High-frequency high voice and strong sound wave blower

A technology of soot blower and strong sound wave, which is applied in the direction of sound-producing equipment, instruments, and treatment of combustion products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

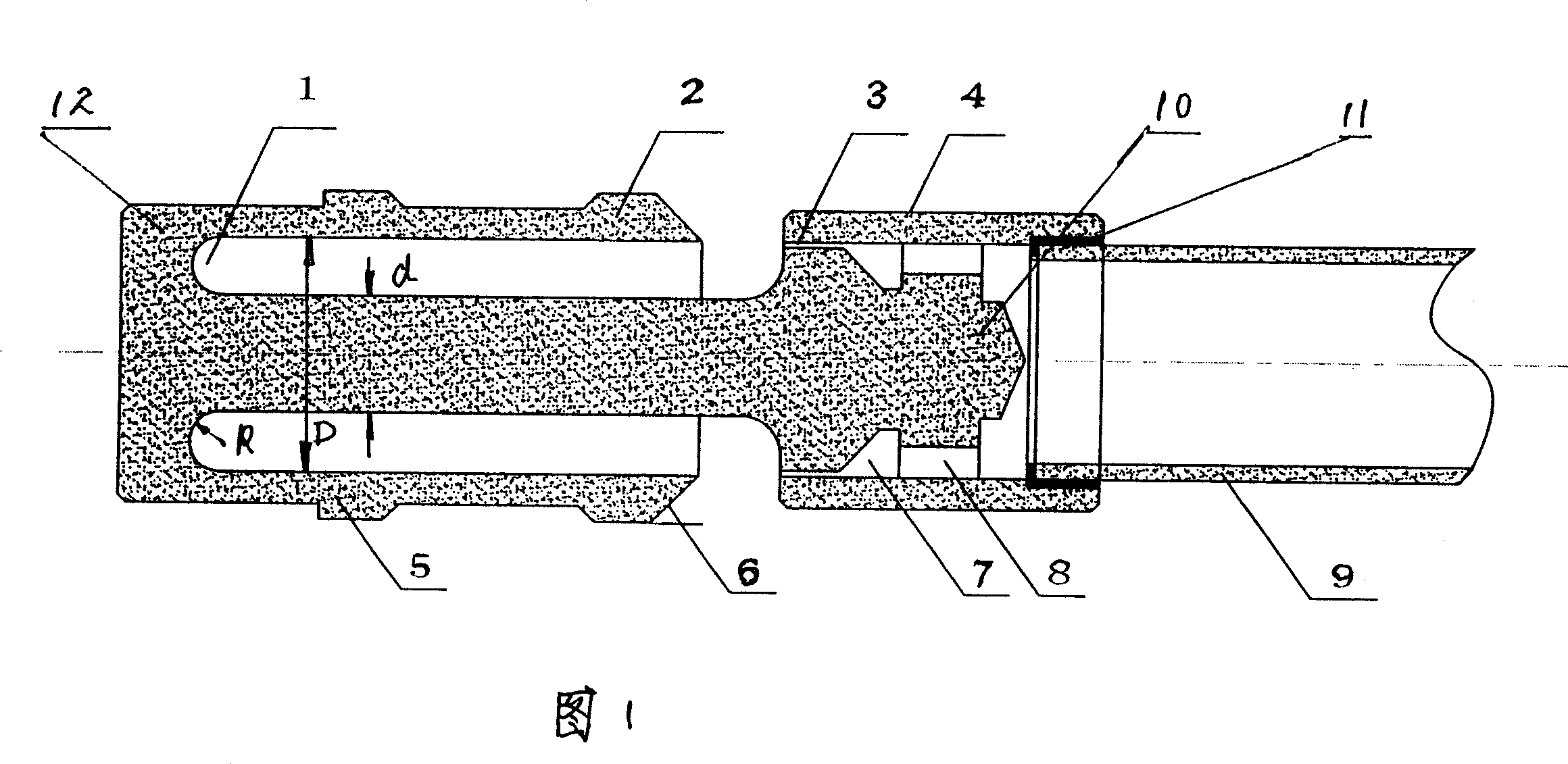

[0009] The structure schematic diagram of the high-frequency high-sound intensity sootblower proposed by the present invention is shown in FIG. The resonant cavity cap 12, the airflow ring cover 4 and the air guide tube 9 are installed coaxially in sequence. The outer wall of the resonant cavity cap 12 is provided with a resonant cavity rectifying ring 5, the end of the resonant cavity cap is a turbulent flow ring 2, and the included angle α between the resonant wedge 6 at the end of the turbulent flow ring 2 and the extension line of the outer wall of the turbulent flow ring is 25°~ 70°. The center of the resonant cavity cap 12 is a support concentric rod 10, and an annular resonant cavity 1 is formed between the root of the support concentric rod 10 and the inner wall of the resonant cavity cap. One end of the airflow ring cover 4 and the inner wall of the airflow ring cover 4 form an annular gap 3 , an air chamber 7 and a guide hole 8 in sequence. The end of the guide tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com