A ship hull and method of manufacturing such a hull

A technology for ship hulls and ships, applied in the direction of ship hulls, ship construction, hull components, etc., can solve problems such as rupture, outer shell deformation, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Before deformation occurs, the density is 100kg / m 3 The foam PVC can withstand 280ton / m 2 load. In this case, no surface layer is required on the upper surface of the foamed plastic material. The density is 200kg / m 3 The foam PVC can withstand 500ton / m 2 load.

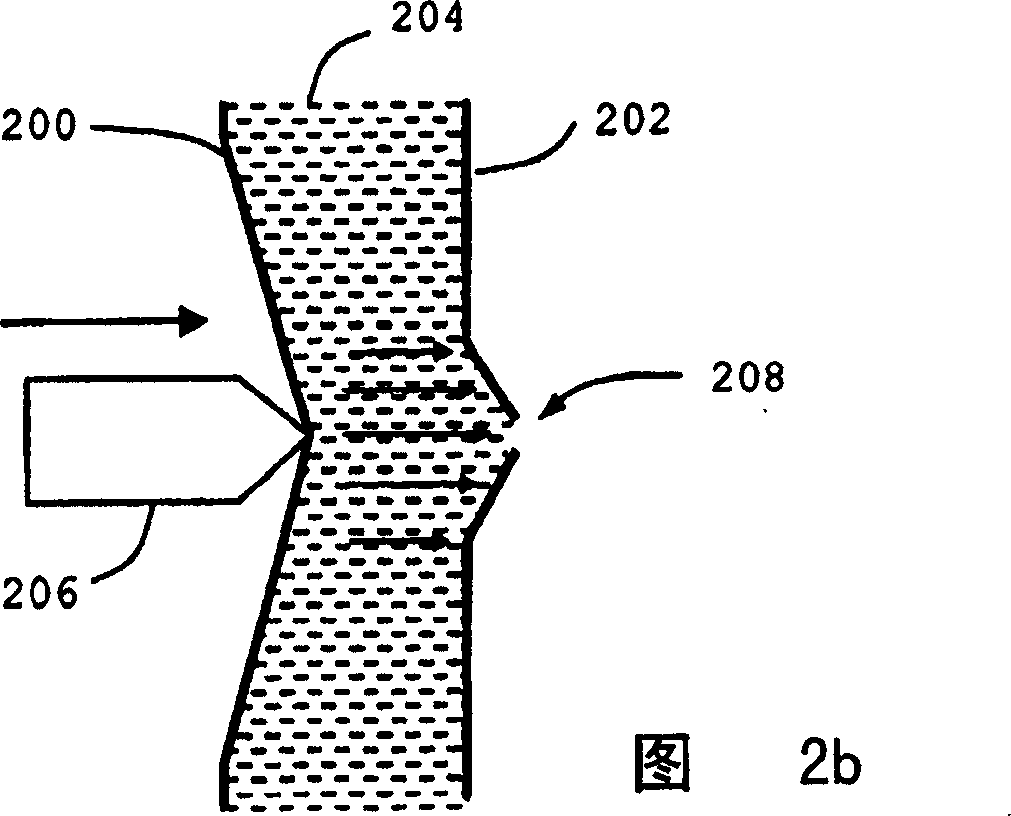

[0085] When deformation occurs, the outer layer begins to deform first, and to further deform the foam, the pressure must be doubled. This fact, combined with a hardened surface layer on the foam surface which distributes the pressure over a larger area, makes it possible that the energy absorption capacity of the structure according to the invention is exceptionally high.

[0086] Additional advantages can be brought about when using foamed polypropylene or foamed polyethylene. After compression, the foamed plastic material recovers almost to its original thickness, but this is also somewhat dependent on the nature of the damage.

[0087] Another advantage brought about by the present invention is related...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com