Synthesis method of zirconium tungstate with minus thermal-expansion coefficient

A technology with a negative thermal expansion coefficient and a synthesis method, which is applied to tungsten compounds, zirconium compounds, chemical instruments and methods, etc., can solve problems such as chemical ratio mismatch, achieve low cost, and avoid exhaust gas pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

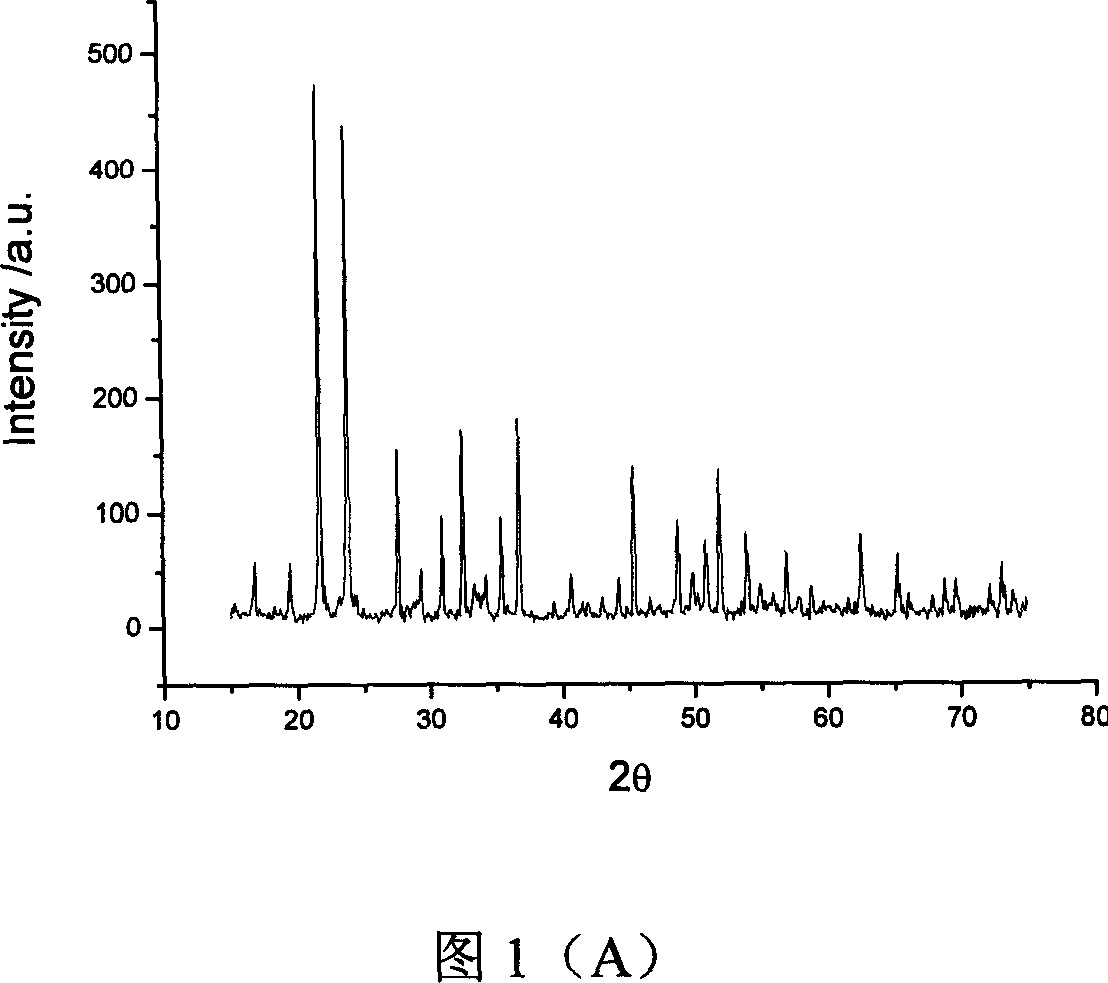

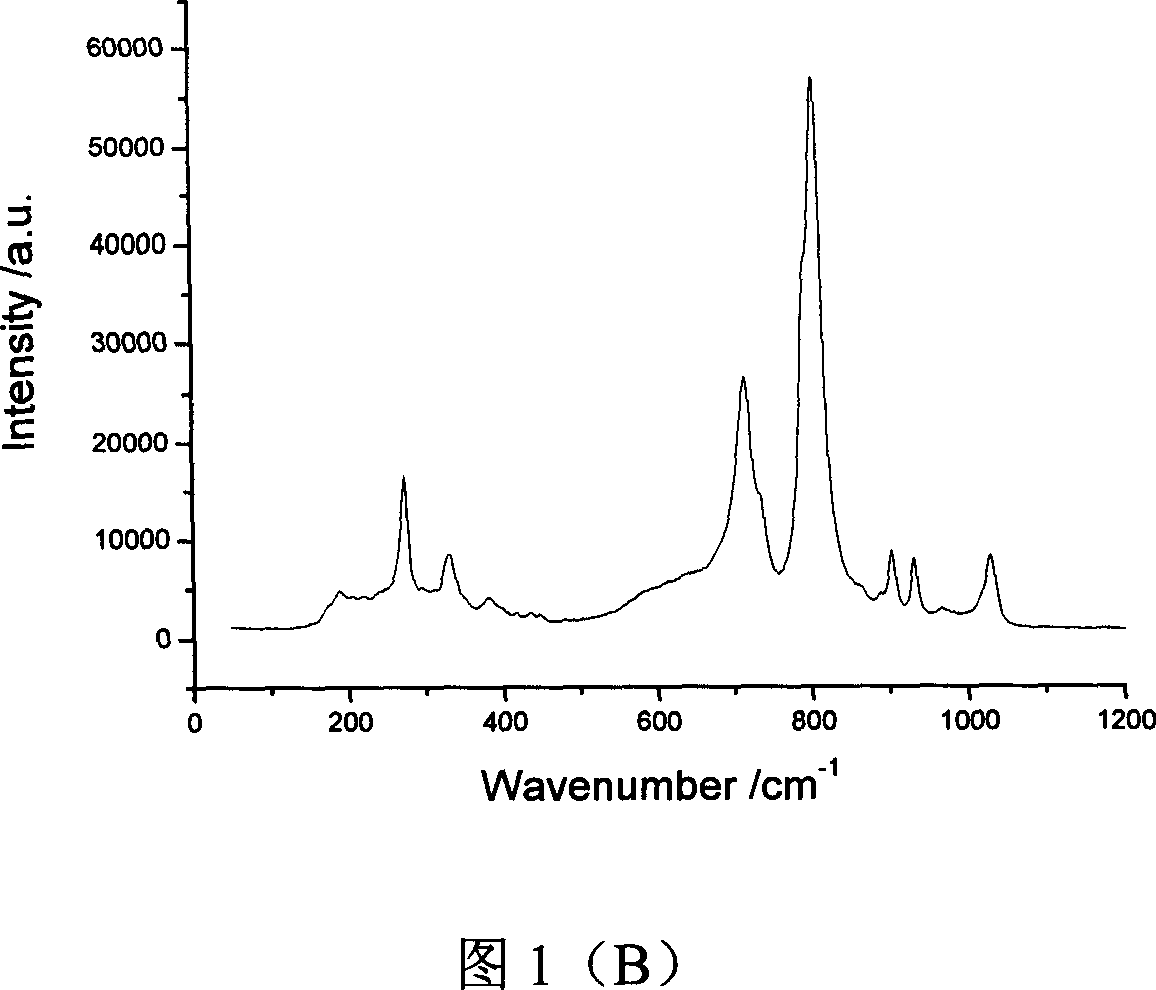

[0021] Example 1, rapid sintering and synthesis of negative thermal expansion coefficient material ZrW 2 o 8 .

[0022] Weigh ZrO at a molar ratio of 1:2.2 2 with WO 3 , mixed and ground for 90 minutes, the mixture was compacted, and then sintered and synthesized in a high-temperature furnace. The synthesis process parameters are: ECFK-10-14 high-temperature sintering furnace produced by Shanghai Guangyi High-temperature Technology Industry Co., Ltd., the sintering temperature is 1450° C., and the sintering time is 5 minutes. After sintering, put it into water to cool quickly. Composite material appears as a uniform green mass. XRD and Raman spectroscopy tests show that the synthetic material is α-phase zirconium tungstate, that is, α-phase ZrW 2 o 8 . The corresponding XRD and Raman spectra are shown in Figure 1(A) and Figure 1(B).

[0023] XRD analysis by and 、 , "Search-Match" and other XRD database comparisons are completed (the same below). X-ray Diffraction P...

