Tunnel type optical wave roasting furnace

A tunnel-type roaster technology, applied in the field of tunnel-type light-wave roaster, can solve the problems of not being able to adapt to the construction of a conservation-oriented society, the service life is only 270 times, and the quartz stone is not easy to burn through, so as to improve energy utilization and reduce labor costs. and power consumption, reducing the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

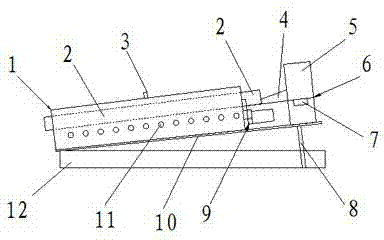

[0018] like figure 1 As shown, the tunnel-type light-wave roasting furnace is composed of an ultrasonic feeder 6 , a roasting box 1 , a rotating device 9 , a quartz tunnel tube 2 , a temperature sensor 3 , a carbon fiber light-wave tube 11 , and an adjustable bracket 12 . There is a support frame 10 on the top of the adjustable support 12, and an adjustment rod 8 is arranged at one end;

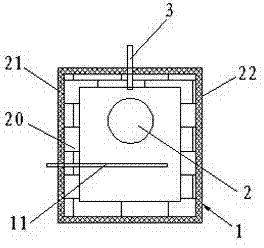

[0019] like figure 1 , 3 As shown, the roasting box 1 is in the shape of a cuboid, and is fixedly installed on the support frame 10 of the adjustable bracket 12 matching it; the inside of the roasting box 1 is surrounded by refractory bricks 20, and the surroundings of the firebricks 20 are asbestos heat insulation layers 21 , The outer periphery of the asbestos heat insulation layer 21 is a metal plate 22 .

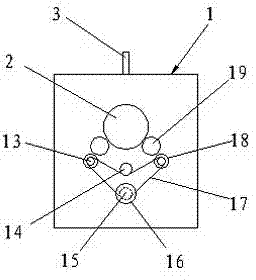

[0020] like figure 1 , 2 , Shown in 3, the quartz tunnel tube 2 is horizontally installed in the roasting box 1, and the two tube heads of the quartz tunnel tube 2 stretch out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com