Process of producing natural gas substitute with dimethyl ether as material

A technology for replacing natural gas and dimethyl ether, which is applied in the field of urban gas production, can solve problems such as affecting the interests of users, greatly reducing the calorific value of products, and limited usage, achieving obvious economic and social benefits, making up for the lack of strategic reserves, The effect of good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Dimethyl ether completely replaces liquefied petroleum gas to produce 10T natural gas

[0037] Take the production plant of Guangzhou Panyu Ganghua Gas Co., Ltd. as an example to illustrate.

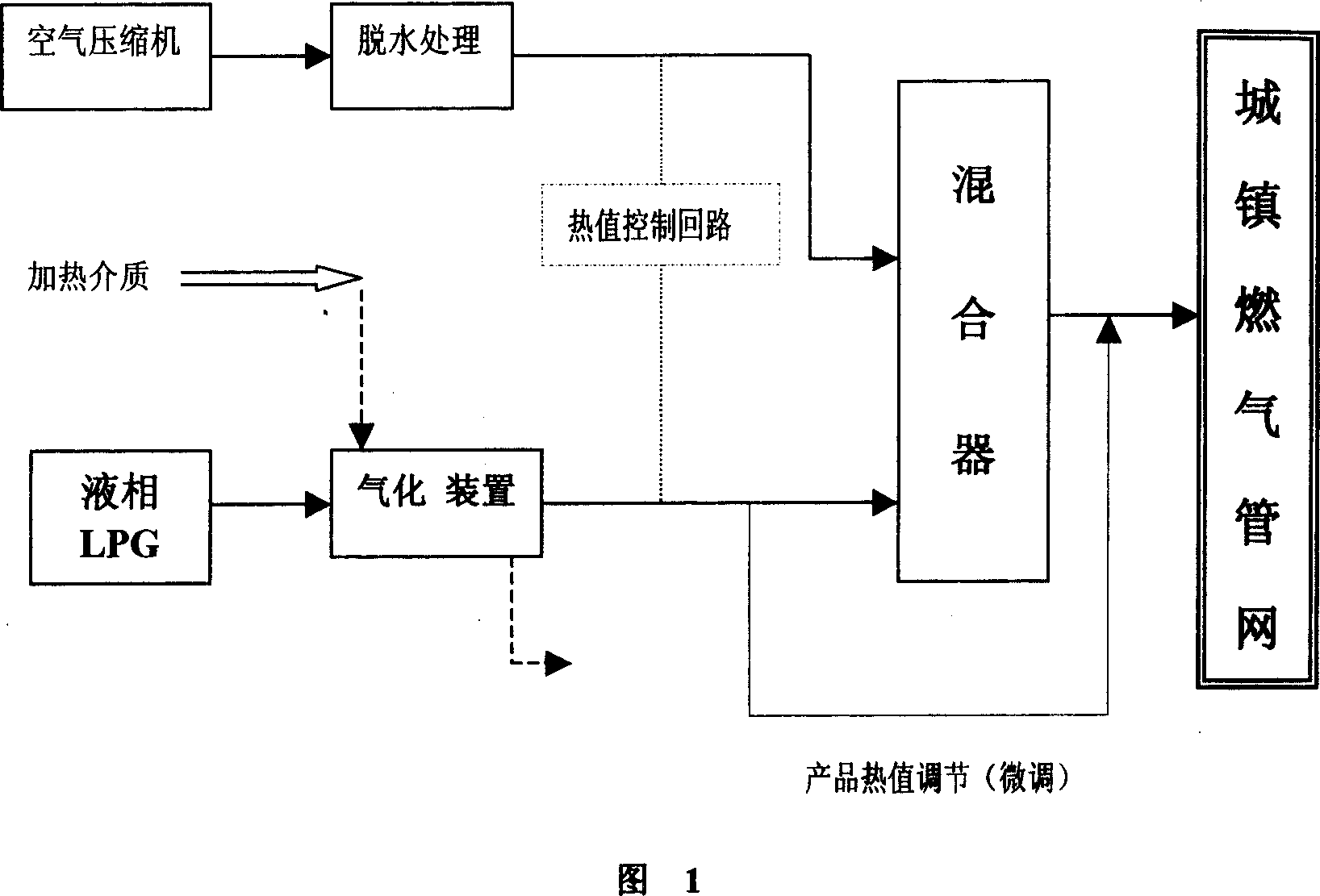

[0038] (1) The original device of Township China Gas Co., Ltd. is a production device for LPG mixed with AIR to produce 10T generation natural gas. The process flow chart of the original LPG mixed air production device is shown in Figure 1 (LPG mixed air production process flow chart for 10T generation natural gas) , using imported LPG as raw material, the typical composition of LPG is (gas phase volume): C 3 40%, C 4 60%, the relevant parameters are shown in Table 2 below.

[0039]

project

high calorific value

lower calorific value

High Wobbe Index

Burning potential

gas density

(kg / Nm 3 )

MJ / Nm 3 (kcal / Nm 3 )

parameters

(volume%)

40

60

...

Embodiment 2

[0057] Example 2. Partial substitution of dimethyl ether for liquefied petroleum gas to produce 10T natural gas (DME and LPG are stored separately in liquid phase and mixed after gasification)

[0058] Also take the production plant of Guangzhou Panyu Ganghua Gas Co., Ltd. as an example for illustration.

