Surface protective sheet

A technology of surface protection film and plastic film, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of color change, yellowing color, content increase, etc., and achieve good anti-ultraviolet performance, The effect of less yellowing and maintaining the same color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

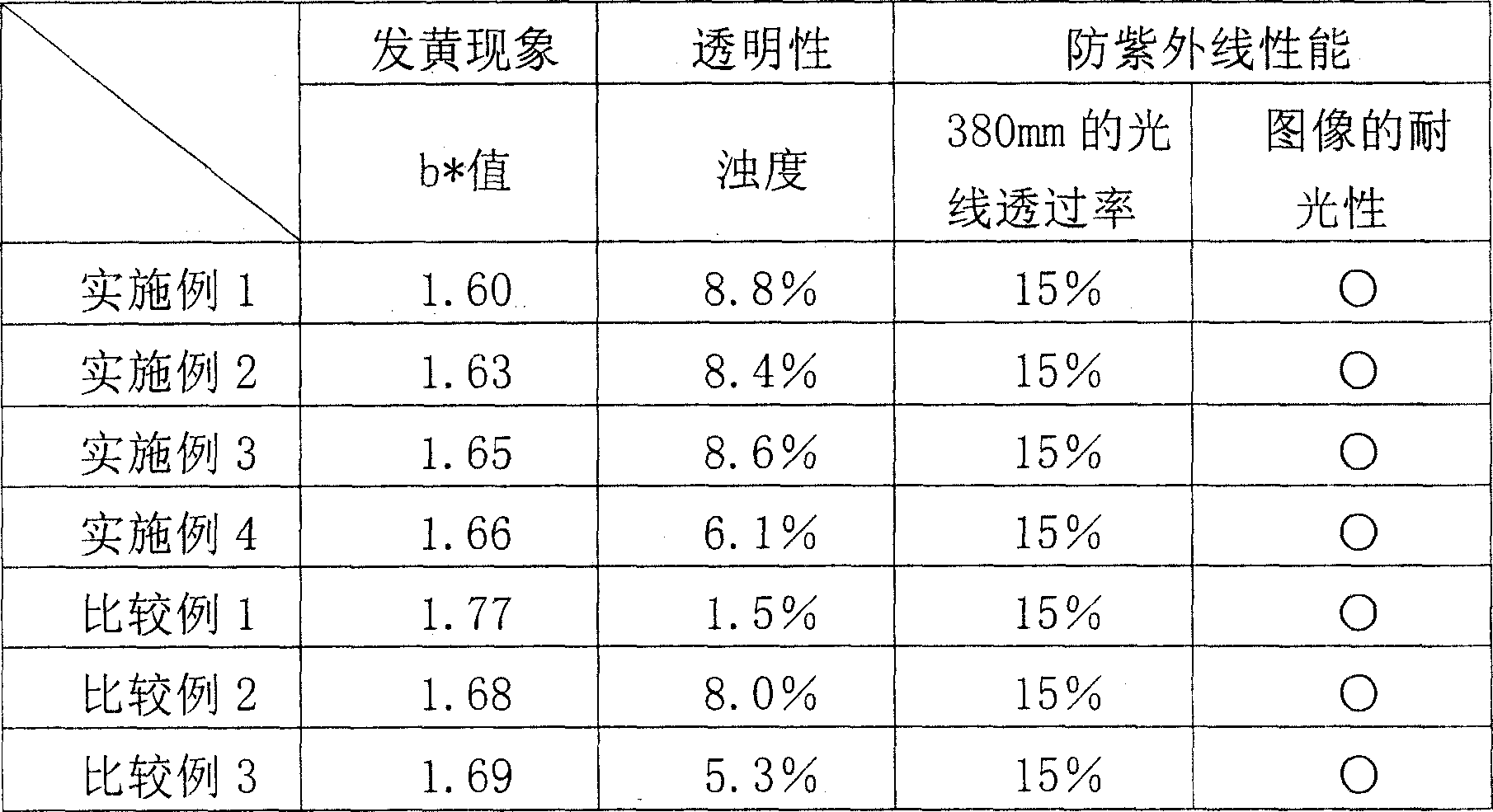

Examples

Embodiment 1

[0042] As a transparent plastic film, in b * On one side of a polyethylene terephthalate film with a value of 1.0 and a thickness of 188 μm, a coating solution for an ultraviolet protection layer of the following formulation was applied, dried, and irradiated with ultraviolet rays by a high-pressure mercury lamp to form a 4 μm layer. Thick anti-ultraviolet layer, makes the surface protective film of embodiment 1.

[0043]

[0044] ・Ionizing radiation curable resin composition (solid content 100%) 15 parts

[0045] (DIABEAM UR6530: manufactured by MITSUBISHI RAYON Co., Ltd.)

[0046] ·Ultraviolet absorber (formula weight 315.8) 1.2 parts

[0047]

[0048] (KEMISORB72: manufactured by CHEMIPRO Chemical Co., Ltd.)

[0049] ·Ultraviolet absorber (formula weight 323.4) 0.9 parts

[0050]

[0051] (KEMISORB79: manufactured by CHEMIPRO Chemical Co., Ltd.)

[0052] ・Spherical microparticles (silicon dioxide) (average particle size: 6 μm) 0.15 parts

[0053] (HIPRESICA TS-N...

Embodiment 2

[0064] The surface protection film of Example 2 was produced in the same manner as in Example 1 except that the coating liquid for an ultraviolet protection layer of Example 1 was changed to the coating liquid for an ultraviolet protection layer of the following formulation.

[0065]

[0066] ・Ionizing radiation curable resin composition (solid content 100%) 15 parts

[0067] (DIABEAM UR6530: manufactured by MITSUBISHI RAYON Co., Ltd.)

[0068] ·Ultraviolet absorber (formula weight 315.8) 1.2 parts

[0069]

[0070] (KEMISORB72: manufactured by CHEMIPRO Chemical Co., Ltd.)

[0071] ·Ultraviolet absorber (formula weight 323.4) 0.9 parts

[0072]

[0073] (KEMISORB72: manufactured by CHEMIPRO Chemical Co., Ltd.)

[0074] · Spherical microparticles (cross-linked acrylic resin) 0.25 parts

[0075] (average particle size 5 μm) (MB20X-5: manufactured by Sekisui Chemical Industry Co., Ltd.)

[0076] ・Organopolysiloxane (solid content 100%) 0.1 parts

[0077] (BYK307: BYK-...

Embodiment 3

[0086] Using the coating solution for the ultraviolet protection layer of Example 1, without adding organic polymolecular silicon ether, and changing the addition amount of the ionizing radiation-curable resin composition to 15.1 parts, except that, the same as in Example 1, the preparation Became the surface protection film of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com