Cap rotating mechanism for continuous round disc type cap rotating machine

A capping machine, a disc-type technology, applied in the direction of screw caps, etc., can solve problems such as over-tightening of the cap, scratches on the surface of the cap, and insufficient screwing of the cap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

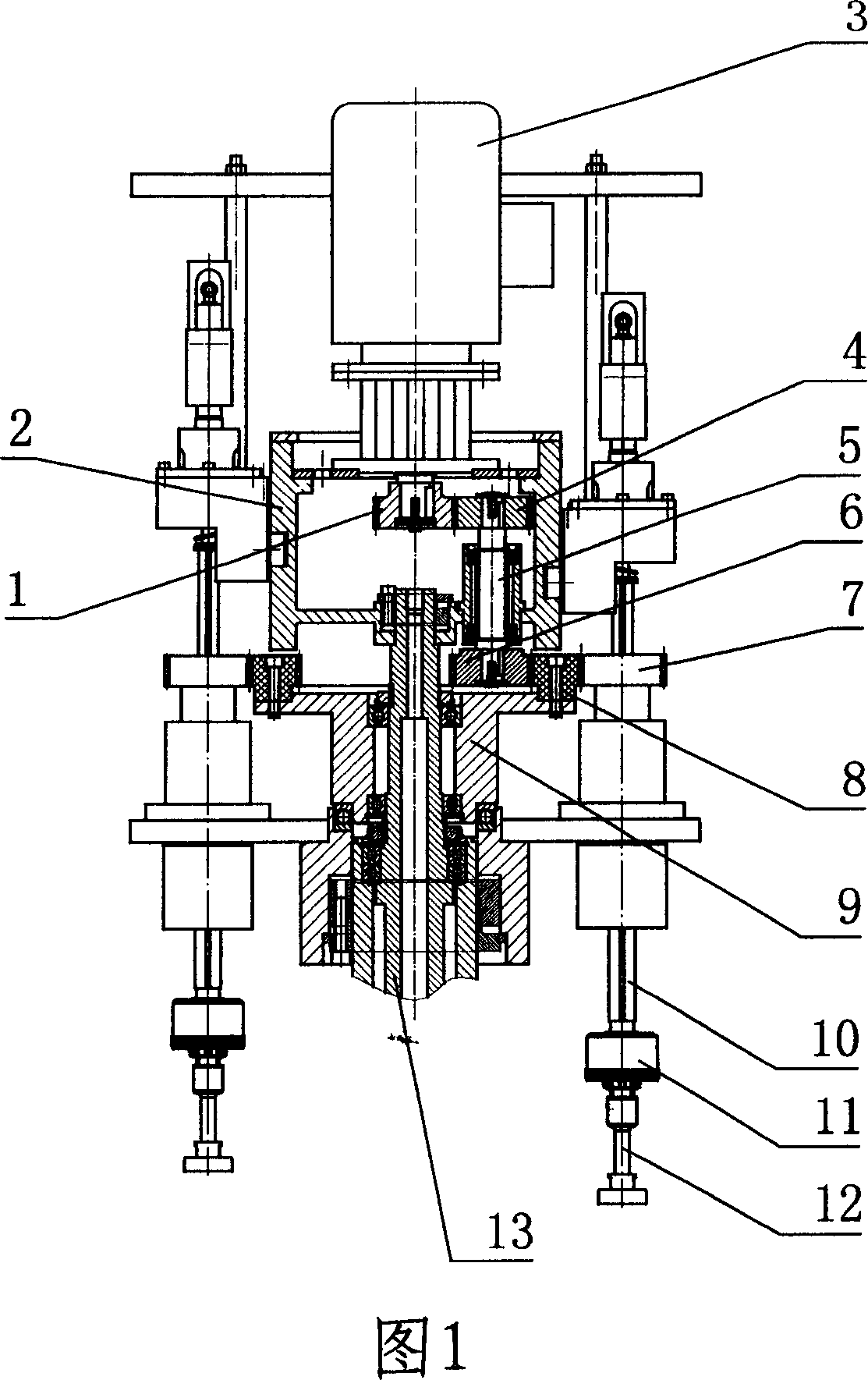

[0007] The present invention will be further described below in conjunction with the capping mechanism of 8 capping heads in conjunction with accompanying drawing:

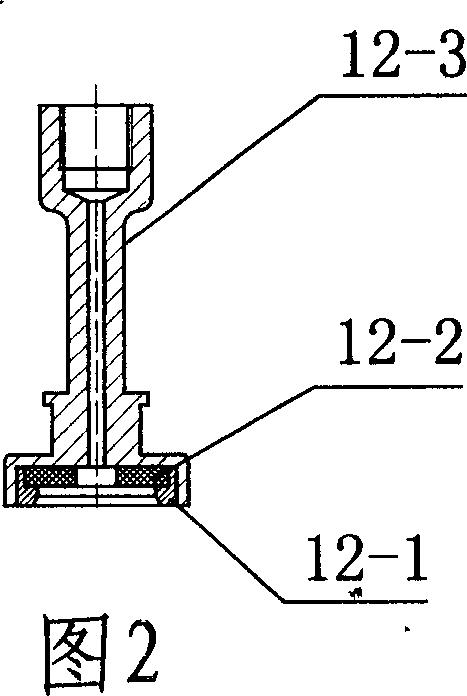

[0008] See accompanying drawings 1 and 2, the motor reducer 3 is fixed on the middle cylindrical cam 2, the middle cylindrical cam 2 is fixed on the central fixed shaft 13 with an expansion sleeve, the reducer gear 1 is fixed on the shaft head of the motor reducer 3, The reducer gear 1 meshes with the upper gear 4, the upper gear 4, the gear shaft 5, and the lower gear 6 are fixed on the middle cylindrical cam 2 through the bearing seat, the lower gear 6 meshes with the internal teeth of the middle gear 8, and the middle gear 8 is fixed in the middle On the gear fixing seat 9, the intermediate gear fixing seat 9 is positioned on the central fixed shaft 13 through bearings, the outer teeth of the intermediate gear 8 mesh with the gear 7, the gear 7 is connected to the transmission shaft 10, the transmission shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com