Carbon crystal electrothermo-material and preparing method

A carbon crystal and carbon crystal powder technology, which is applied in the field of carbon crystal electric heating materials and their preparation, can solve the problems of endangering life safety, difficulty in ensuring construction quality, and risk of using carbon fiber materials at temperature, and achieves the effect of increasing surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0044] The modulus indicators of the selected carbon fiber raw materials are: acryl cyano group, resistance 10K modulus, fiber length 3-5mm, no glue, soluble in water.

[0045] The preparation of carbon crystal powder comprises the following steps successively:

[0046] a) Soak the carbon fiber raw material in prepared thinner, which can be mixed with 35% by weight xylene, 55% acetone solution and 10% dipropylene glycol dimethyl ether solution to drive out impurities;

[0047] b) Put the above raw materials into a clean container and bake at 80°C to ensure that the thinner is completely volatilized;

[0048]c) Use a strong magnetic field above 30,000 gauss to strengthen the electrode polarity;

[0049] d) Deep processing with a high-power electronic ball mill, repeated several times, until a uniform powder body with a diameter of 1-2μ and a large mesh (about 1500 mesh) is produced to form a carbon crystal raw material.

preparation Embodiment 2

[0051] The modulus indicators of the selected carbon fiber raw materials are: acrylonitrile, resistance 10K modulus, fiber length 4-6mm, no glue, soluble in water. Carbon crystal powder is prepared according to the above method to form a carbon crystal raw material.

[0052] Carbon crystal plate preparation example 1

[0053] a) Preparation of raw materials:

[0054] 1. The above-mentioned carbon crystal powder is mixed with ordinary pulp in a ratio of 3% by weight, and the viscosity additive epoxy resin with a weight percentage of 3% of the total amount of pulp is added, and homogenized with a high-speed homogenizer;

[0055] ②. Carbon crystal paper is produced on small paper-making equipment as a raw material for making carbon crystal plates;

[0056] ③. Use the cutting equipment to cooperate with the modulus detection device to select the base paper whose carbon crystal content meets the product requirements from the large roll of carbon crystal paper, and cut it into the...

preparation Embodiment 3

[0081] The above-mentioned carbon crystal powder is mixed with ordinary pulp in a proportion of 11% by weight, and a viscosity aid epoxy resin with a weight percentage of 3% of the total amount of pulp is added, homogenized with a high-speed homogenizer, and then according to the carbon crystal plate embodiment The steps in 1 prepare the carbon crystal plate.

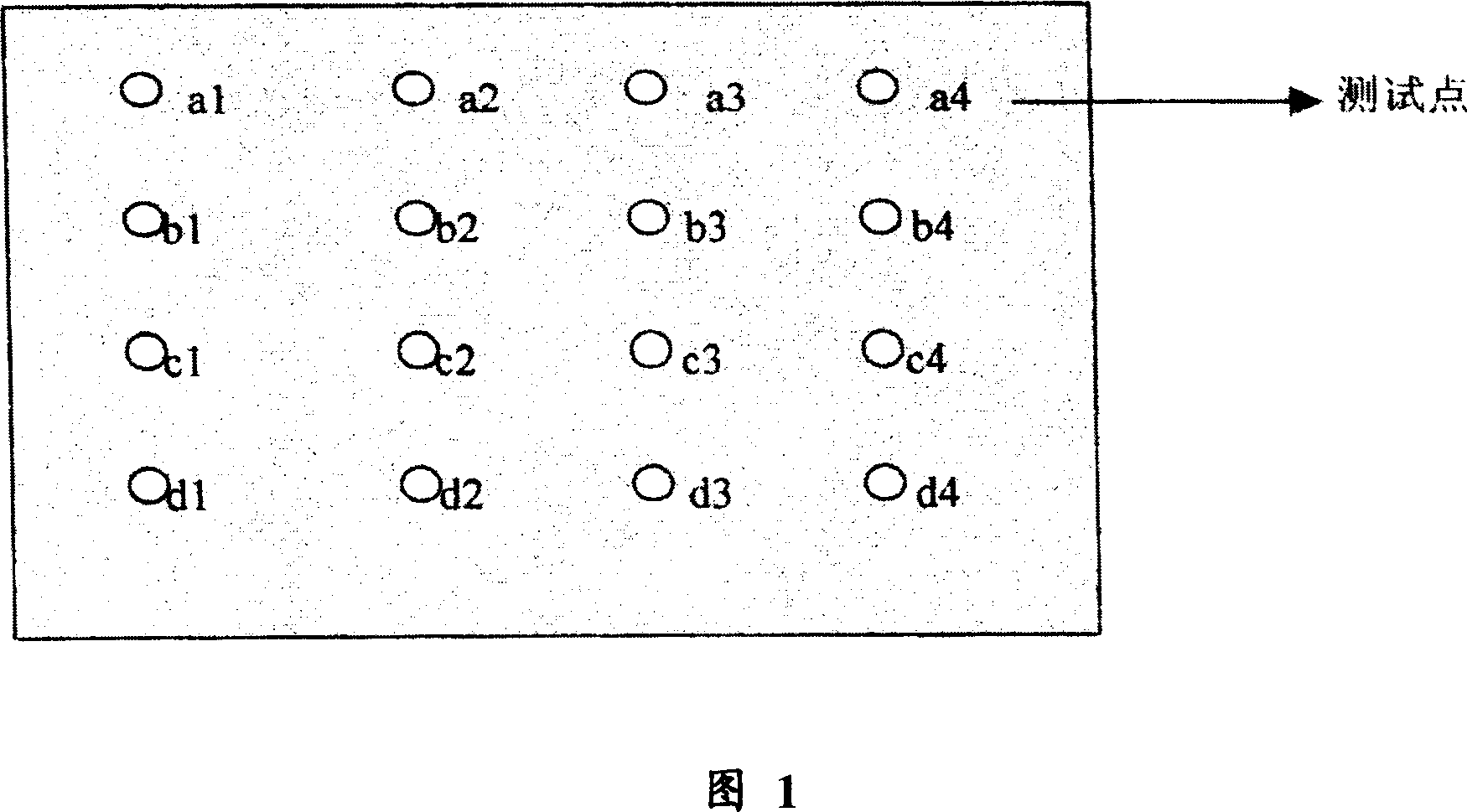

[0082] For the carbon crystal plate prepared by the above method, the heating time test, the surface temperature uniformity test and the surface insulation test were respectively carried out, and the obtained results are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com