Tyre mould

A tire mold and mold technology, applied in the field of molds, can solve the problems of high manufacturing cost, huge vulcanization equipment, large mold quality, etc., and achieve the effects of reducing production cost, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

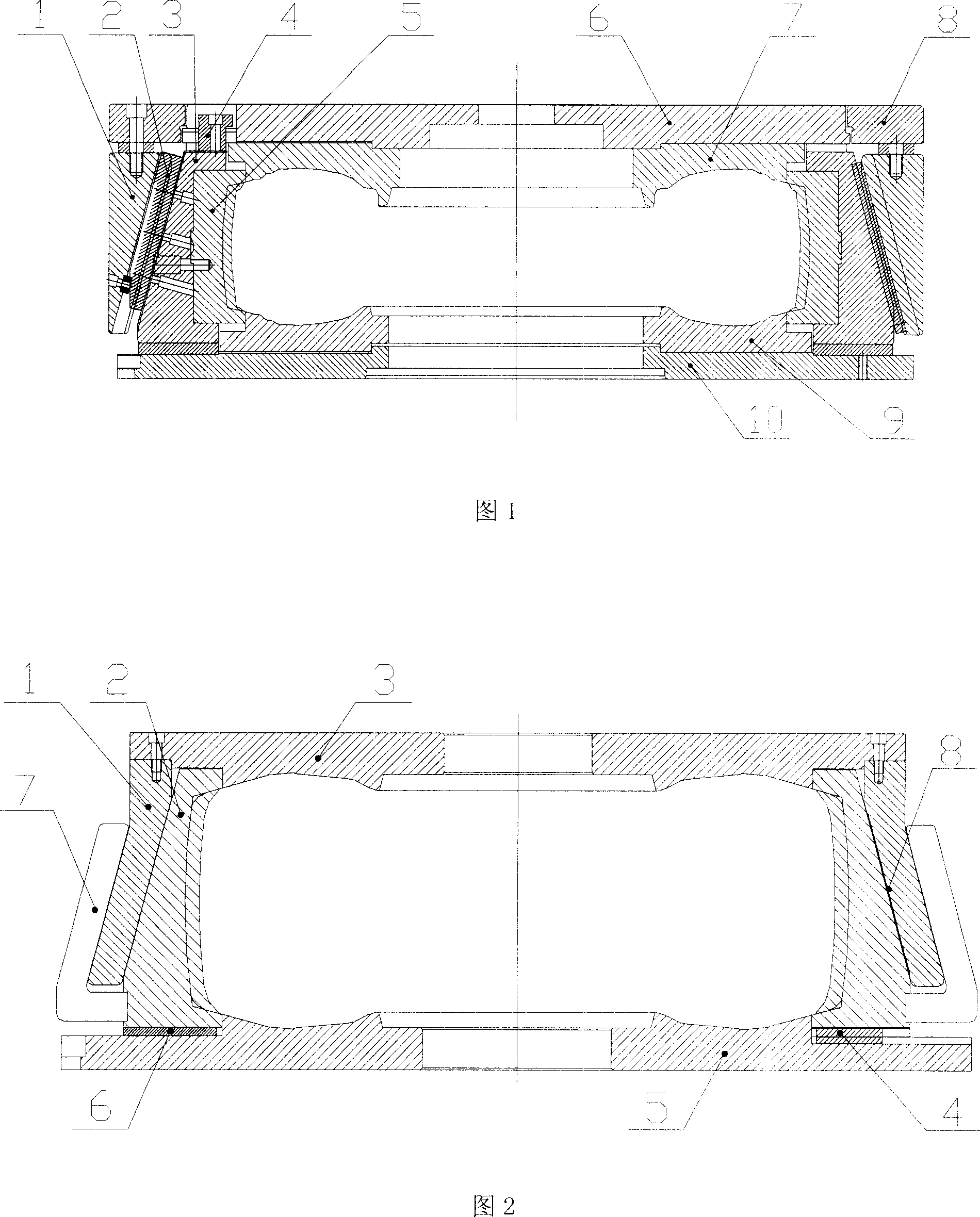

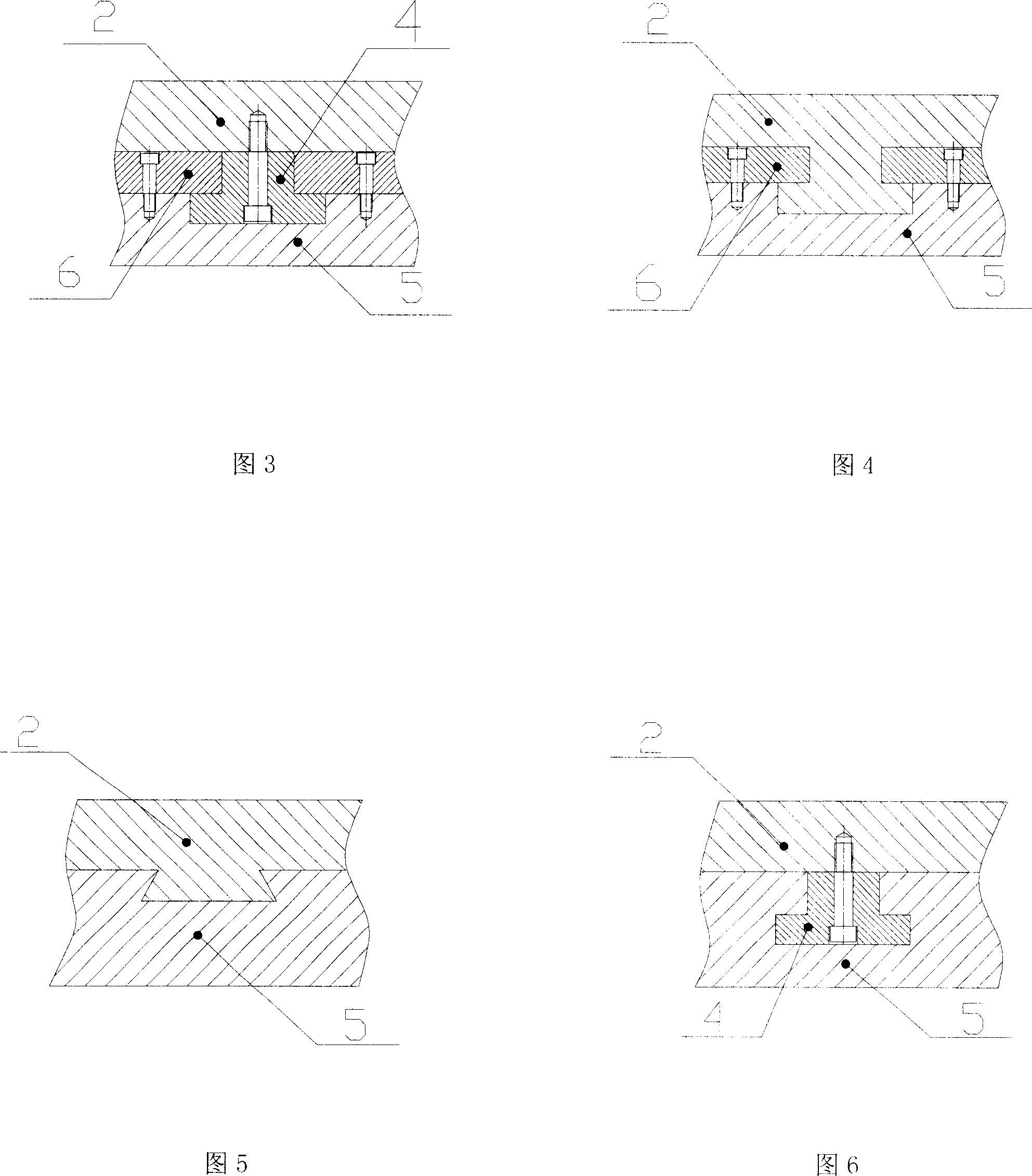

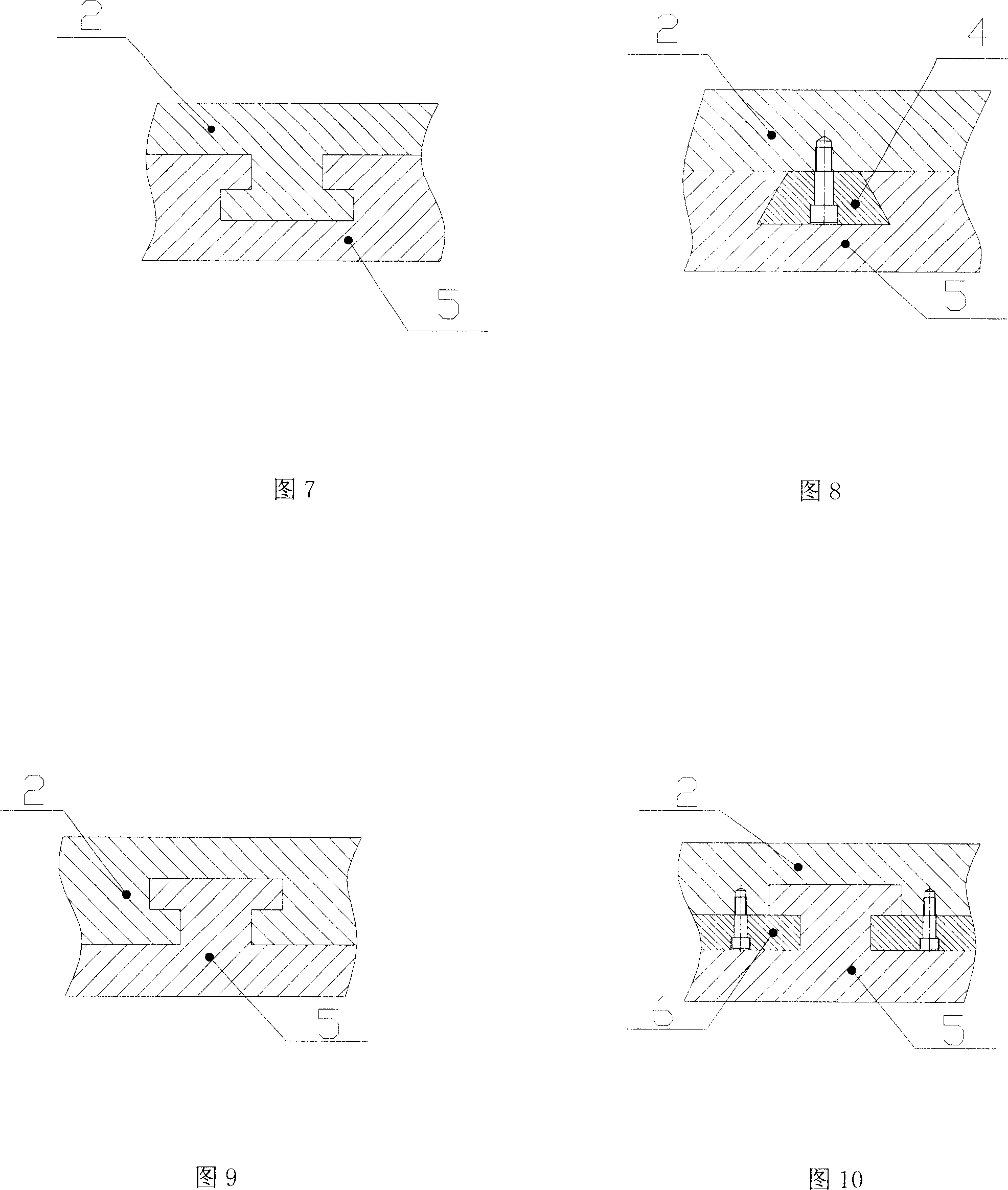

[0030] As shown in Figure 2, 1 is the middle mold cover, 3 is the upper side plate, 4 is the slider, 5 is the lower side plate, 6 is the anti-friction block, 2 is the pattern block, which are located on the upper side plate 3, the lower side plate 5 to form a tire crown pattern, pattern blocks 2 are evenly distributed on the same circumference, and a slide block 4 is fixed at the bottom thereof. The