Open-type hydraulic torque wrench

A torque wrench, open-ended technology, applied in the field of hydraulic tools, can solve the problem of difficult control of tightening torque, and achieve the effect of simple structure, accurate torque setting and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] a), set torque:

[0013] The working torque of the present invention is directly proportional to the working pressure of the hydraulic system. The present invention is provided with a torque comparison table on the wrench body 1, and the working pressure value of the hydraulic system is correspondingly set according to the torque value set by the nut to be tightened.

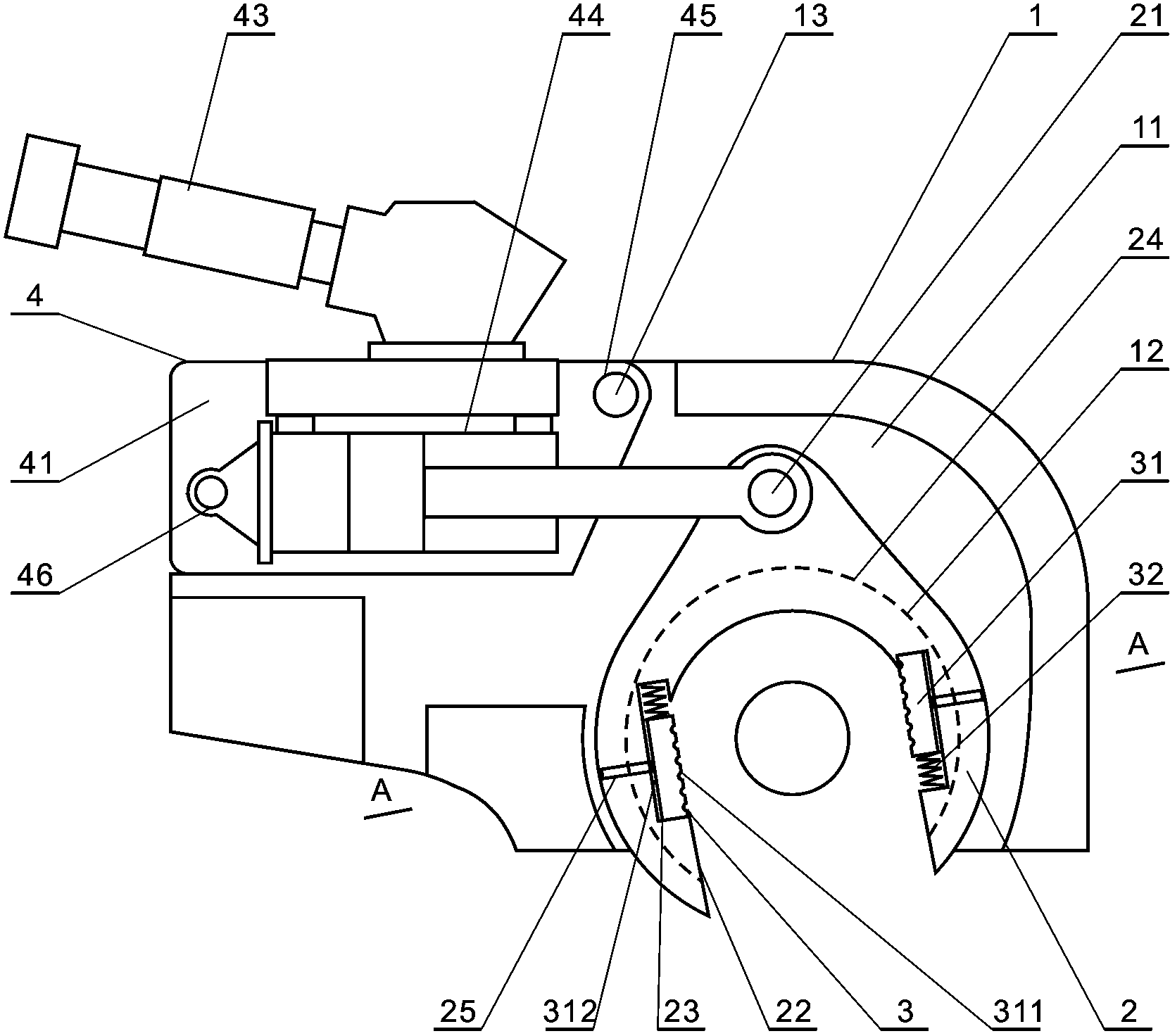

