Rotary adjuster

A regulator, rotary technology, applied in the direction of liquid shock absorber, can solve the problems of difficult to set valve core, increase the installation space of rotary regulator, etc., to achieve the effect of expanding the scope and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

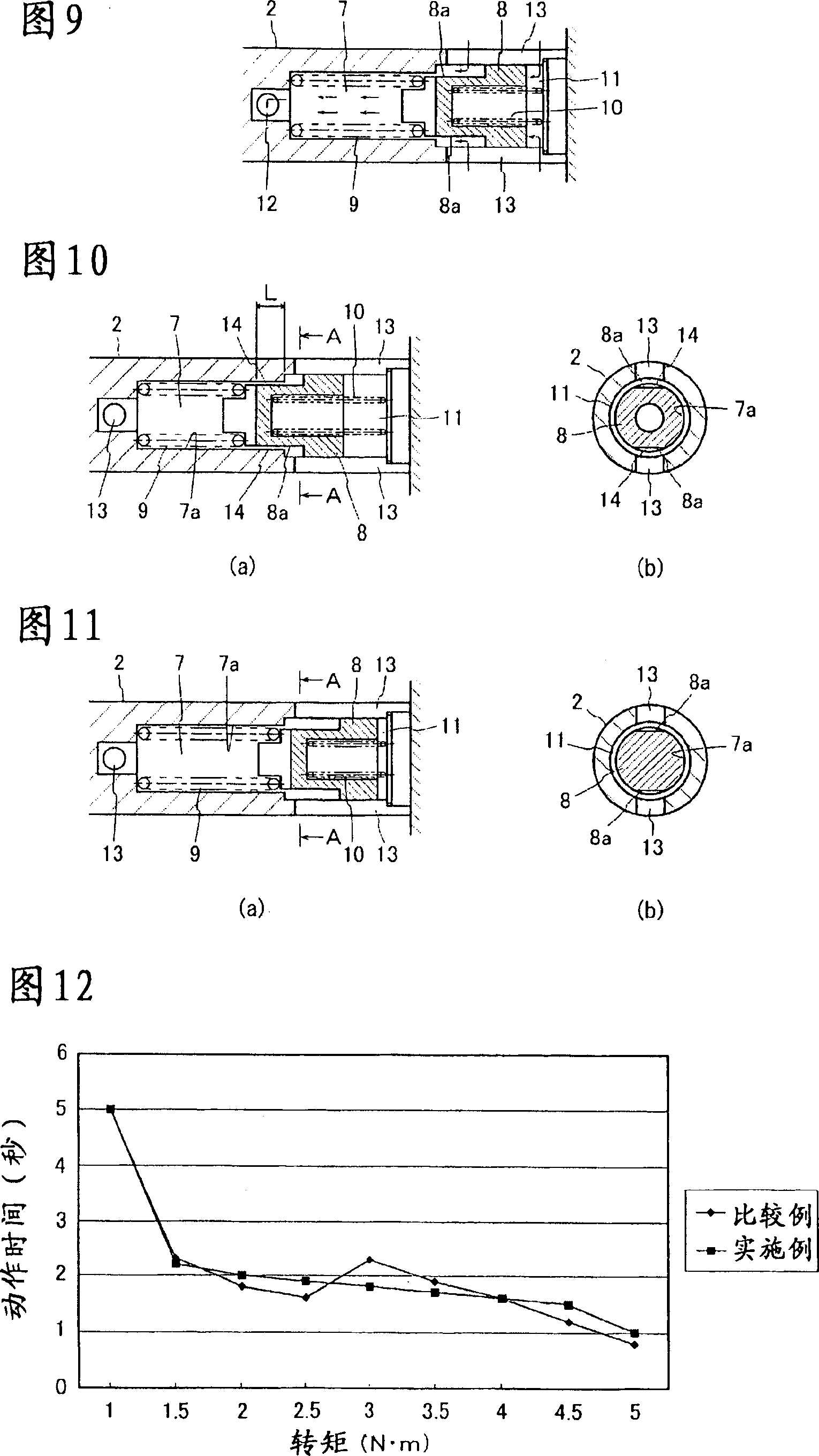

[0087] 1 to 7 are diagrams showing a rotary regulator according to Embodiment 1 of the present invention. As shown in these figures, the rotary regulator of this embodiment has a housing 1, a shaft 2, a vane 3, a partition 4, and a valve mechanism.

[0088] The shell 1 is hollow, with one end open and the other end closed. The opening of the case 1 is closed by a cover 5 . The cover 5 is installed by caulking the end of the housing 1 . The housing 1 has a partition wall 4 that partitions a space formed between the housing 1 and the shaft 2 . The housing 1 and the partition wall 4 are integrally formed by press working. In this way, the recessed portion 1a is formed in the partition wall forming portion, and the recessed portion 1a functions as a joint portion (see FIGS. 3 to 5 ). Viscous fluid such as silicone oil is filled in the casing 1 .

[0089] The shaft 2 is arranged rotatably relative to the housing 1 in the housing 1 . Blades 3 integrally formed with the shaft 2...

Embodiment 2

[0107] The shape of the spool 8 of the rotary regulator of this embodiment is different from that of the rotary regulator of the first embodiment. That is, the spool 8 of this embodiment has a tapered surface 8b on its outer periphery as shown in FIGS. 14 and 15 .

[0108] FIG. 14 shows the state before the valve core 8 moves forward in the working chamber 7 , and FIG. 15 shows the state after the valve core 8 moves forward in the working chamber 7 . As shown in these figures, according to the valve mechanism having the spool 8, as the movement distance of the spool 8 that moves forward in the working chamber 7 increases, the wall surface formed on the peripheral wall 7a of the working chamber 7 and the spool 8 The area of the flow path 14 between the tapered surfaces 8b is reduced, thereby increasing the throttling amount. Therefore, the same effect as that of the first embodiment can be obtained in this embodiment as well.

Embodiment 3

[0110] The shape of the spool 8 of the rotary regulator of this embodiment is different from that of the rotary regulator of the first embodiment. That is, as shown in FIG. 16, the valve body 8 of this embodiment has a substantially V-shaped groove 8c on its outer periphery.

[0111] According to the valve mechanism having the spool 8, as the movement distance of the spool 8 moving forward in the working chamber 7 increases, the flow path formed between the wall surface of the peripheral wall 7a of the working chamber 7 and the groove 8c of the spool 8 The area of 14 is reduced, thereby can increase throttling amount. Therefore, the same effect as that of the first embodiment can be obtained in this embodiment as well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com