Embodiment 2

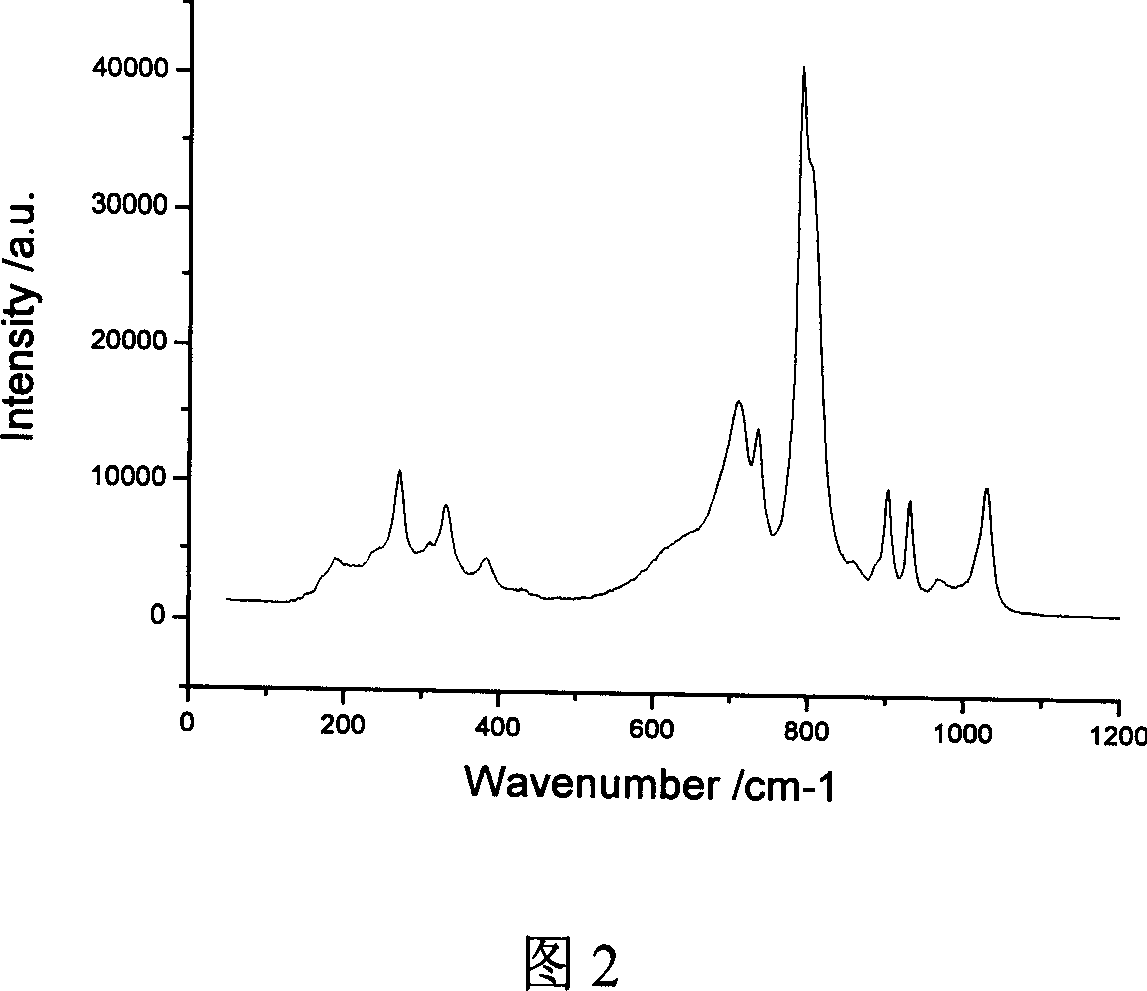

[0026] Example 2, rapid sintering and synthesis of negative thermal expansion coefficient material ZrW 2 o 8 .

[0027] Weigh ZrO at a molar ratio of 1:2.2 2 with WO 3 , mixed and ground for 90 minutes, the mixture was compacted, and then sintered and synthesized in a high-temperature furnace. The synthesis process parameters are: ECFK-10-14 high-temperature sintering furnace produced by Shanghai Guangyi High-temperature Technology Industry Co., Ltd., the sintering temperature is 1450 ° C, and the sintering time is 7 minutes. After sintering, put it into water to cool quickly. Composite material appears as a uniform green mass. XRD and Raman spectroscopy tests show that the synthetic material is α-phase zirconium tungstate, that is, α-phase ZrW 2 o 8 . The corresponding XRD and Raman spectra are shown in Figure 2(A) and Figure 2(B).

Embodiment 3

[0028] Example 3: rapid sintering and synthesis of negative thermal expansion coefficient material ZrW 2 o 8 .

[0029] Weigh ZrO at a molar ratio of 1:2.2 2 with WO 3 , mixed and ground for 90 minutes, the mixture was compacted, and then sintered and synthesized in a high-temperature furnace. The synthesis process parameters are: ECFK-10-14 high-temperature sintering furnace produced by Shanghai Guangyi High-temperature Technology Industry Co., Ltd., the sintering temperature is 1400 ° C, and the sintering time is 10 minutes. After sintering, put it into water to cool quickly. Composite material appears as a uniform green mass. XRD and Raman spectroscopy tests show that the synthetic material is α-phase zirconium tungstate, that is, α-phase ZrW 2 o 8 . The corresponding XRD and Raman spectra are shown in Figure 3(A) and Figure 3(B).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com