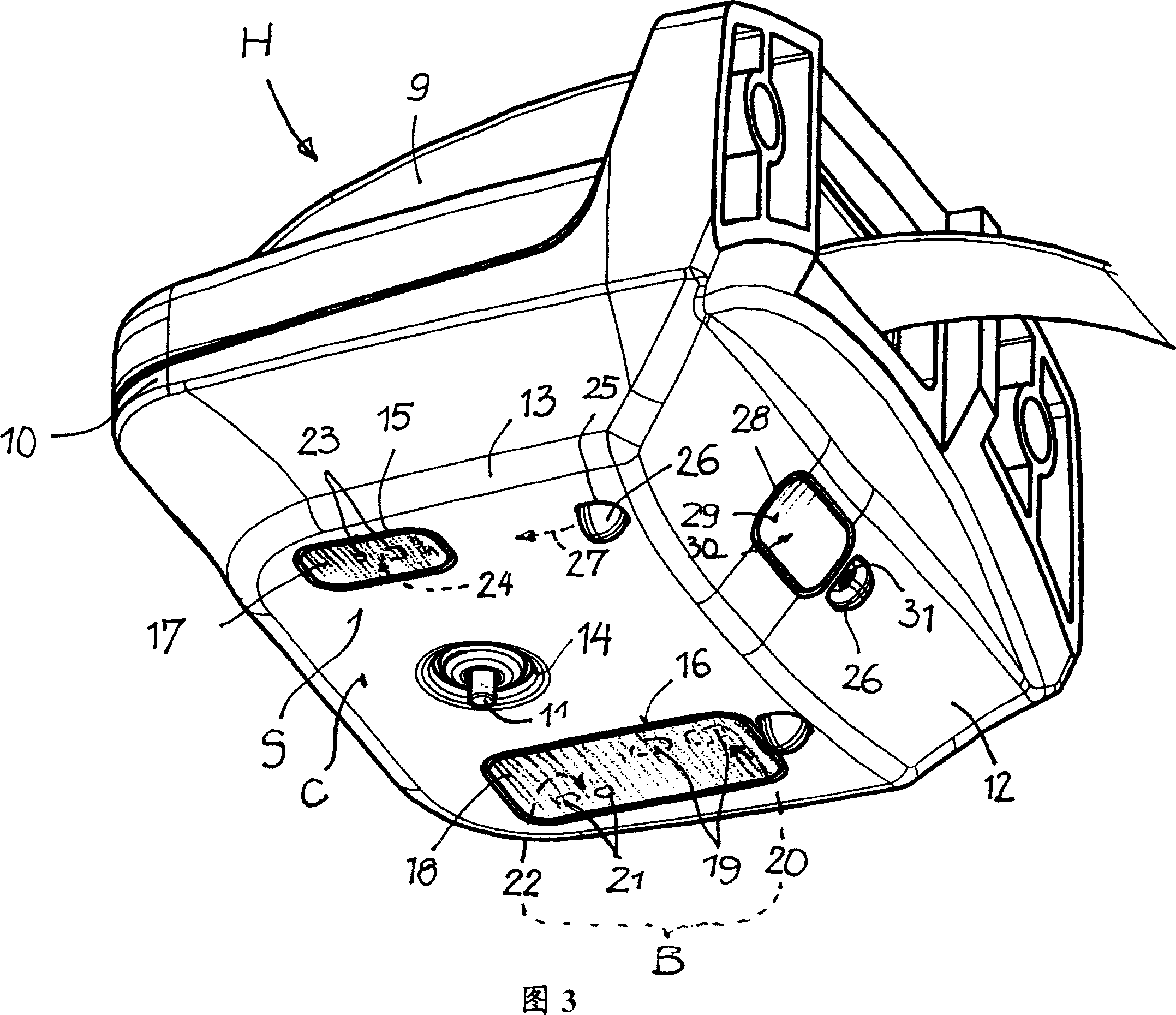

[0025] The yarn feeder F in Figs. 1 and 2, a so-called measuring conveyor, is used on a jet weaving machine (for example an air-jet loom) and comprises a housing 1 which is a section storage Body 2 provides fixed support. Between the housing 1 and the storage body 2 there is provided a rotatable winding element 3 (winding disc), and an output hole 4 from which the yarn, not shown, is drawn out and then wound on the adjacent storage body 2 or on the The separated yarns are wound on windings forming yarn packages on the storage body 2 . The storage body 2 is composed of segments 5 distributed along the circumference, each segment delimiting a concave storage area 6 . The segments 5 of the storage body are radially adjustable in order to vary the dynamic diameter of the storage body 2 .

[0026] The brake housing H is mounted to the front side of the housing 1 such that the brake housing H is associated with one segment 5 . For example the brake housing H is adjustable on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com