[0059] ①After partial replacement of raw materials, the process flow and description of "DME+LPG" mixed air to produce 10T generation natural gas

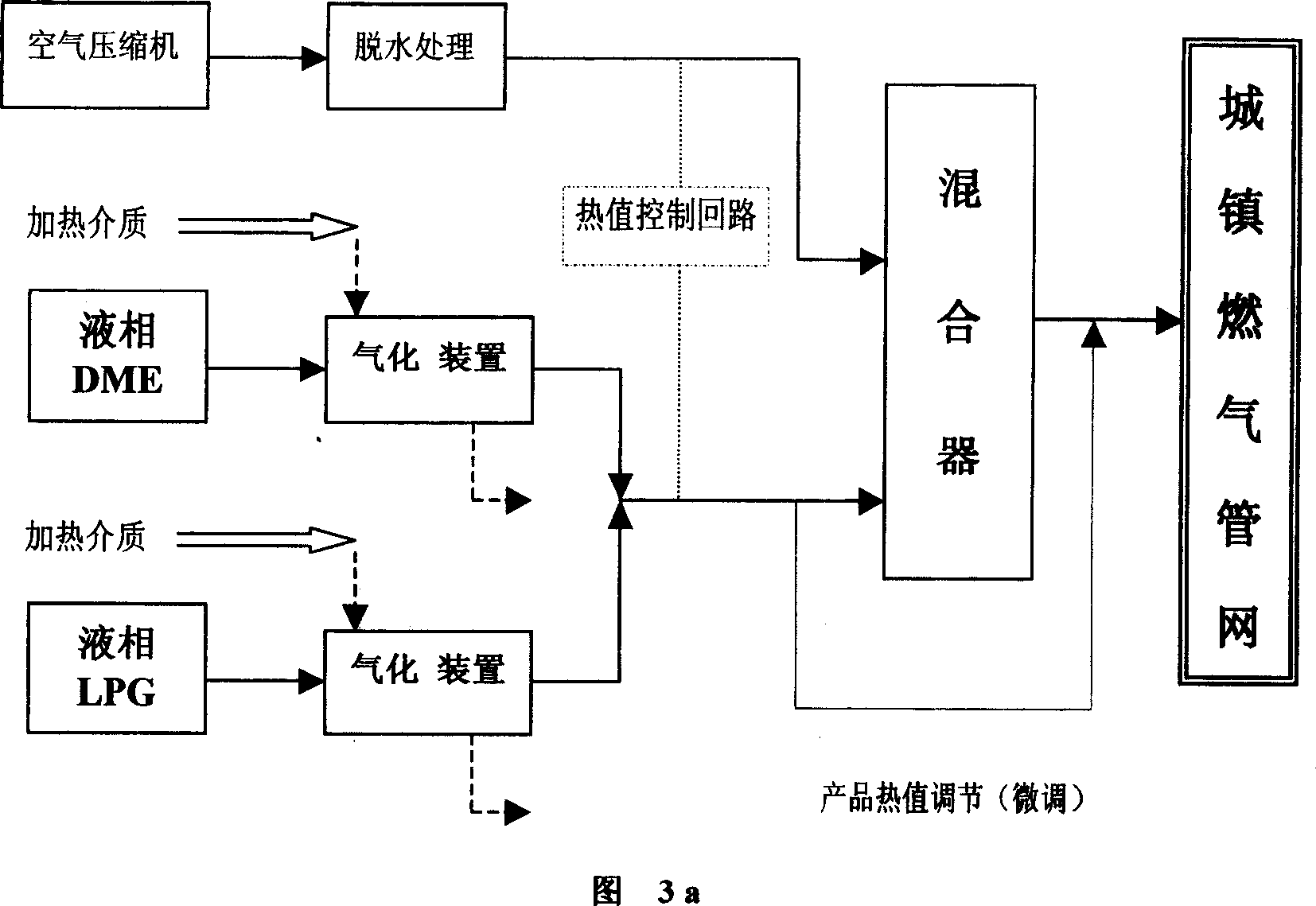

[0060] The process flow chart of producing 10T generation natural gas after partially replacing LPG with DME is shown in Figure 3a ("DME+LPG" mixed air production process flow chart of 10T generation natural gas).

[0061] DME and LPG stored in high-pressure storage tanks are pressurized by their respective liquid-phase hydrocarbon pumps, and then enter their respective gasification devices to exchange heat with heating media (hot water, steam, electric heating, etc.) to be gasified, and then, These two kinds of gas are mixed wi...

Embodiment 3

[0075] Example 3. Partial substitution of dimethyl ether for liquefied petroleum gas to produce 10T generation natural gas (DME and LPG liquid phase mixed storage, simultaneous gasification method)

[0076] It also takes the production equipment of Guangzhou Panyu Ganghua Gas Co., Ltd. as an example for illustration.

[0077] Except for the raw material storage part, the process flow of the production system is exactly the same as that of "dme and LPG liquid phase storage and mixing after gasification", and the product quality and safety performance indicators are exactly the same. Accompanying drawing 3b is the technological flow chart of producing 10T generation natural gas by DME partially replacing LPG (under liquid state, mixed storage) mixed with air.

[0078] The DME and LPG mixed raw material stored in the high-pressure storage tank is pressurized by the liquid-phase hydrocarbon pump and enters the gasification device to exchange heat with the heat source to be gasifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com