Plastic suction forming apparatus

A technology of plastic forming machine and forming device, which is applied in the direction of metal processing, etc., can solve the problems of excessive manpower, low degree of automation, and low work efficiency, and achieve the effects of saving labor, improving production efficiency, and occupying a small area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

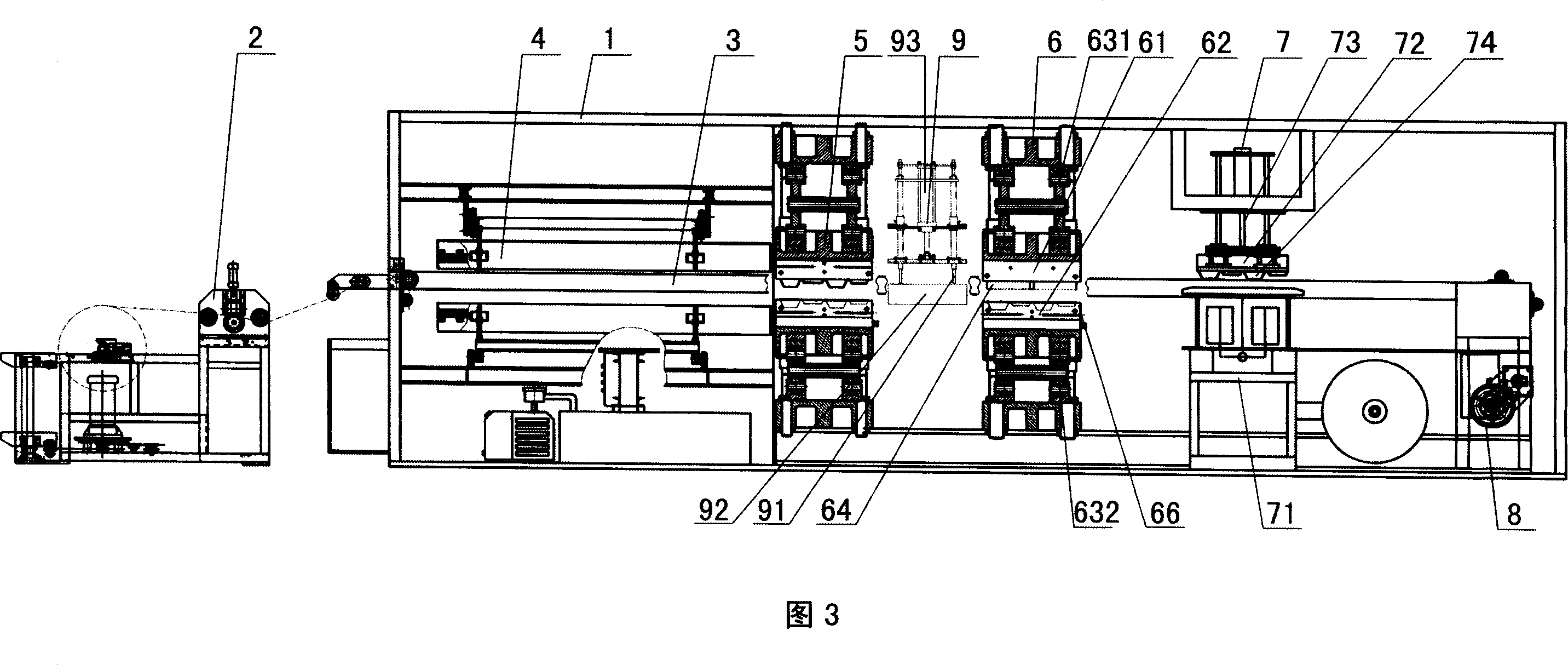

[0018] As shown in Figure 1, this blister forming machine includes a frame 1, a sheet material supply device 2, a sheet feeding device 3, a heating device 4, a forming device 5, a cutting device 6, a product stacking device 7 and a surplus material winding device 8, wherein the sheet supply device 2 is arranged in front of the sheet feeding device 3, the sheet feeding device 3 is arranged on the frame 1, the heating device 4, the forming device 5, the cutting device 6, the product stacking device 7 and the remaining material winding device 8 Set on rack 1 in turn.

