Water using wipe floor cleaning machine

A technology for cleaning machines and rags, applied in the directions of cleaning machinery, cleaning equipment, applications, etc., can solve the problems of not providing a new device that can imitate manual wiping mode with a rag, and the level of automation is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

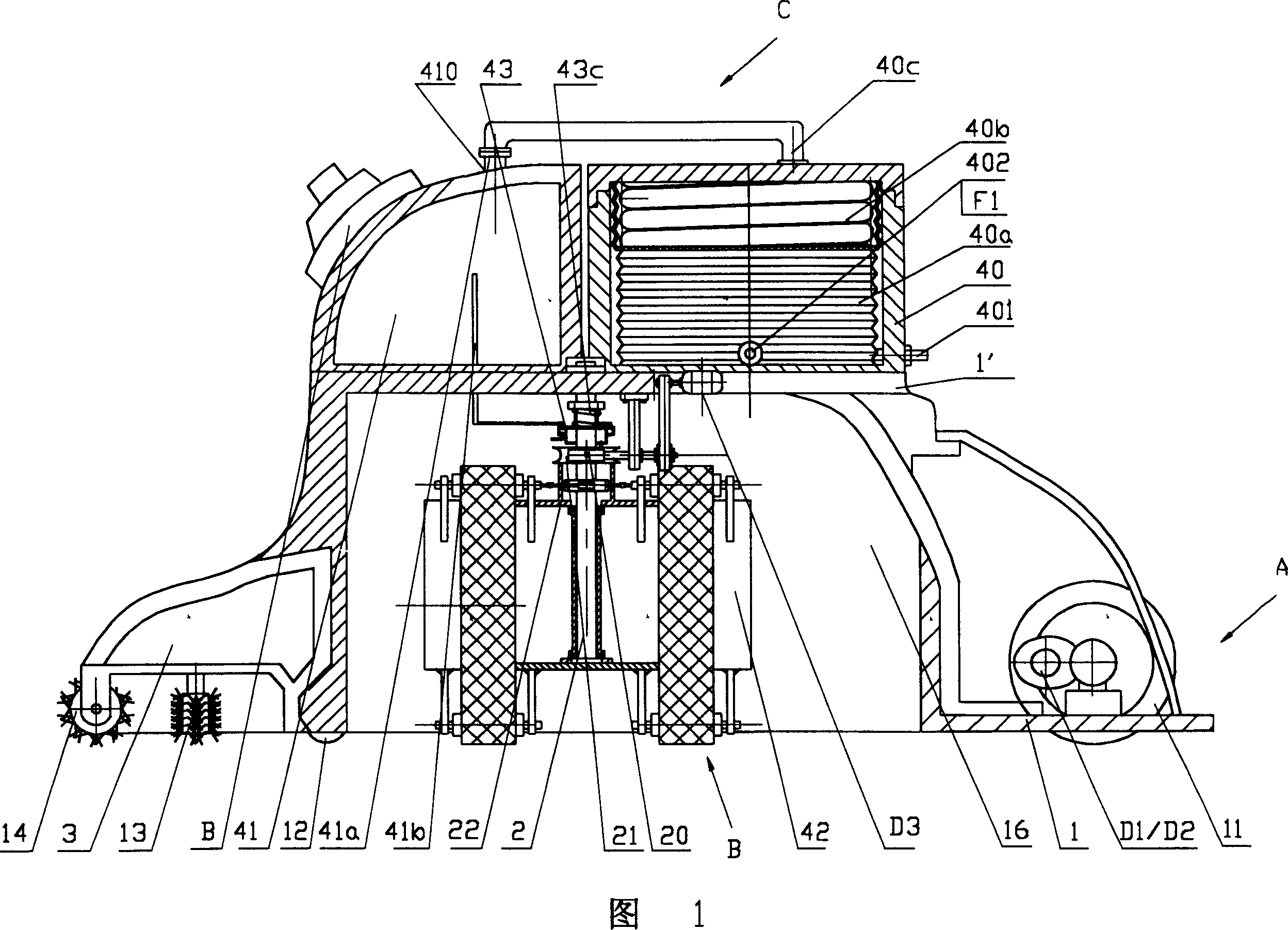

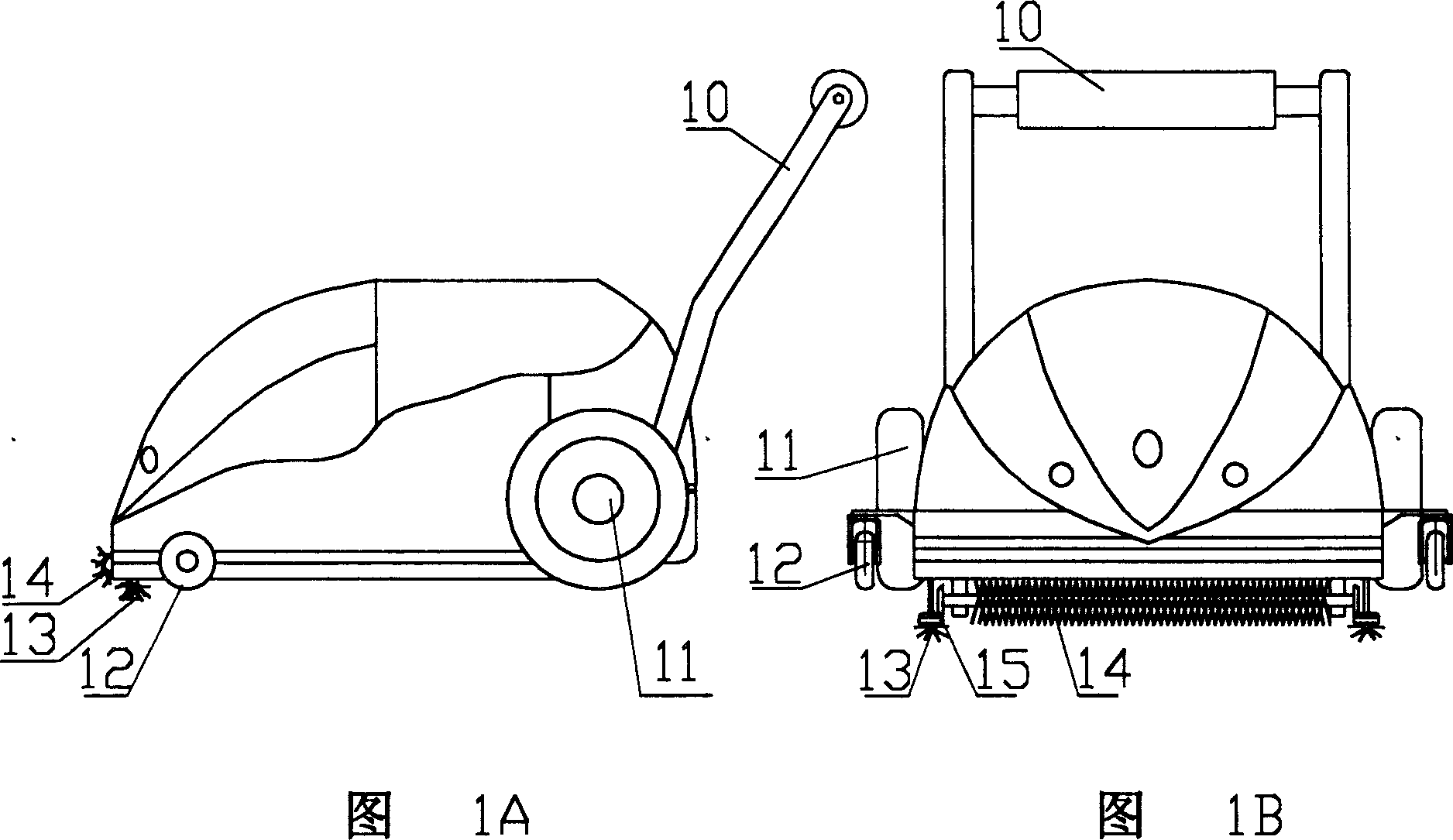

[0058] As shown in Fig. 1, Fig. 1A and Fig. 1B, and Fig. 2-7, it is a kind of water rag cleaning machine of structure, and the described walking part A includes a frame 1, and the lower surface of the frame 1 is provided with There are two rear drive wheels 11, which are fixed on the rear axle assembly on the frame. Also be provided with front guide wheel 12 in the front of this frame 1. In use, push this frame 1 to walk back and forth in the room by the handrail 10 on the frame 1, like this, can make this mopping floor cleaning machine pass through various places in the room, all grounds are wiped. It is also possible to establish two motors D1 and D2 on the frame to be connected with the two rear driving wheels, to drive the floor cleaning machine to walk through the motors, so that it drives the cleaning machine to go straight, turn or turn around (about automatic control and remote control) The structure is described later);

[0059] The front of frame 1 is provided with...

Embodiment 2

[0088] As shown in Fig. 9A-Fig. 9E, it is another structure of the mopping and cleaning machine, wherein the frame, driving device, fixed shaft and turntable support are basically the same as those in Embodiment 1. The difference lies in the rag wiping device in the cleaning section.

