Driving device for automobile container loading and unloading

A technology of a drive device and a cargo box, which is applied to vehicles with loading ramps, vehicles with inclined bearing motion, etc., can solve the problems of poor control of motion synchronization, affecting traction efficiency, and high manufacturing costs, and achieves simple and simplified structure. Structure, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

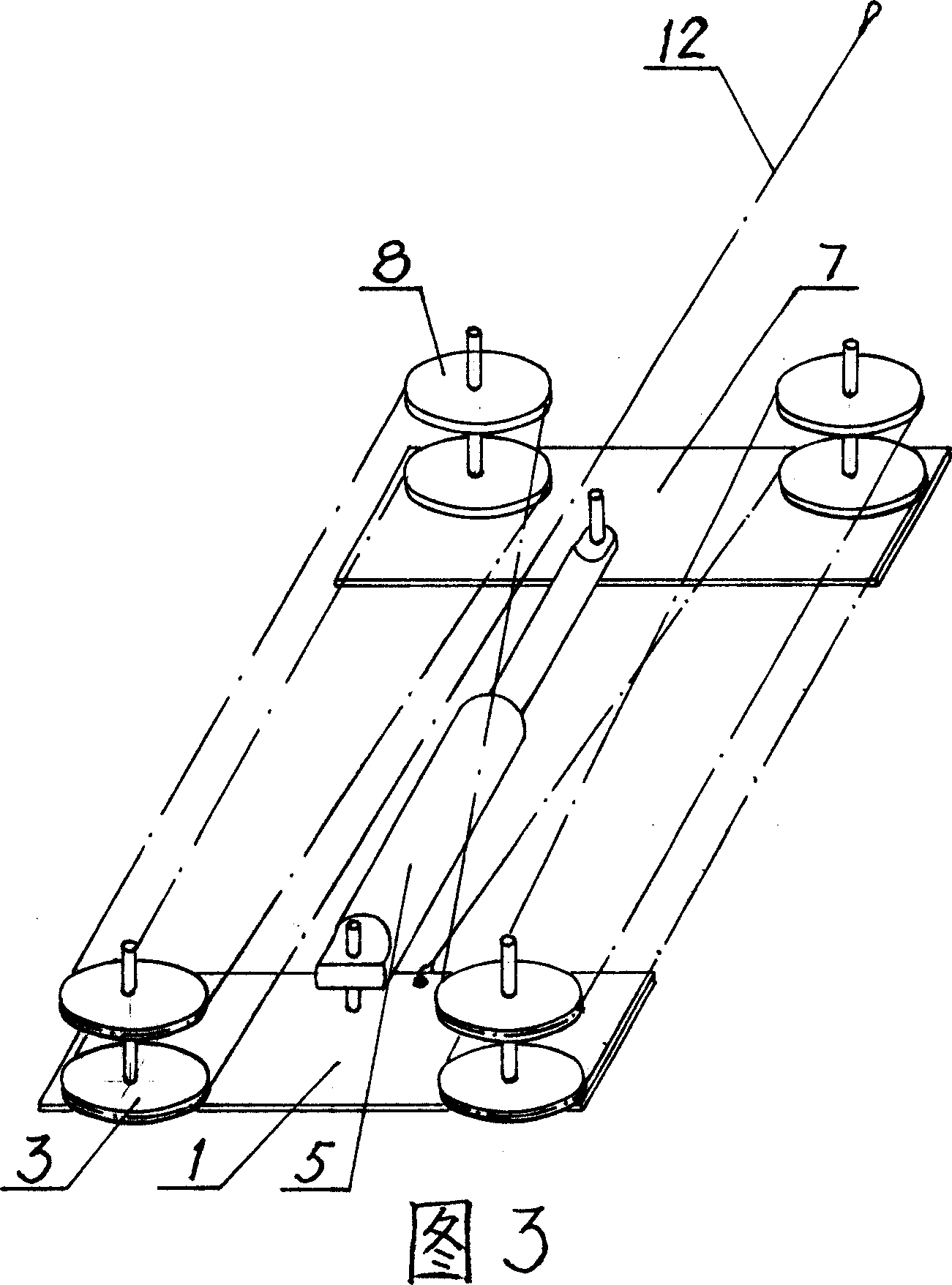

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] As shown in Fig. 1 and Fig. 2, the subframe 1 is frame-shaped, and the hinge seat 4 connected with the automobile chassis and the hinge shaft 6 connected with the automobile lifting cylinder are installed on both sides of the frame-shaped subframe. Several idler rollers 2 for supporting the cargo box are also installed on both sides of the vehicle frame. The front end of auxiliary frame is equipped with the traction main fixed pulley 10 of container. The rear end of the auxiliary frame is equipped with a fixed seat 11, and two rotating shafts are vertically installed side by side on the fixed seat, and two guide fixed pulleys 3 are respectively installed on the two rotating shafts, and the rear end fixed seat 11 of the auxiliary frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com