inclined surface of the outer surface of the pattern block 2 and the inclined surface of the inner surface of the middle mold sleeve 1 are relatively matched and slid, and the pattern block 2 and the lower side plate 5 are positioned and connected in the axial direction of the mold, and there is no axial displacement between them. 1. During the mold closing process, each pattern block can simultaneously reciprocate synchronously on the upper part of the lower side plate 5 along the radial direction of the mold. Plate 3 moves up and down. A plurality of pattern blocks 2 are folded ...

Embodiment 2

[0036] The connection mode between the pattern block 2 and the lower side plate 5 in the axial direction of the mold is shown in Figure 4. The protrusion at the bottom of the pattern block 2 is integrated with the pattern block 2. The section of the protrusion is an inverted "T" shape, and the lower side plate The inverted "T"-shaped groove on the upper part of 5 is formed by the groove on the upper part of the lower side plate 5 and two friction-reducing blocks 6 fixedly installed along the radial edge of the groove.

[0037] Others are the same as embodiment 1.

Embodiment 3

[0039] The connection mode between the pattern block 2 and the lower side plate 5 in the axial direction of the mold is shown in Figure 5. The protrusion at the bottom of the pattern block 2 is integrated with the pattern block 2, and the section of the protrusion is dovetail-shaped. The upper part of the lower side plate 5 The groove is also correspondingly a dovetail groove.

[0040] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com