Clamp for fixing magnetic head assembly and measuring method of rising quantity using the same

An assembly and fixture technology, which is applied to the functional test of the magnetic head, the hydrodynamic spacing of the head, the configuration/installation of the recording head, etc., can solve the problems of the inability to locate the slider and the complicated positioning of the magnetic head assembly 503, etc. Achieve the effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

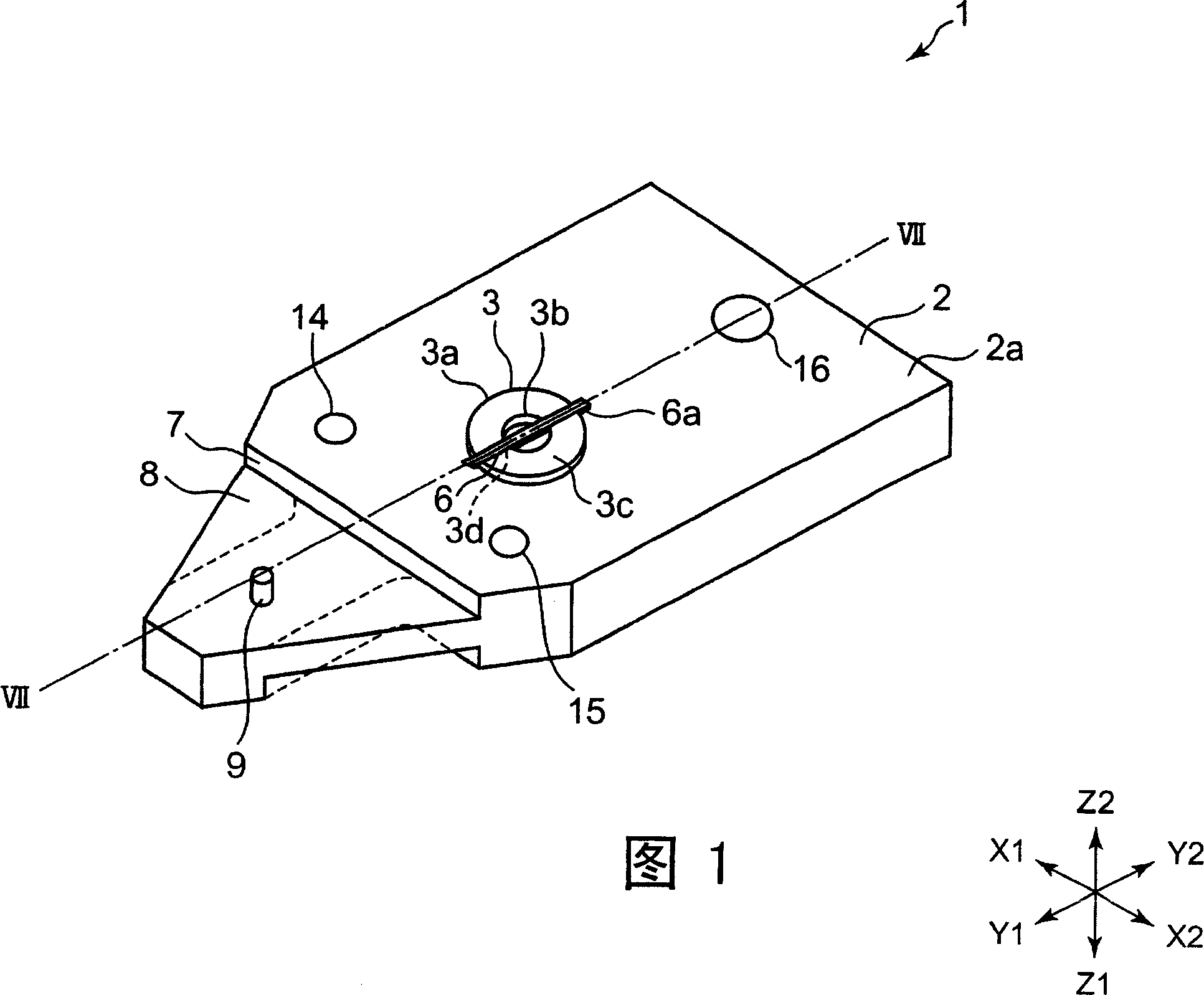