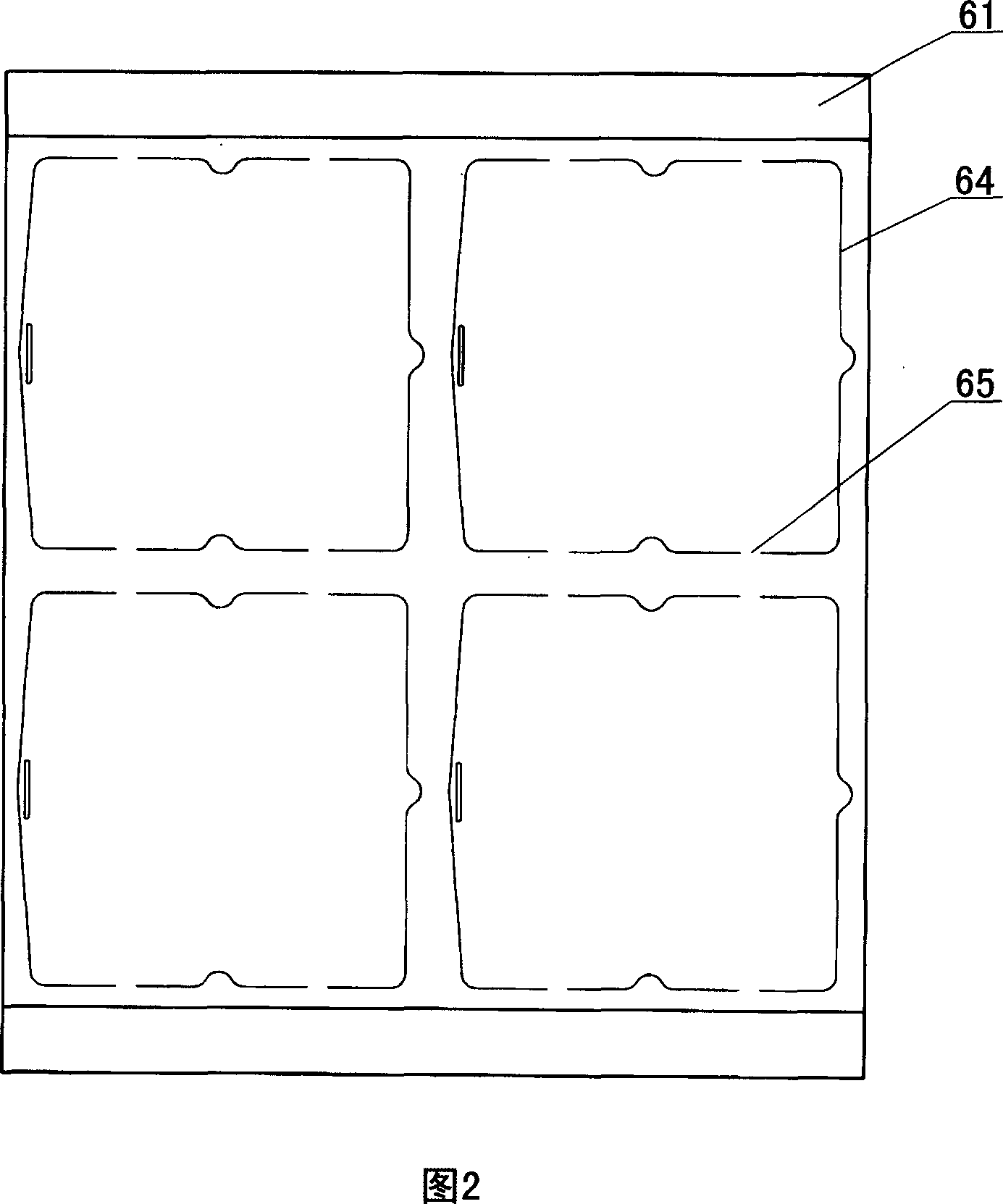

[0019] The cutting device 6 includes an upper mold 61, a lower mold 62, and a mold opening and closing control mechanism. As shown in Figure 2, upper mold 61 is provided with cutting knife 64, and the shape of cutting knife 64 matches the shape of product outline; The quantity and arrangement of cutting knife 64 are consistent with the mold in molding device 5; Ring shape, the cutting knife 64 is provided with a p...

Embodiment 2

[0023] As shown in Figure 3, a punching device 9 is arranged between the molding device 5 and the cutting device 6 of this plastic forming machine, the punching device 9 is installed on the frame 1, and the punching device 9 includes a punch 91, a punch Lifting control mechanism and chopping block 92, punching rod 91 is connected with punching rod lifting control mechanism, and cutting block 92 is provided with the hole corresponding with punching rod 91, and punching rod lifting control mechanism comprises cylinder 93, and the cylinder block of cylinder 93 is fixedly installed on the machine. On the frame 1, the piston rod is connected with the punch rod 91, and other structures are the same as in Embodiment 1. The formed product is first punched at a suitable position by the punching device 9, and then cut. This blister forming machine is suitable for the production of products that need to be set with holes.

Embodiment 3

[0025] As shown in Figure 4, a heating device 10 is arranged between the molding device 5 and the cutting device 6 of this plastic forming machine, the heating device 10 is installed on the frame 1, the heating device 10 includes a box body, and the box body is arranged On the top of the formed product, a plurality of electrothermal optical tubes and a fan are arranged in the box body, and an air outlet is provided at the bottom of the box body, and the electrothermal optical tube is arranged between the fan and the air outlet, and other structures are the same as in Example 1 . The heating device 10 heats the shaped product to maintain a relatively stable temperature, and then cuts it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com