Sartorius with thread-cutting device

A sewing machine and thread cutting technology, which is applied in the field of sewing machines, can solve problems such as the inefficiency of sewing operability, difficult handling of sewing fabrics, and the need for a lot of effort in assembly, so as to achieve sewing operability, lighten assembly operations, and construct The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

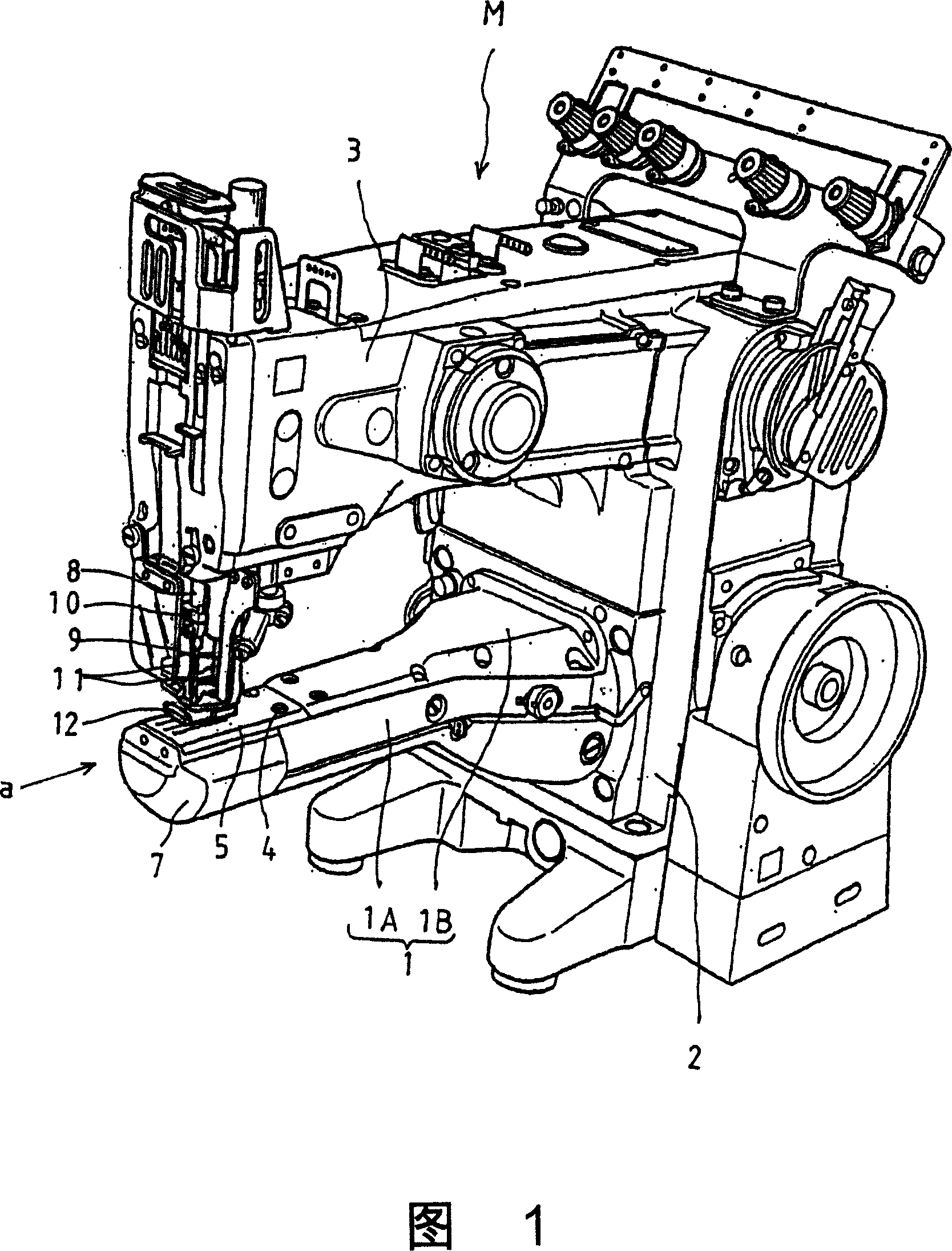

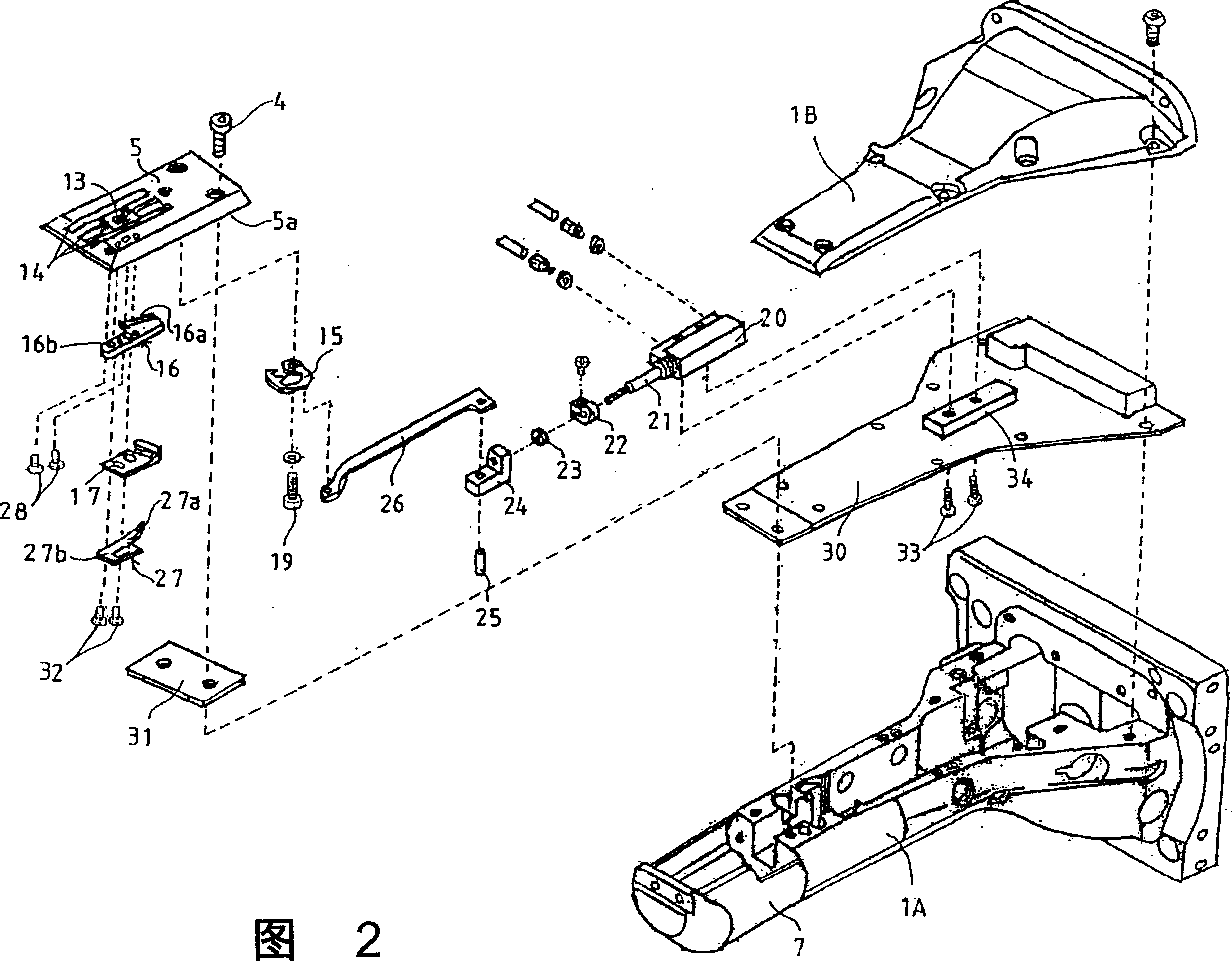

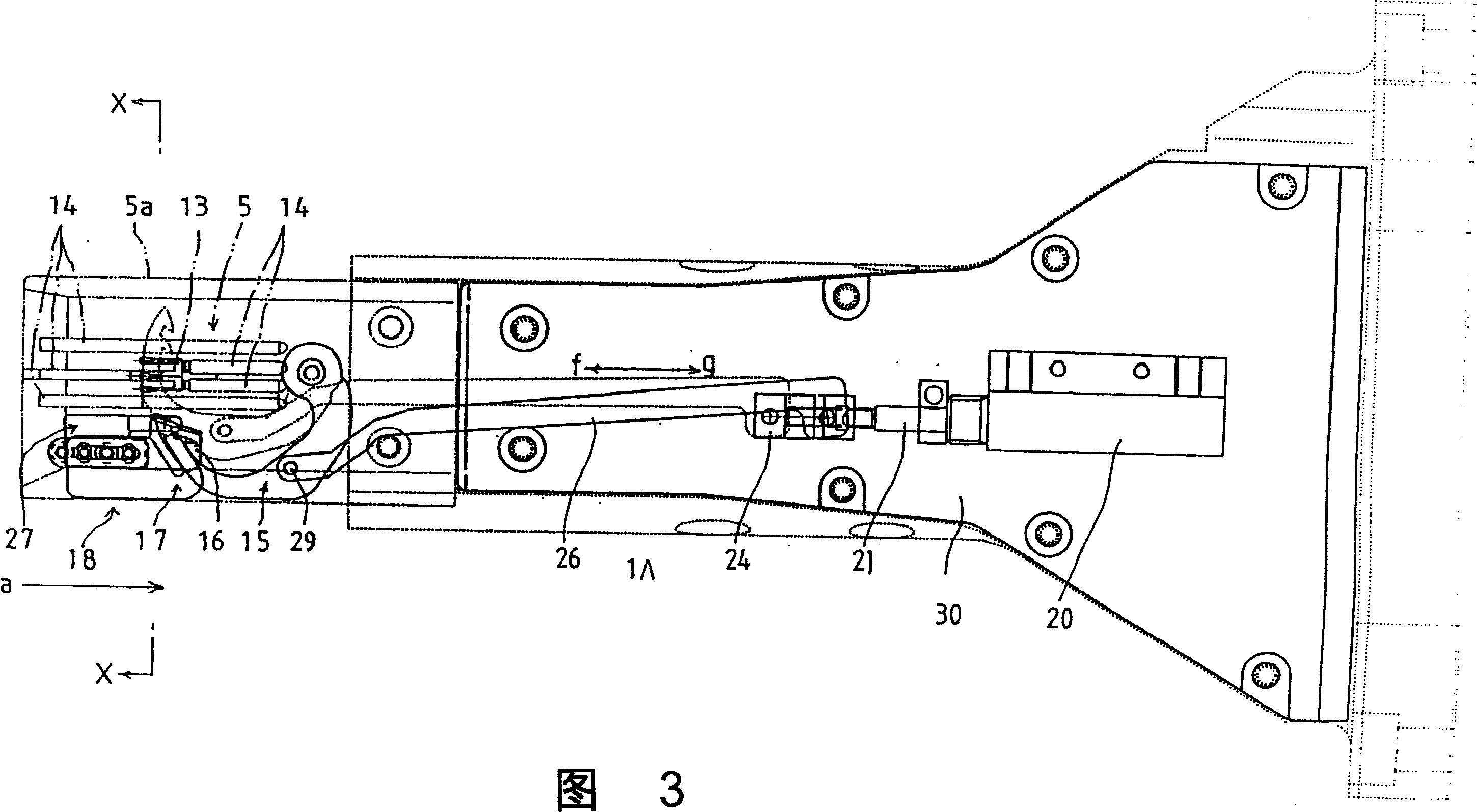

[0018] Fig. 1 is a schematic perspective view of the whole of a three-needle cylinder sewing machine with a thread cutting device according to the present invention, Fig. 2 is an exploded perspective view of the constituent parts of the thread cutting device, and Fig. 3 is a thread cutting device with a part of the sewing machine cross-cut to serve as the main part Near the top view of the center, Fig. 4(A) is an enlarged longitudinal sectional view along the X-X line of Fig. 3, and Fig. 4(B) is an enlarged view of part B of Fig. 4(A). In this three-needle cylinder sewing machine M, a sewing machine main shaft, a needle drive mechanism, and a presser foot drive mechanism are provided extending forward from the lower portion of the sewing machine base (sewing machine body) 2 (since these components are known, so The detailed structure and description thereof are omitted) of the sewing machine arm 3 and the cylindrical seat 1.

[0019] As shown in FIG. 2, the cylindrical seat 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com