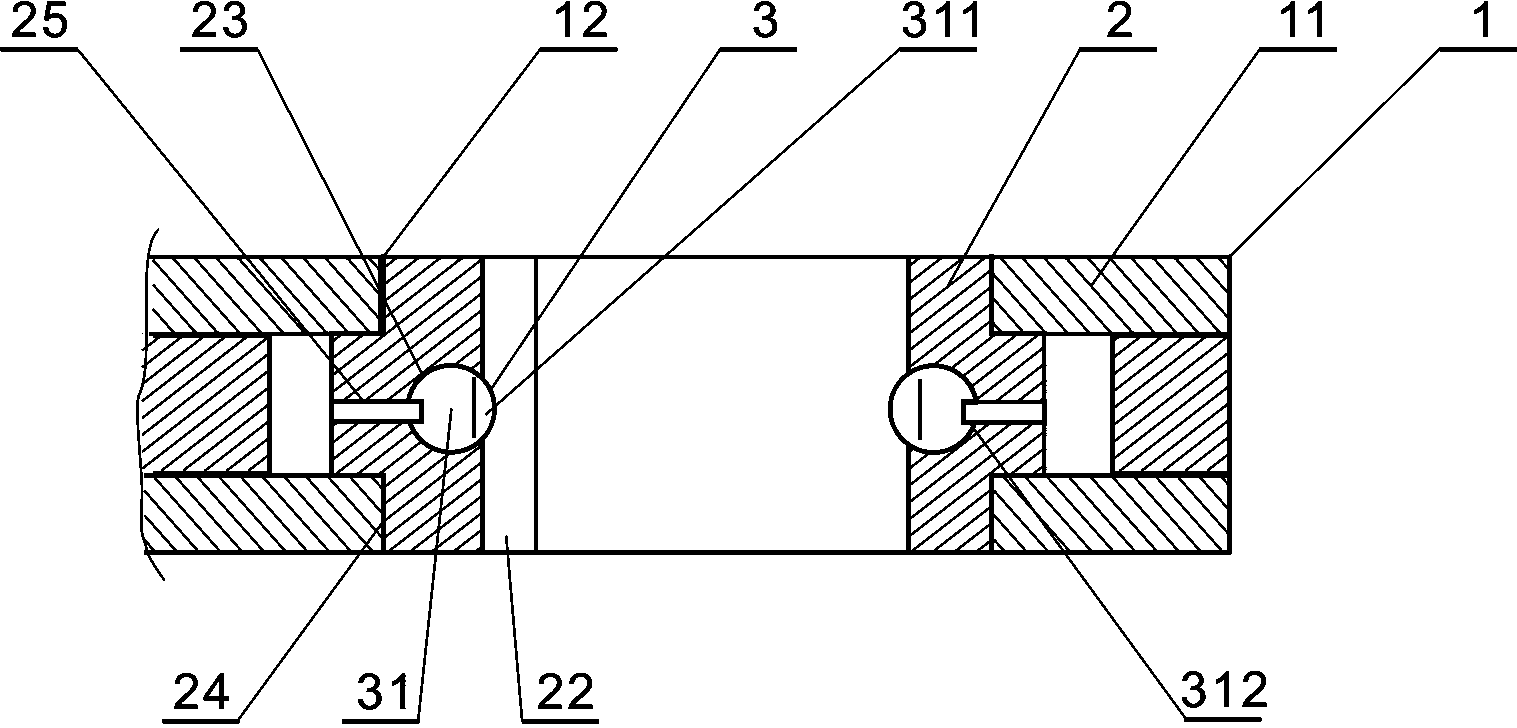

[0014] b), Install the wrench head:

[0015] refer to figure 1 , figure 2 , select the wrench head 2 corresponding to the size of the nut, open a side wall plate 11 of the wrench body 1, set the boss 24 of the wrench head 2 in the open hole 12 of the wrench body 1, and place the wrench head 2 The hinge shaft 21 is hinged with the piston rod of the oil cylinder 44, and finally, the side wall plate 11 of the wrench body 1 is covered and fastened.

[0016] c), the present invention works like this:

[0017] refer to figure 1 , figure 2 , the opening 22 of the wrench head 2 is clamped on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com