Touch sensing costume for intelligent robot

A technology of intelligent robot and tactile sensing, which is applied in the testing of machines/structural components, measuring devices, and the measurement of the properties and forces of piezoresistive materials, etc., can solve the problems of high cost and poor flexibility of tactile sensitive units, and achieve Low cost, good flexibility, and large detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

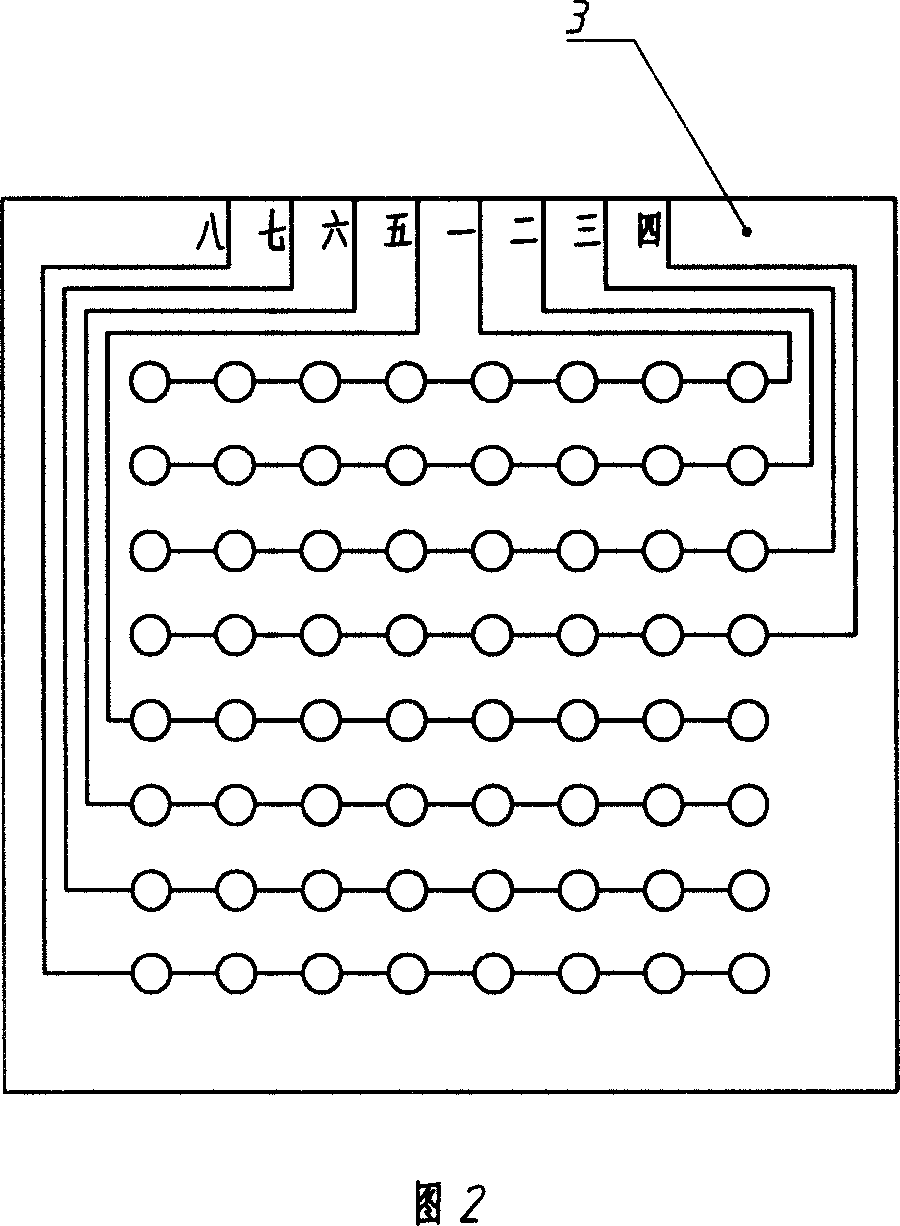

[0018] This example is based on the general description of the specific embodiments, and is a further example of the production of the thin film electrode plate and the material of the conductive rubber 20 (refer to FIGS. 2 , 3 , 4 ). In this example, the thin film electrode plate is to print silver paste on one side of the PB plastic film to form the corresponding determinant array electrode contacts (in view of the specific process of printing silver paste is a known and common technology, so in this example not further described). The conductive particles in the conductive rubber 20 of this example are glass balls plated with silver. Apparently, the conductive particles in the conductive rubber 20 can also be aluminum-plated silver or carbon black-selected according to material sources and / or other requirements.

