Non-load-bearing lightgage steel joist isolation wall and its construction method

A technology of light steel keel and construction method, applied in the direction of walls, building components, buildings, etc., can solve the problems of earthquake resistance, fire prevention, waterproof, sound insulation, heat insulation, etc., and achieve simple construction methods, saving construction funds, and reducing decoration. link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

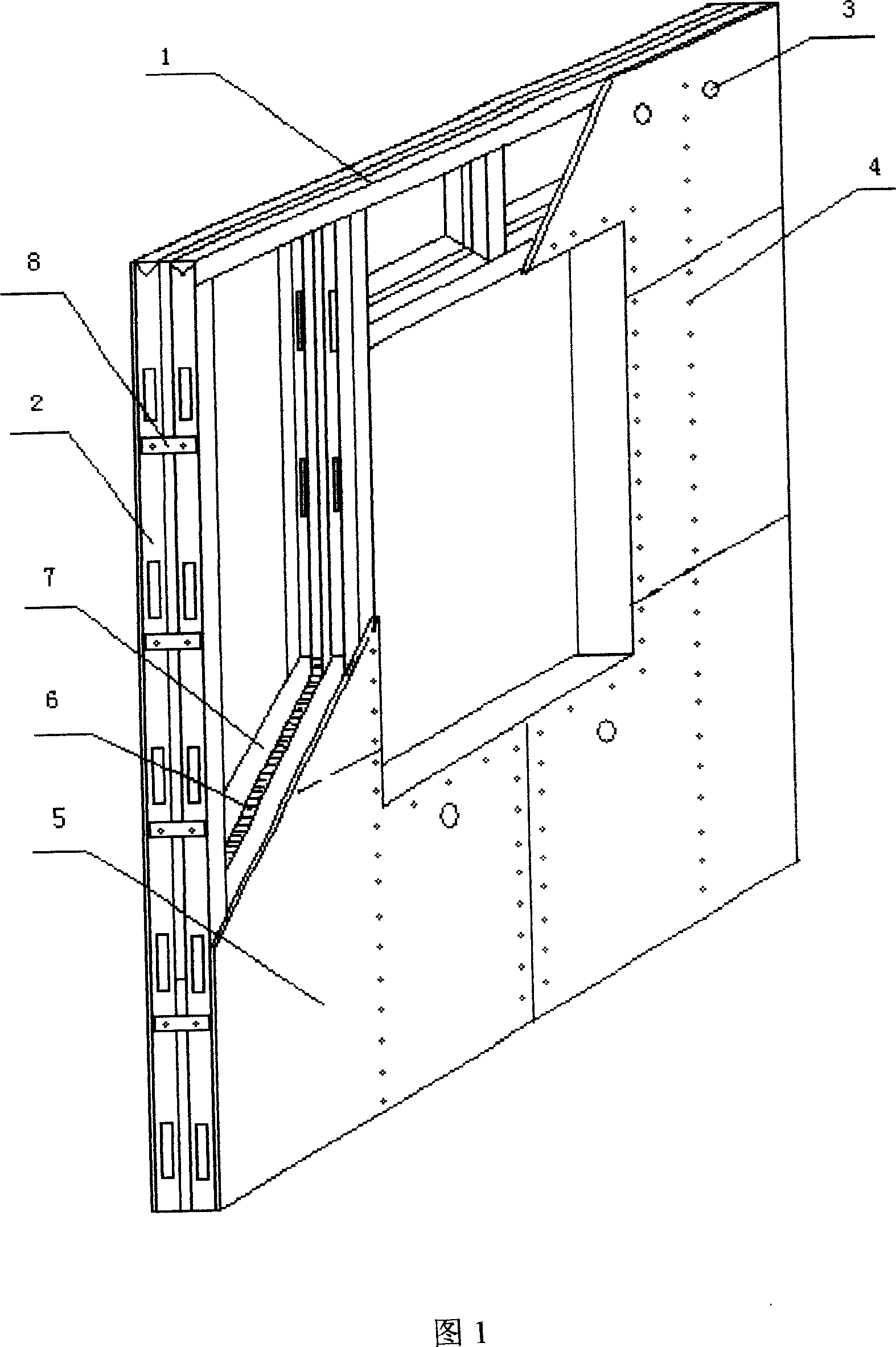

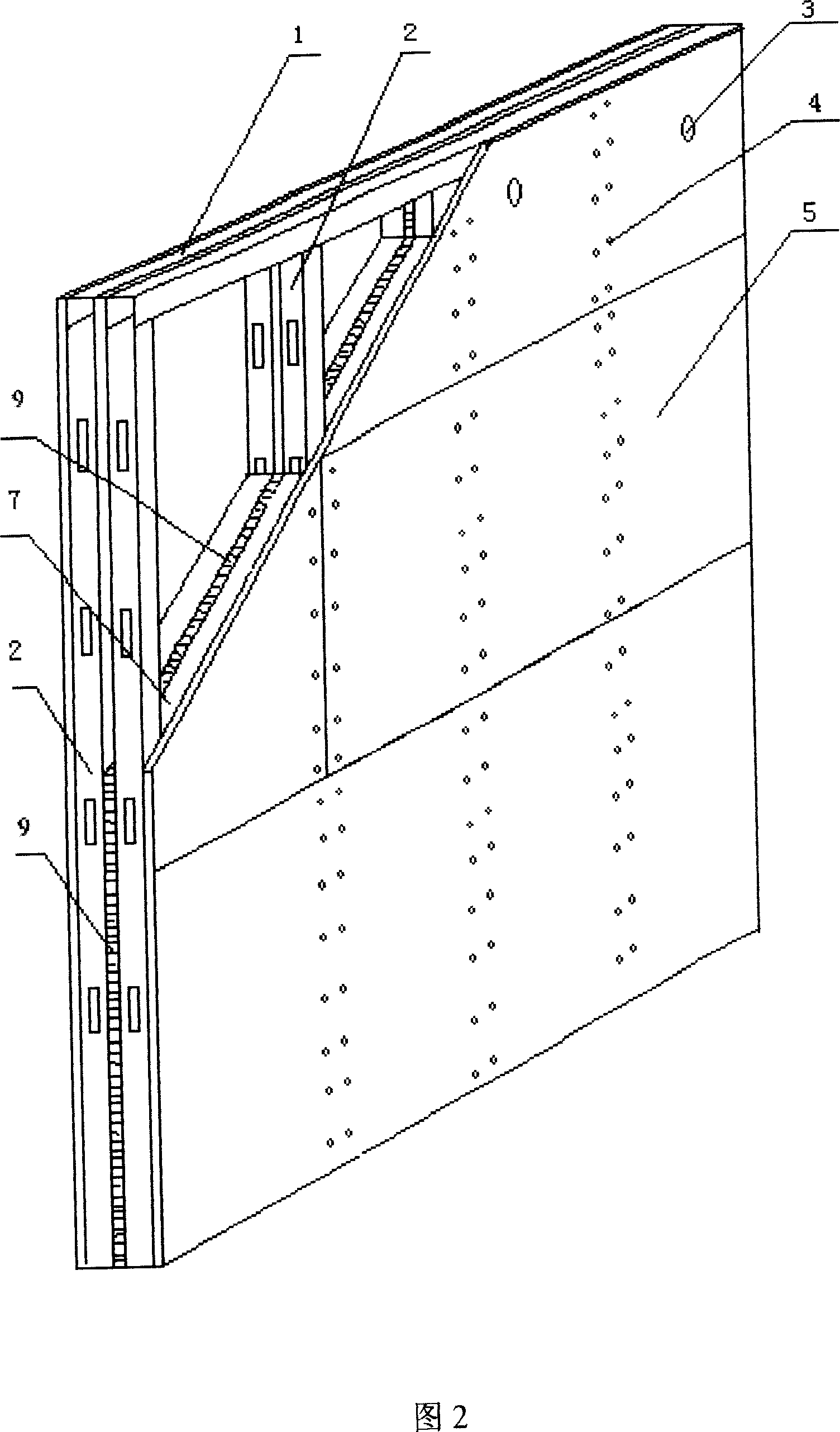

[0048] A non-load-bearing light steel keel insulation exterior wall used in the main building of a home furnishing expo center in Guangzhou

[0049] The non-load-bearing light steel keel insulation exterior wall shown in Figure 1 includes the light steel keel skeleton buried in the poured lightweight mixed mortar 7, and the panels 5 installed on both sides of the light steel keel, and the light mixed mortar 7 and The light steel keel frame is integrally formed similar to the reinforced concrete matrix structure. Self-tapping screw connectors 4 are provided between the panel 5 and the keel. The grouting holes 3 are preset on the panel 5. The light steel keel frame and the steel structure or frame structure of the building There are also connectors between the ground, beams and columns of the building. The panel 5 is a medium density cement fiber board, and the lightweight mixed mortar 7 is a lightweight mixed mortar including cement, sand and polymer emulsion.

[0050] The lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com