Degrading and viscosity reducing process for sewage containing oil and polymer

A technology for polymer and oily sewage, applied in the field of oilfield sewage treatment, can solve the problems of complex reactor, large amount of sludge, complex process, etc., and achieve the effects of simple reactor structure, small amount of sludge, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

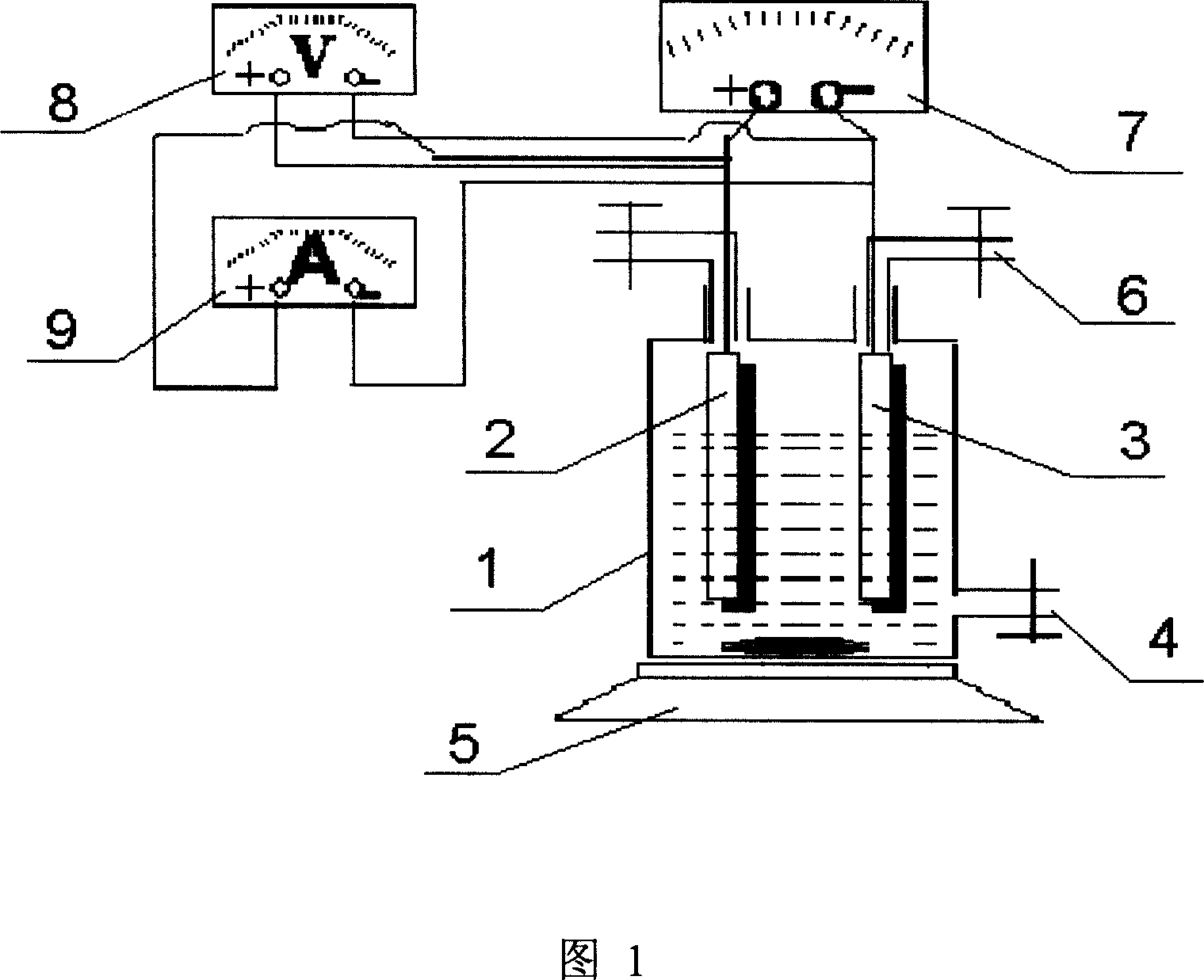

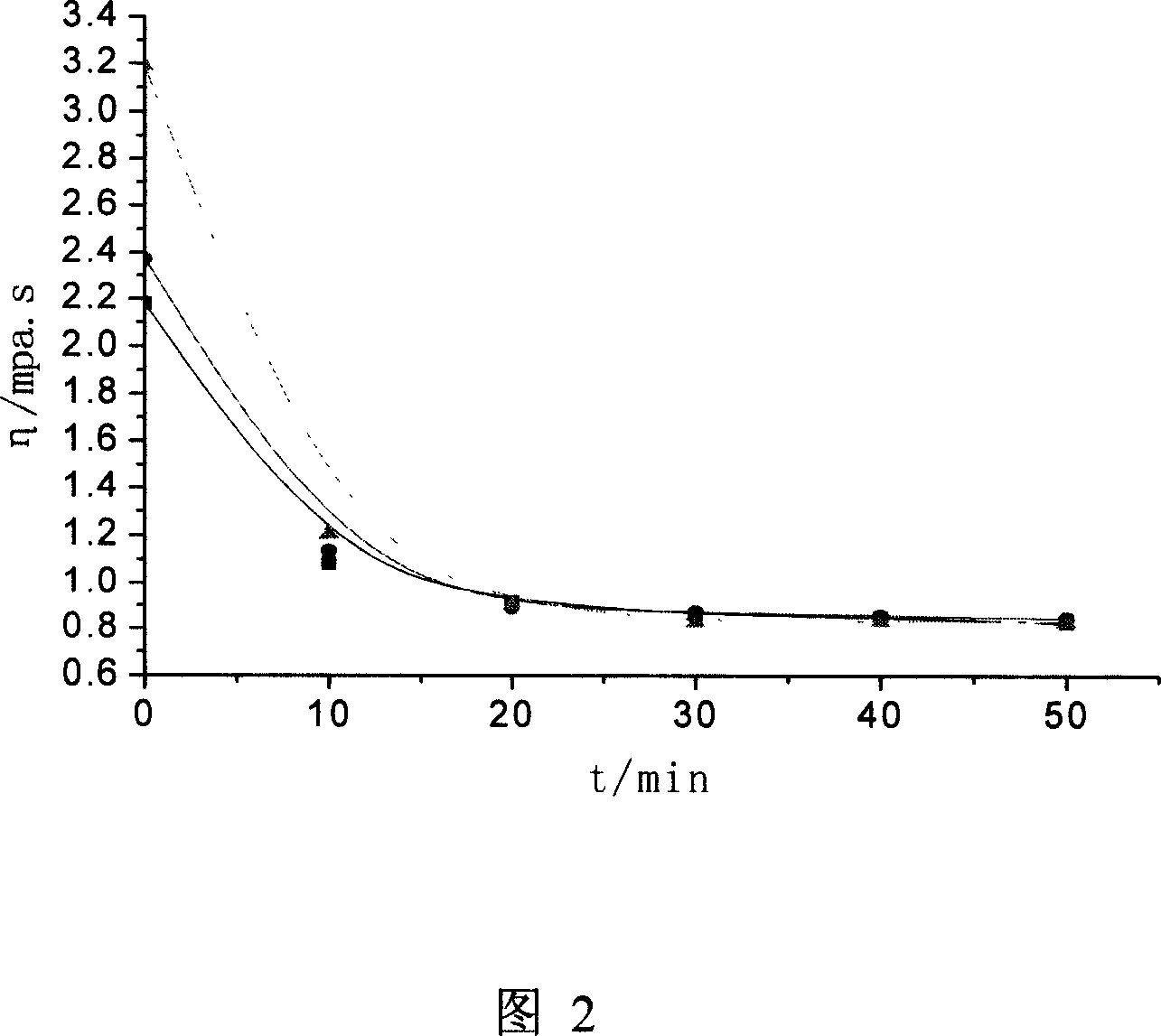

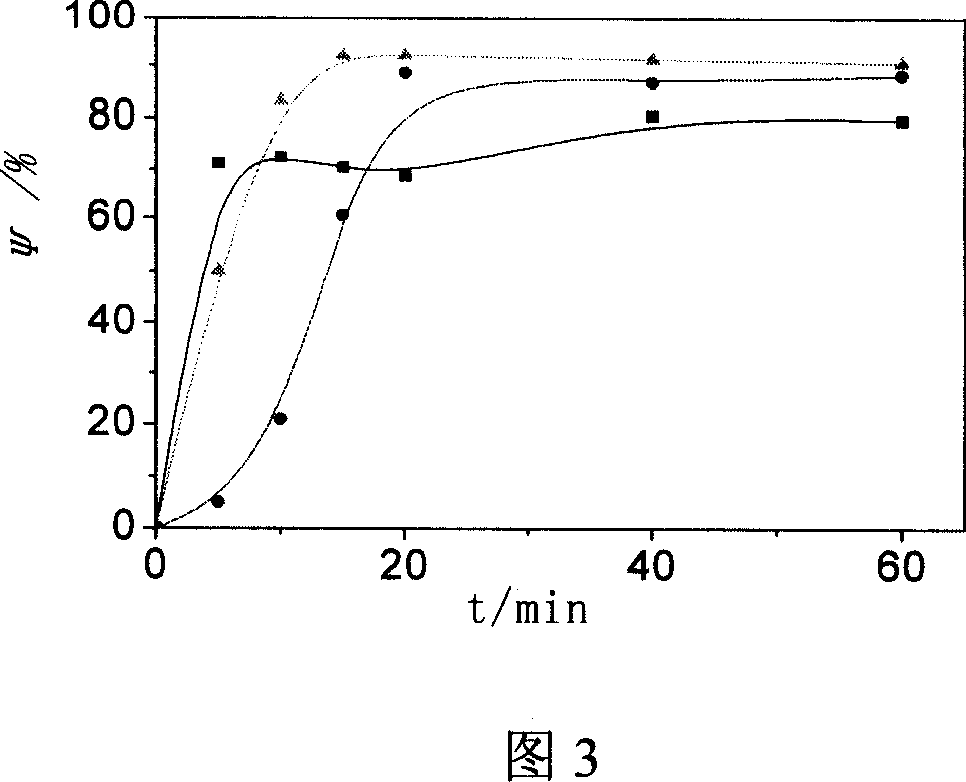

[0035] Specific embodiment one: the present invention is as follows to the step of oil field sewage treatment: one, the sewage that contains polymer is passed in the reactor 1 that anode 2, negative electrode 3 and agitator 5 are housed, two, agitator 5 is in Slow stirring, under the condition of normal temperature, the acidic medium in the reactor 1, the cell voltage of 10-30V, 75-80mA / cm 2 The current density is treated under the action of anode 2 and cathode 3 for 20min to 50min. It can realize the viscosity reduction of sewage and the degradation of organic pollutants and emulsified oil, and can meet the requirements of reinjection water and discharge water quality after being filtered by quartz sand.

specific Embodiment approach 2

[0036] Embodiment 2: The acidic medium in step 2 of this embodiment is HCl, and its pH=1-6, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0037] Specific embodiment three: In this embodiment, an additive is added in step two, and the additive is NaCl or CaCl 2 , the others are the same as those in Embodiment 1.

[0038] Additives contain a lot of Cl - , with Cl on anode 2 2 Precipitated, and Cl 2 It is beneficial to the degradation of organic matter and has a bactericidal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com