Cooling device and cooling method of solvent method cellulose fiber spinning

A cellulose fiber and cooling device technology, applied in fiber treatment, textile and papermaking, artificial filament physical therapy, etc., can solve the problems of complex device, uneven blowing, difficult operation, etc., and achieve simple structure, good cooling effect, Smooth spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

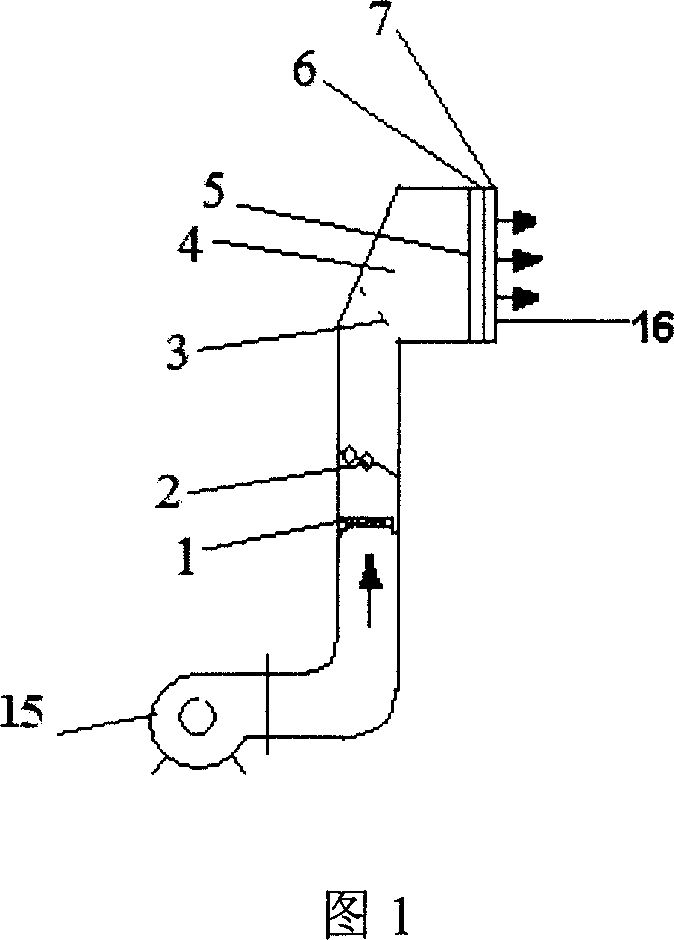

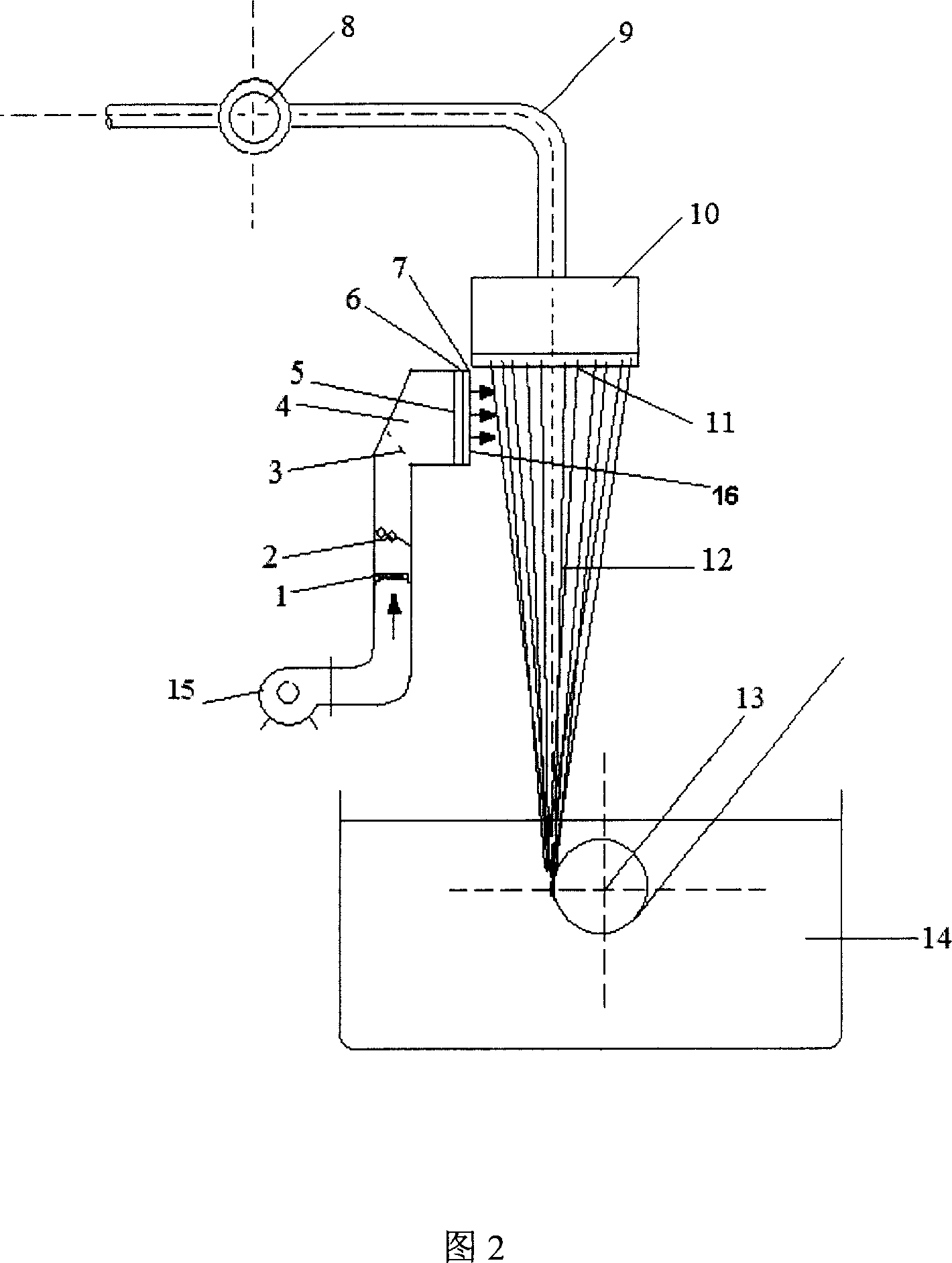

[0024] See Fig. 1, a cooling device is installed below the spinneret 11 of the spinneret 11 of the solvent method cellulose fiber spinning equipment spinneret assembly 10, which is a fan 15, air temperature regulator 1, control valve 2, porous plate A3 , a blowing device composed of a plenum 4, a perforated plate B5, a wire mesh layer 6, a rectifying plate 7 and an air outlet 16. The width of the blowing port 16 is 200 mm, and the height is 130 mm. The upper edge of the blowing port 16 is in the same plane as the face of the spinneret 11 of the spinning device, that is, the vertical distance between the two is 0. The horizontal distance between the vertical surface of the blowing port 16 and the centerline of the spinneret assembly 10 is 200mm. The cellulose raw material with a degree of polymerization (DP) of 600 was dissolved in an NMMO aqueous solution with a cellulose content of 10%, and the resulting cellulose spinning solution had a refractive index of 1.4860, a temperat...

Embodiment 2

[0028] A cooling device identical to embodiment 1 is installed below the spinneret 11 faces of the spinneret assembly 10 of the solvent method cellulose fiber spinning equipment, but the width of the tuyere is 250mm, and the height is 100mm. The vertical distance