Industrial production method for high-purity low molecular weight soybean obligopeptide powder

A soybean oligopeptide, high-purity technology, applied in protein food processing, vegetable protein processing, protein food ingredients and other directions, can solve the problems of difficult separation methods, difficult processing, realization, etc., to reduce hypertension, reduce blood lipids, enhance immune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

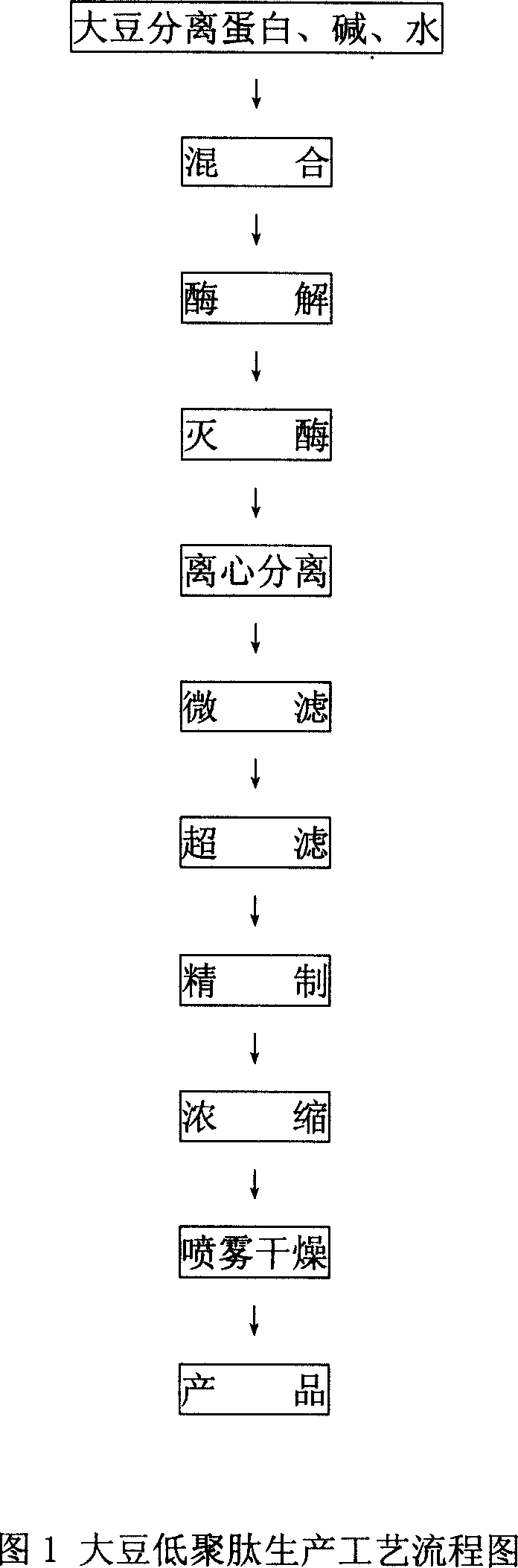

Image

Examples

Embodiment 1

[0043] Add 6000L deionized water and 500kg soybean protein isolate powder to a 10000L hydrolysis tank with a water interlayer, and add materials while adding water to prevent agglomeration from too fast mixing. Stir well, and adjust the pH to 7.0-9.0 with NaOH solution. Add 10kg of compound protease, and after enzymolysis at 40-60°C for 6 hours, heat the enzymolysis solution at 135°C for 15 seconds. The degree of hydrolysis of protein reaches 55%. The soybean protein enzymatic hydrolyzate is separated by a combined separation system, that is, centrifuged by a disc separator to obtain pulp residue and centrifugal supernatant. Collect the supernatant for later use. Use a ceramic membrane microfiltration device with a pore size of 0.1 μm-0.5 μm for filtration and separation to obtain the retentate and permeate, and collect the permeate for future use. Finally, filter the ultrafiltration permeate obtained in the previous step with a hollow fiber membrane ultrafiltration device ...

Embodiment 2

[0045] Take 800kg soybean protein isolate as raw material, add protease and carry out enzymolysis processing according to the ratio of enzyme used in Example 1, finally obtain 380kg soybean oligopeptide powder. The analysis results show that the soybean peptide content in the product: 81.3%; the free amino acid content: 2.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com