[0089] This rag wiping device is still a kind of rag belt transmission, but the structure of said rag belt transmission is:

[0090] The frame 1' is extended with a fixed fixed shaft 2', and a large toothed disc 91 is sleeved on it. A drive motor D3 is fixed on the frame, and a worm 92 is fixed on the output shaft of the motor, which can also be rotated on the frame. A transmission gear fixed frame shaft 93 is fixedly installed on it, and a worm wheel 94 and a transmission pinion 95 are fixedly installed on it. The worm wheel 94 meshes with the worm 92, and the pinion meshes with the large toothed disc 91 sleeved on the fixed shaft 2'. Make the large toothed disc 91 rotate around the fixed shaf...

Embodiment 3

[0100]As shown in FIG. 10A-FIG. 10D , this embodiment provided by the present invention is to solve the problem of cleaning the floor under the furniture cover. Other structures are as embodiment 1 and 2, and it just improves on frame. The frame of the walking part is about to become a split frame consisting of a main frame 101 and a short frame 102 that can be extended and retracted, two rear driving wheels 11, a clean water tank 40 and a sewage tank 41 is installed on the main frame 101, the front guide wheel 12 is arranged on the low frame 102, the fixed shaft is arranged on the low frame 102, and the cleaning tank 42 in the cleaning part and the water system is arranged on the low frame On the frame 102; the bottom of the main frame 101 is provided with an accommodating space that can accommodate the short frame 102 and can make it extend and retract, and a rigid telescopic tube 103 is provided on the low frame 102, correspondingly, The frame 101 is also provided with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com