Scanning thermal microscope probe

A scanning thermal microscope and probe technology, which is applied in the field of scanning thermal microscope probes, can solve problems such as the inability to meet the temperature characterization of nanostructures, and achieve the effects of improving spatial resolution and thermal sensitivity, reducing costs, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

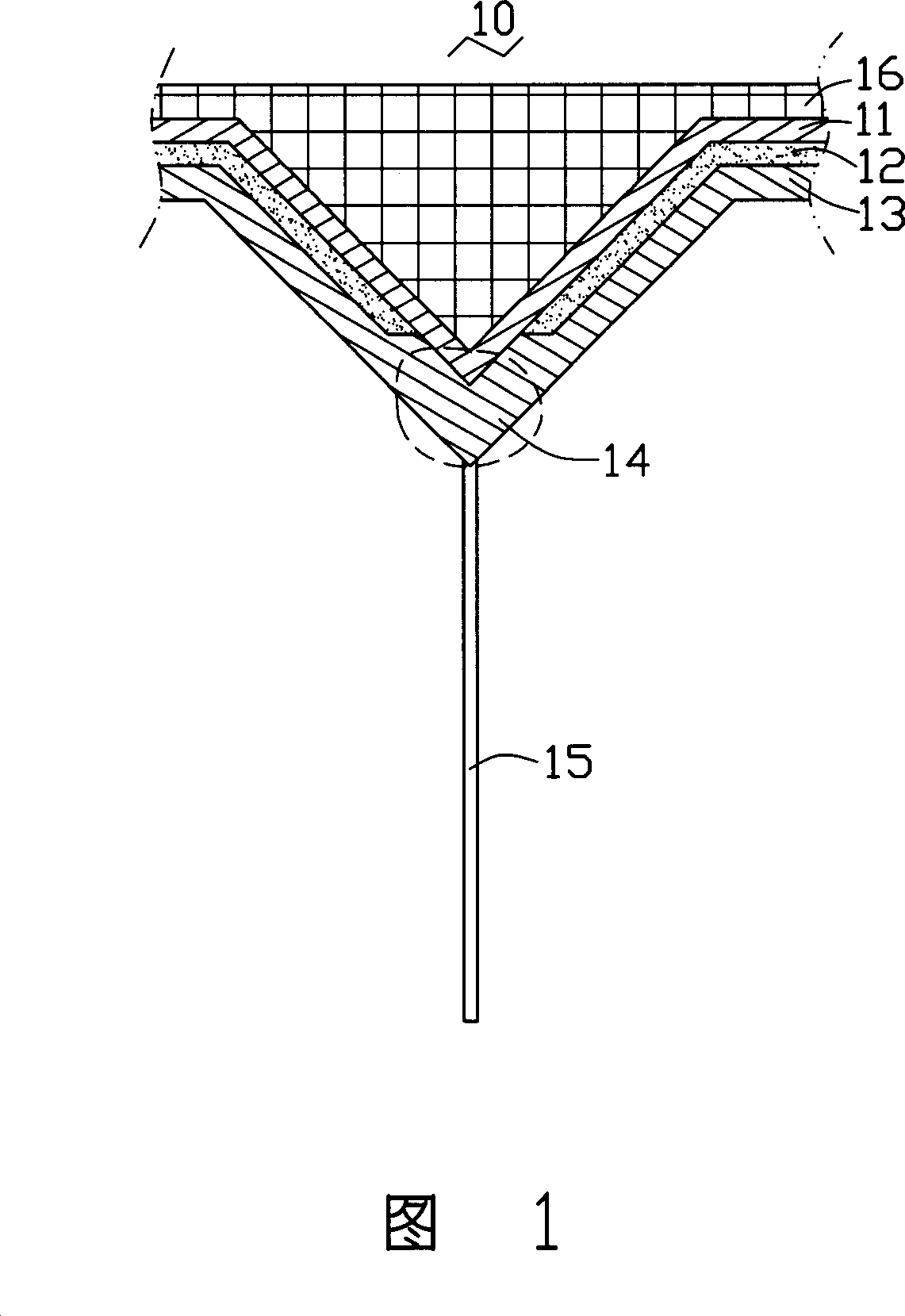

[0012] Please refer to Fig. 1 , the scanning thermal microscope probe 10 provided for the embodiment of the present invention includes: a cantilever 16; a first conductive layer 11 formed on the surface of the cantilever 16; an insulating layer 12 covering the cantilever 16 The surface of the first conductive layer 11 has a through hole; a second conductive layer 13 is covered on the surface of the insulating layer 12, and the first conductive layer 11 and the second conductive layer 13 are connected at the through hole to form a a thermocouple area 14; and a carbon nanotube 15 formed in the thermocouple area 14, one end is connected to the second conductive layer 13 at the thermocouple area 14, and the other end is a free end. Preferably, the carbon nanotubes 15 extend outwardly substantially perpendicular to the thermocouple region 14 .

[0013] The thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com