Expansion dowel for fastening insulating panels

A thermal insulation material and expansion pin technology, applied in the direction of pins, screws, threaded fasteners, etc., can solve the problems of small balance value of expansion pins, thermal bridge formation, etc., and achieve an effect that is conducive to expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

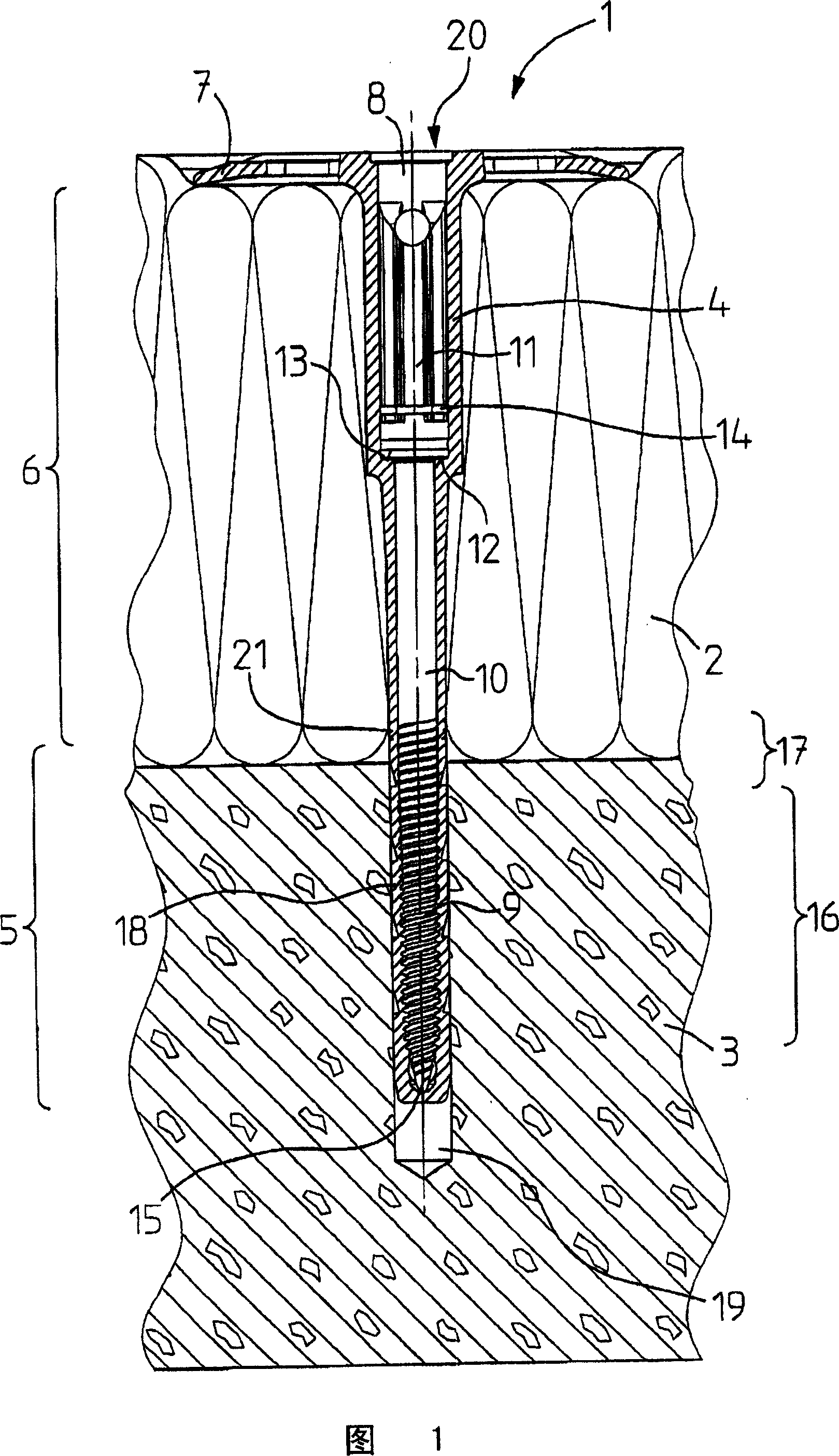

[0012] The only figure shows an expansion pin 1 according to the invention, which is used to fix a heat-insulating material plate 2 to a background 3. The expansion pin 1 has a pin sleeve 4, which has an expansion part 5, an extension section 6 and a stop disk 7 connected thereto. The expansion part may pass through a notch or expansion position arranged in the longitudinal direction, which is not shown. It is opened in the background 3 by the expansion screw 8, thus achieving the desired stopping effect. The expansion screw 8 is made of plastic and has a thread 9, a shank 10 connected thereto, and a head 11. The head 11 is supported on the pin shoulder 13 with a screw shoulder 12. The expansion screw 8 has a nominal breaking point 14 designed to surround the groove at its head. The outer diameter of the thread 9 of the expansion screw 8 protrudes from the outer diameter of the shank 10. It is slightly smaller than 1 / 3 of the pointing shank within 2 / 3 of the pointing screw tip 15....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com