Permanent magnetic brushless DC four-quadrant electric machine

A permanent magnet brushless DC, four-quadrant technology, applied in the magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure and other directions, can solve the problem of high processing cost, achieve high reliability, Good systematization and the effect of saving material copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

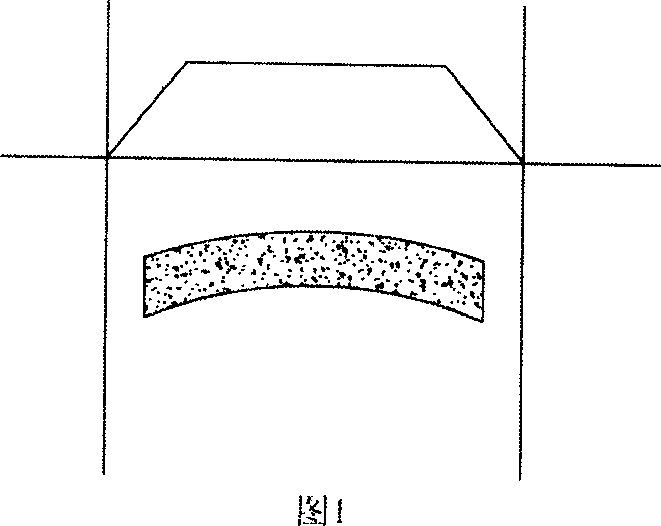

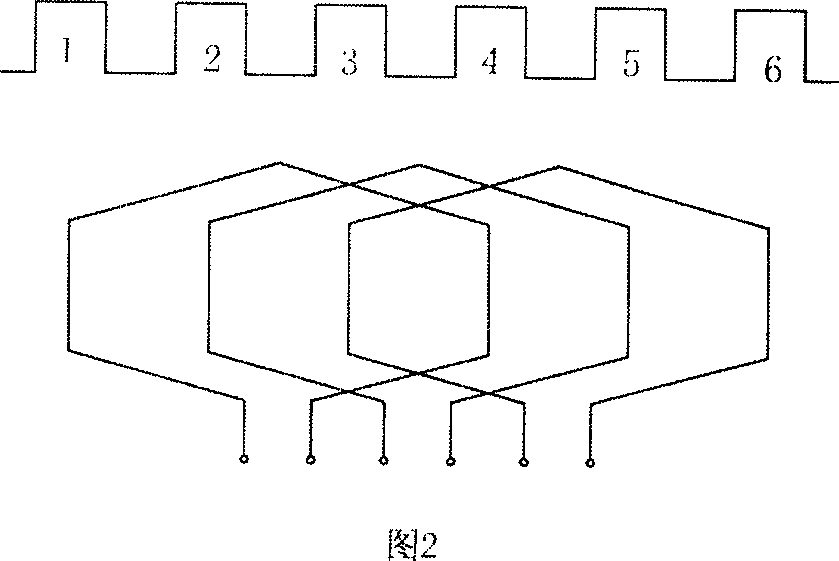

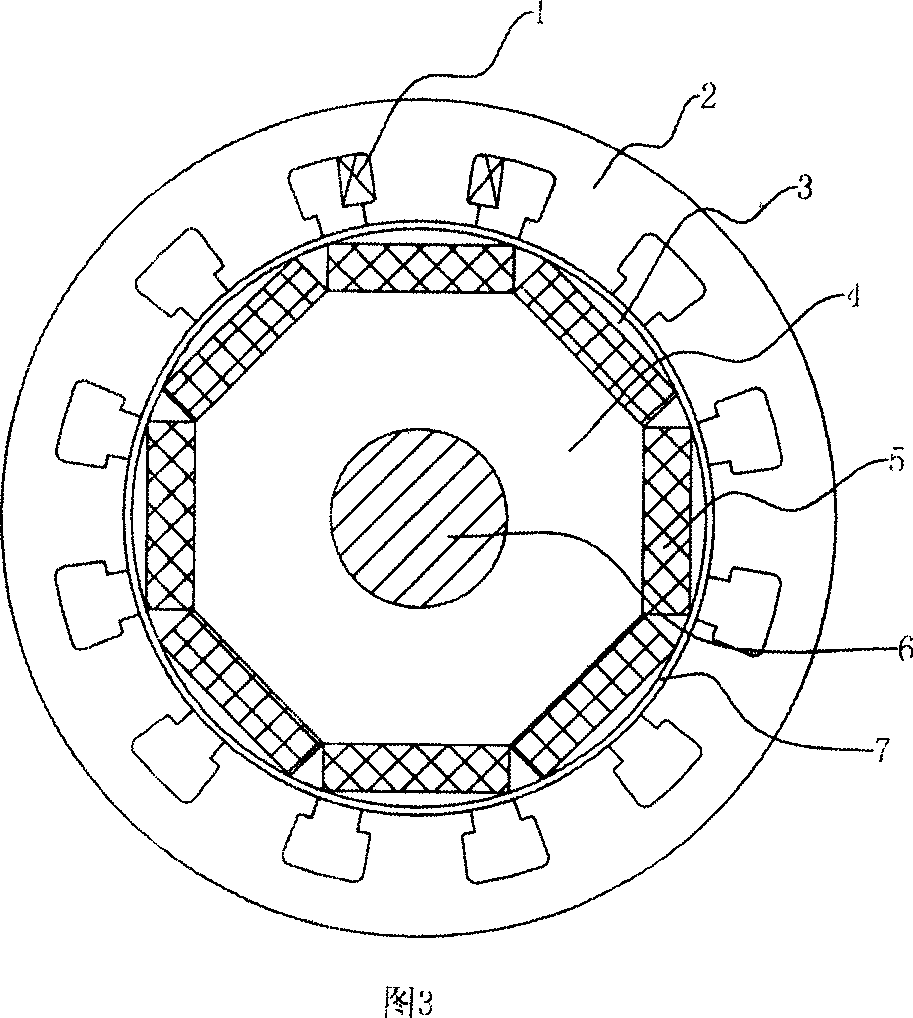

[0021] As shown in Figure 3, the stator and rotor poles of the motor body adopt a 3:2 tooth pole ratio and a geometric structure of bilateral salient poles. The stator 2 is made of silicon steel sheets, and the two symmetrical salient poles of the stator are equipped with concentrated excitation windings 1, which are connected in series to form a phase; the rotor is composed of a rotating shaft 6, a rotor core 4, a rectangular magnetic Steel 5, magnetic shoe 3 (guiding and protecting magnetic block) and magnetic isolation collar 7 form a cylinder; the rotor has a plurality of convex magnetic poles and is made of high-performance rare earth permanent magnet (NdFeB) material. The magnetic circuit structure is radial, and the magnetic isolation collar tightly fixes the magnetic shoes, permanent magnets, iron cores and structural parts of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com