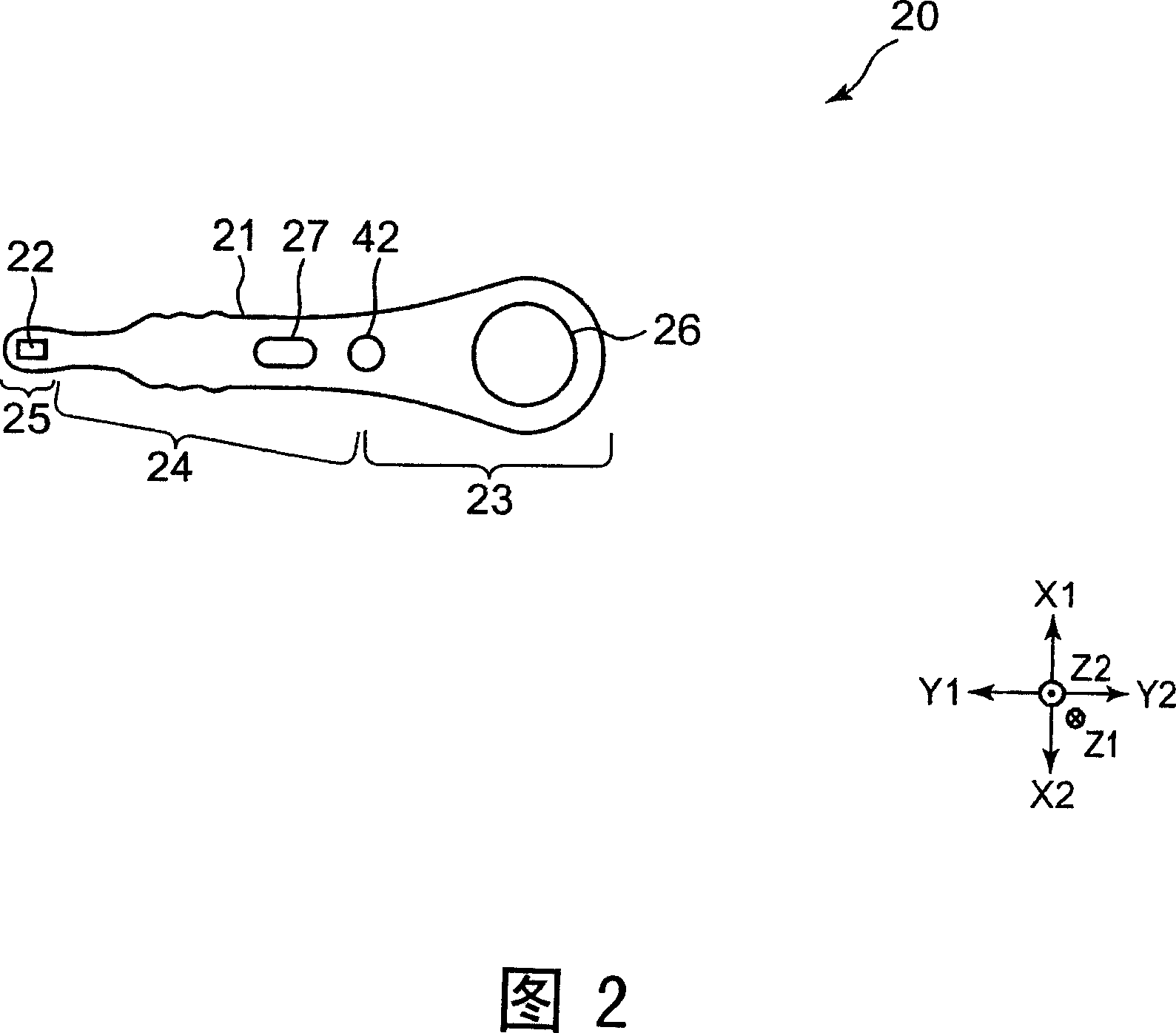

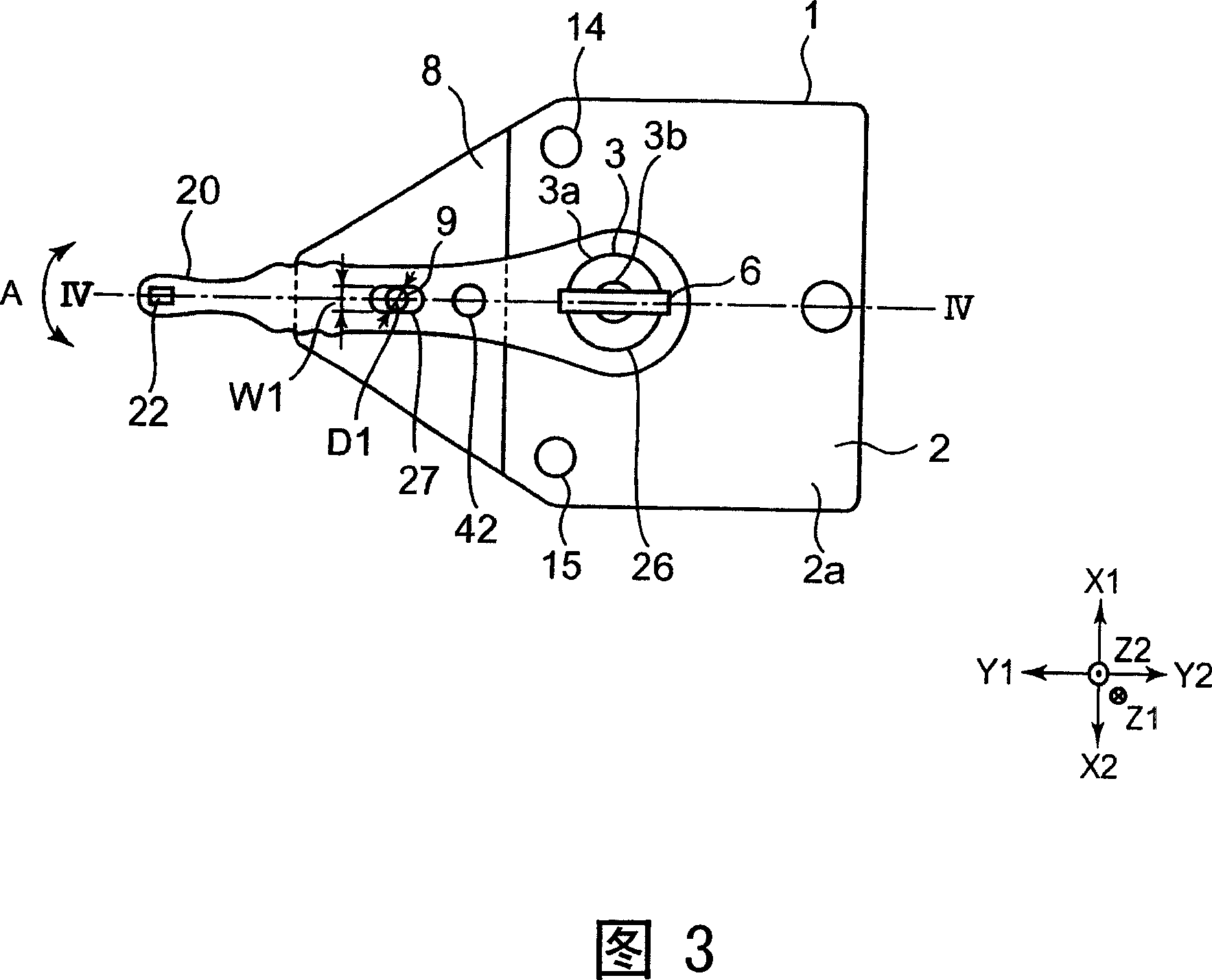

[0052] 1 is a perspective view showing a first embodiment of a fixing jig used when measuring the floating amount of the magnetic head assembly of the present invention from the upper side, and FIG. 2 is a perspective view showing the fixing jig engaged in FIG. A plan view of the magnetic head assembly at the jig, FIG. 3 is a plan view showing a state in which the magnetic head assembly shown in FIG. 2 is fixed at the fixing jig shown in FIG. 1 , and FIG. 4 is cut along line IV-IV of FIG. 3 It cuts the sectional view, and is a schematic diagram of cutting the axis center of the glass disk used in use and the axis of the fixed glass disk rotation drive on the extension line of the above-mentioned IV-IV line.

[0053] The fixing jig 1 shown in FIG. 1 is a magnetic head assembly to which a slider (slider) is fixedly installed. The jig used to measure the floating amount of the head floating from the glass disk is a fixing jig for fixing the magnetic head assembly.

[0054] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com