Embodiment 2

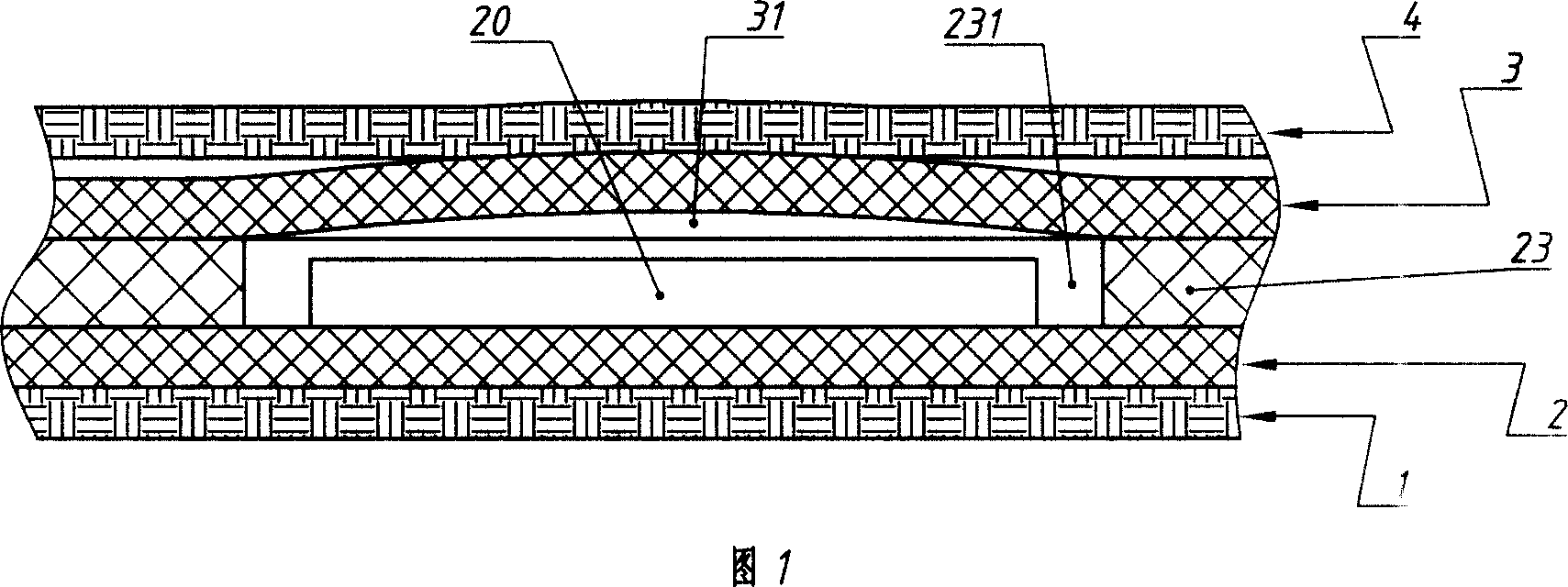

[0020] This part is based on the general description of specific embodiments or the first embodiment, and introduces the geometry and further features of the conductive rubber 20 and the insulating film spacer 23 (refer to FIGS. 1 and 4 ). Specifically, each piece of conductive rubber 20 is a round cake shape, and the holes 231 that cover them on the insulating film spacer 23 are circular holes. 23 are all pressed to the thinnest, the gap that still can not scratch between the two. That is to say, when the conductive rubber 20 is under pressure, the amount of compression that causes the change of its resistance value will not be disturbed by the insulating film spacer 23, which improves the accuracy and reliability of the present invention. At each electrode contact of the upper film electrode plate 3, there is a bubble 31 that is concave inward and protrudes outward on its opposite face (using a known hot-pressing bubble technology), and the center of the electrode contact, t...

Embodiment 3

[0024] This example is based on the general description of specific embodiments, Example 1 or Example 2, and is a supplementary improvement made to improve the durability and reliability of the present invention (refer to Figures 1 and 4). Its material is respectively the protective layer (this example uses waterproof cloth) of tarpaulin, plastic film or rubber skin on the outside of two film electrode plates (2,3) up and down. The lower protective layer 1, the lower thin-film electrode plate 2, the insulating film spacer 23, the upper thin-film electrode plate 3 and the upper protective layer 4 are pasted together by flexible glue in sequence. The flexible glue refers to the glue that still has a certain degree of flexibility after the glue is cured and coagulated (such as glue such as neoprene). In this way, the tactile sensing clothing of the intelligent robot has a certain softness in terms of bonding materials.

[0025]In this example, the conductive rubber 20 is pasted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com