Assembling structure of hung vertical rippled wheel

An assembly structure and suspension technology, which is applied to washing devices, washing machines with containers, and other washing machines, etc., can solve the problems of unsatisfactory washing effect, weakened rubbing effect of the pulsator and the washed clothes, etc., and achieve good turning effect , Improve the washing effect, the effect of high cleaning ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below through specific embodiments with accompanying drawings.

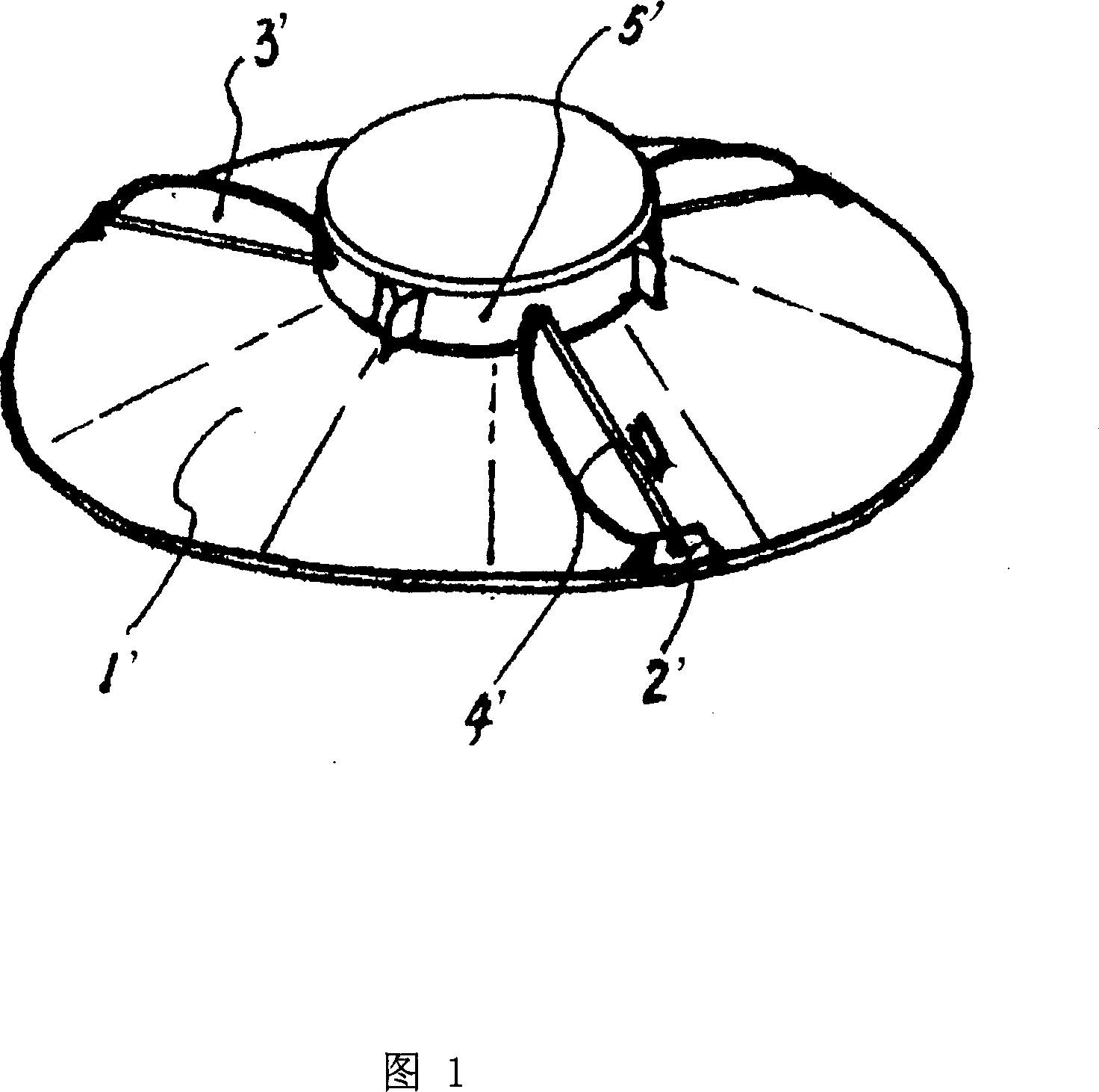

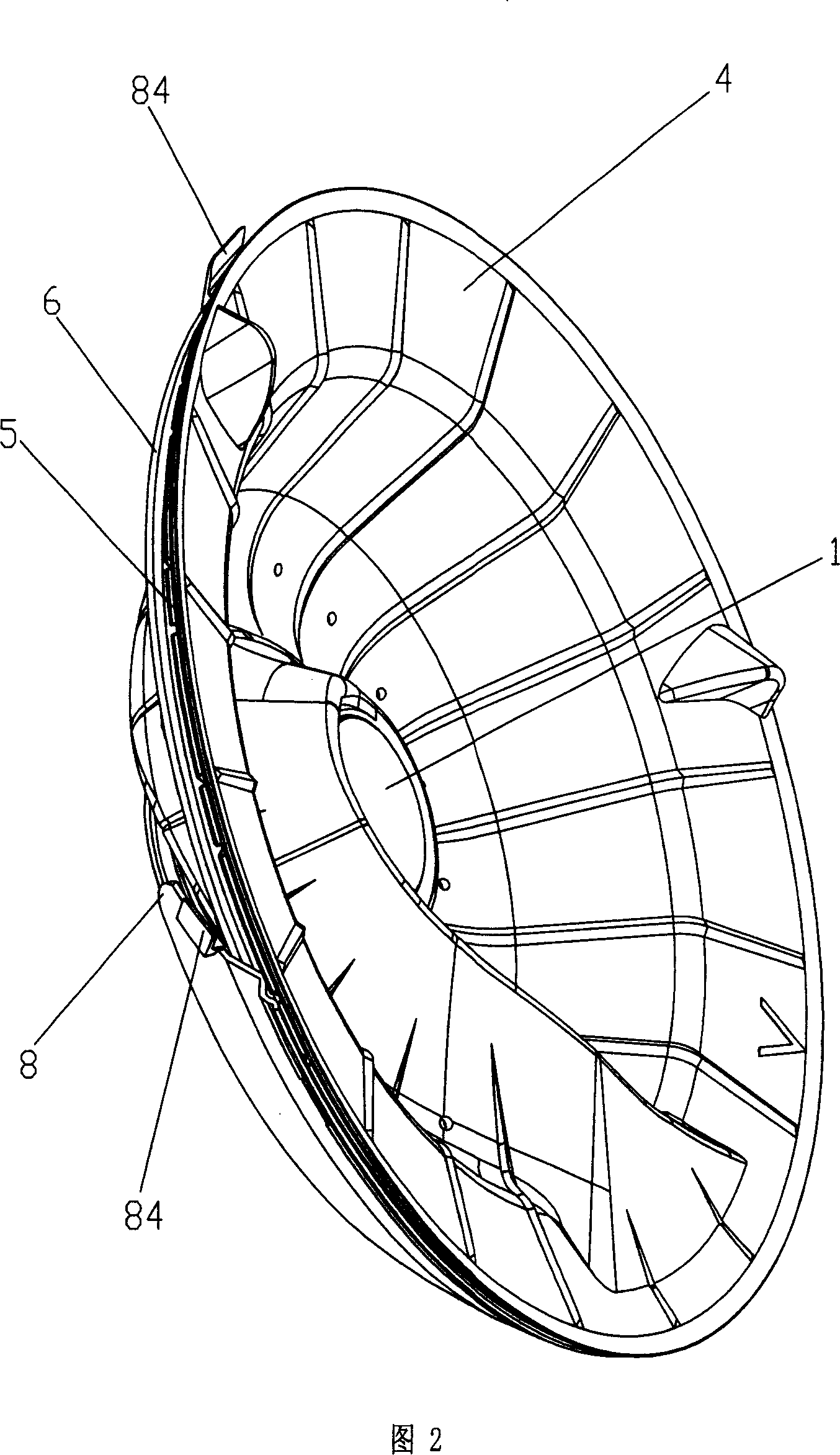

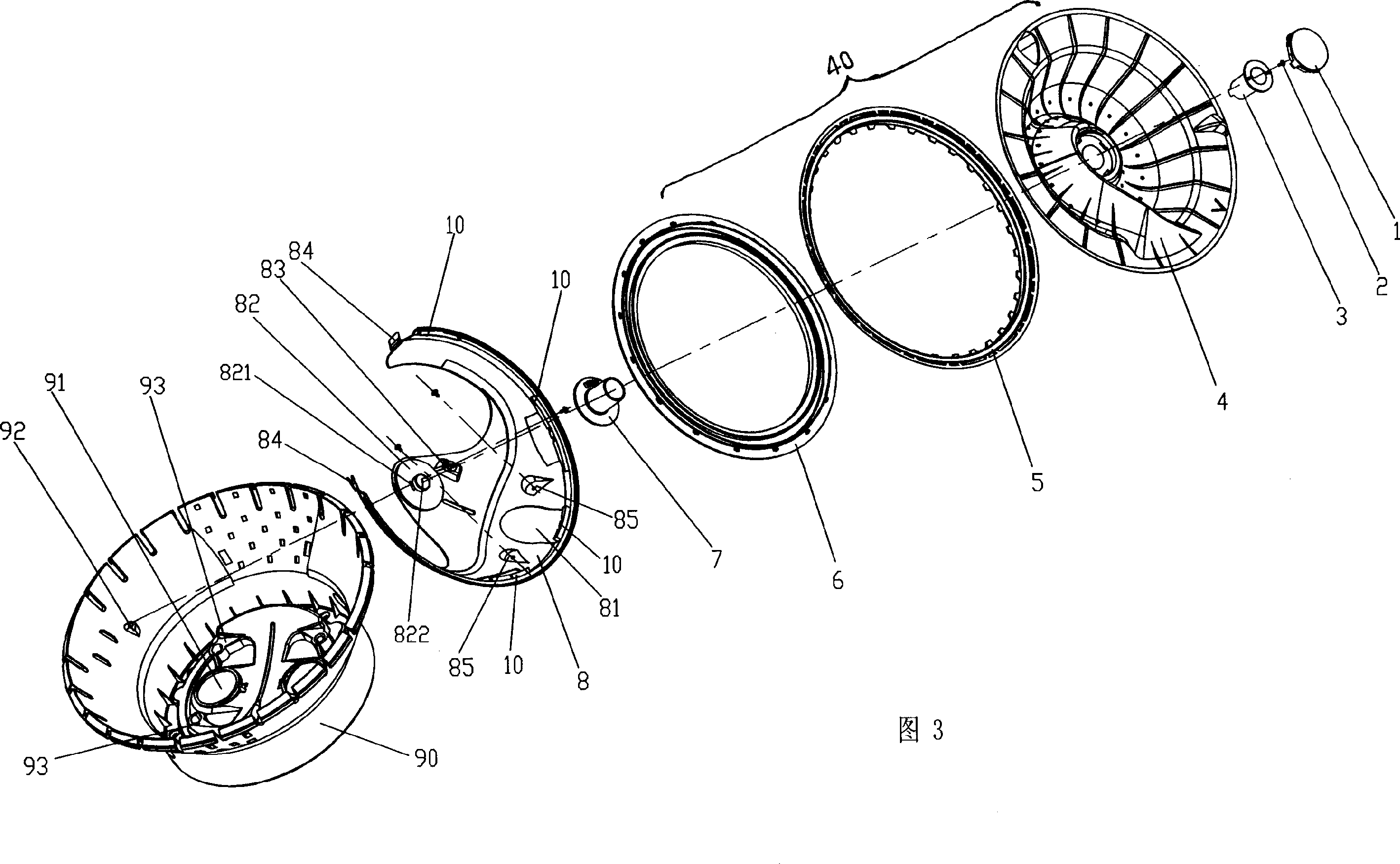

[0048] Firstly, it is explained that two suspended pulsators are installed in the inner tub of the suspended washing machine. In this specific embodiment, the structure assembly of one pulsator is used as a representative for description. What is explained here is that the structure of the inner tub of the suspension type washing machine is different from that of the existing washing machine. It mainly consists of two parts: the inner tub wall 901 and the inner tub bottom 90. It is also different from the installation of the pulsator of the existing washing machine. The two large pulsators are respectively suspended on both sides of the inner tub of the washing machine. Therefore, a part of the pulsator assembly frame is fixed on the inner tub wall, while the other part of the pulsator assembly frame is fixed On the bottom of the inner barrel, we will descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com