between the 11 surfaces is 4 mm, and the horizontal distance between the blowing port surface and the center line of the spinneret 10 is 150 mm. Using cellulose with a degree of polymerization (DP) of 700 and NMMO aqueous solution as raw materials, a spinning solution with a cellulose content of 13% is prepared. The refractive index of the solution is 1.4870, the temperature is 99 ° C, the viscosity is 1200 Pa s, brown transparent. After being pressurized by the booster pump, it passes through the melt filter, enters the spinning metering pump 8, and enters the spinneret assembly 10 through the conduit 9, from the spinneret with a diameter of 0.075mm and a number of 6000 holes. 11 squirts. The cold air blows and coo...

Embodiment 3

[0030]A cooling device identical to that of Embodiment 1 is installed below the spinneret 11 face of the spinneret assembly 10 of the solvent-process cellulose fiber spinning equipment, but the width of the blowing port is 280 mm, and the height is 90 mm. The upper edge of the blowing port and the spinneret The vertical distance between the 11 surfaces is 2 mm, and the horizontal distance between the surface of the blowing port and the centerline of the spinneret assembly 10 is 180 mm. Use cellulose with a degree of polymerization (DP) of 700 and an aqueous NMMO solution as raw materials to prepare a spinning solution with a cellulose concentration of 9%, so that the solution has a refractive index of 1.4850, a temperature of 92°C, and a brown color with a viscosity of 1200 Pa·s. transparent body. After being pressurized by the booster pump, after passing through the melt filter, it enters the spinning metering pump 8, and enters the spinneret assembly 10 through the conduit 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com