Activation molded coal adhesive, preparation method and application thereof

A binder and activated technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of increasing investment and briquette production cost, complex binder adding process, difficult large-scale industrial production, etc., to achieve The effect of remarkable sulfur fixation efficiency, simple and easy-to-control adding process, and easy promotion and popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

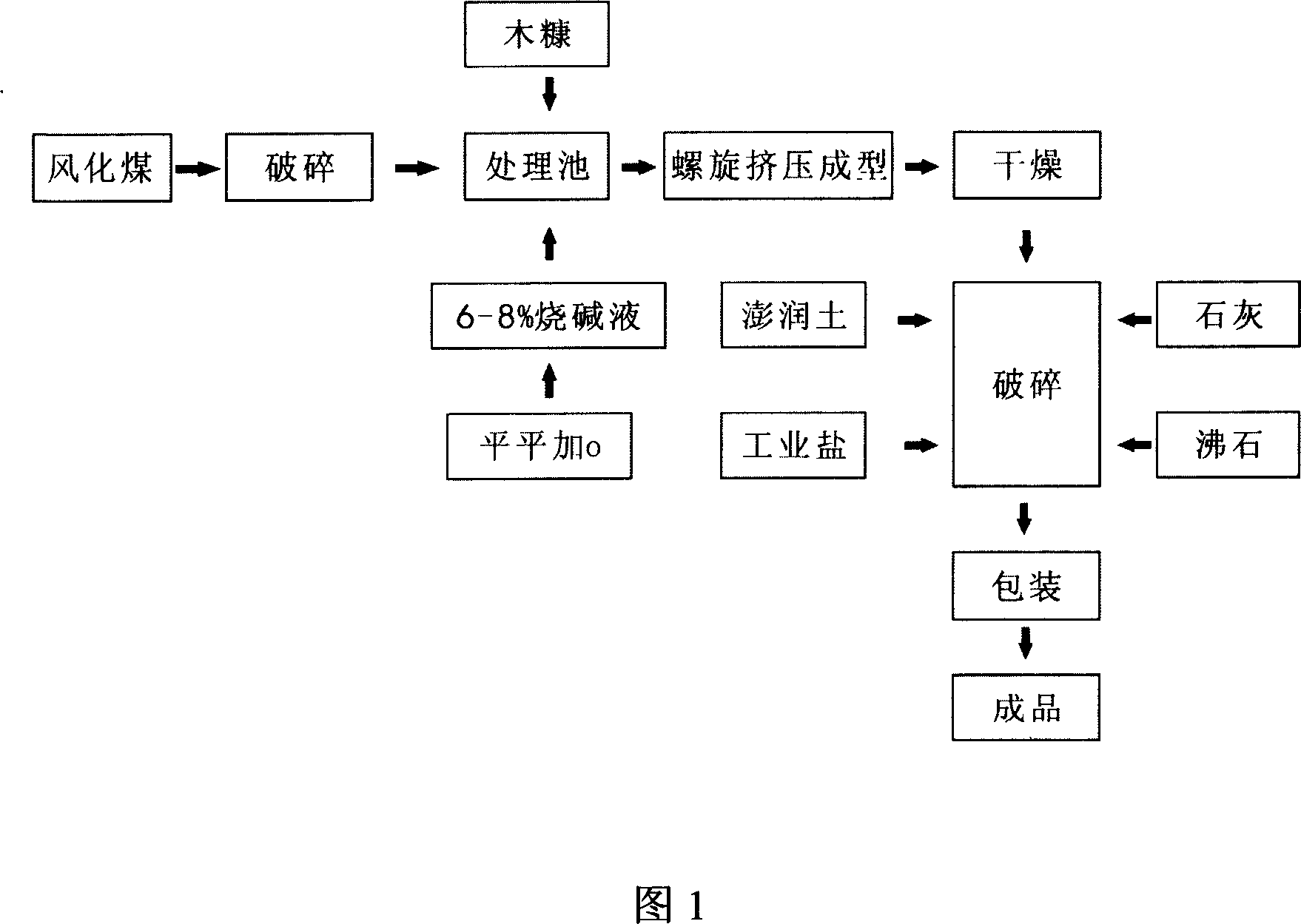

Embodiment 1

[0042] Activated briquette binder, by weight percentage, comprises the following components:

[0043] Alkaline treated wood bran 21%

[0044] Sodium Humate 39%

[0045] Bentonite 26%

[0046] Lime 9%

[0047] Zeolite 2.5%

[0048] Industrial salt 2.5%.

Embodiment 2

[0050] Activated briquette binder, by weight percentage, comprises the following components:

[0051] Alkaline treated wood bran 20%

[0052] Sodium Humate 38%

[0053] Bentonite 27%

[0054] Lime 10%

[0055] Zeolite 2.5%

[0056] Industrial salt 2.5%.

Embodiment 3

[0058] Activated briquette binder, by weight percentage, comprises the following components:

[0059] Alkaline treated wood bran 22%

[0060] Sodium Humate 40%

[0061] Bentonite 26%

[0062] Lime 9%

[0063] Zeolite 1.5%

[0064] Industrial salt 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com