Mass spectrum equipment of accelerator, and method for measuring mass spectrum 14C of accelerator

An accelerator mass spectrometry and accelerator technology, applied in the field of accelerator mass spectrometry, can solve the problems of unfavorable environmental protection, complex injection system, inconvenient operation and other problems, and achieve the effects of environmental protection, convenient maintenance and operation, and simple environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

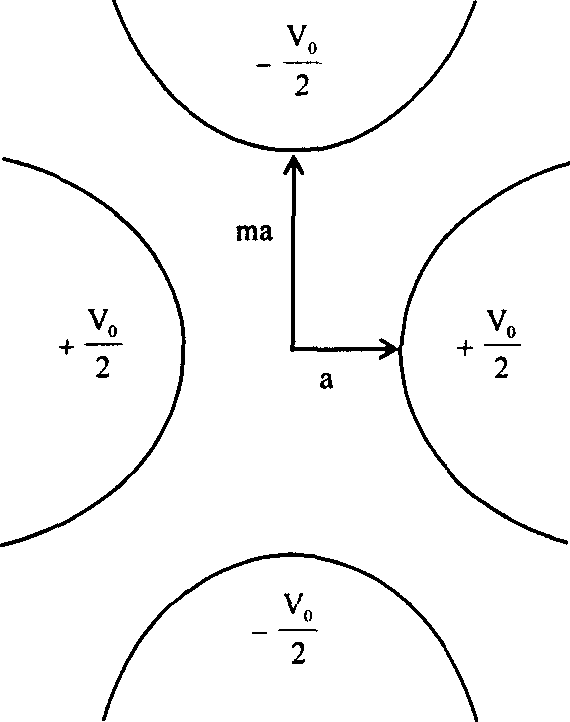

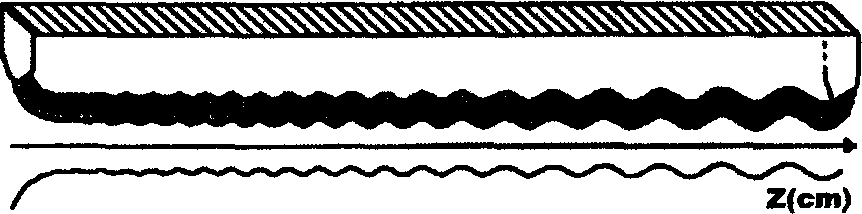

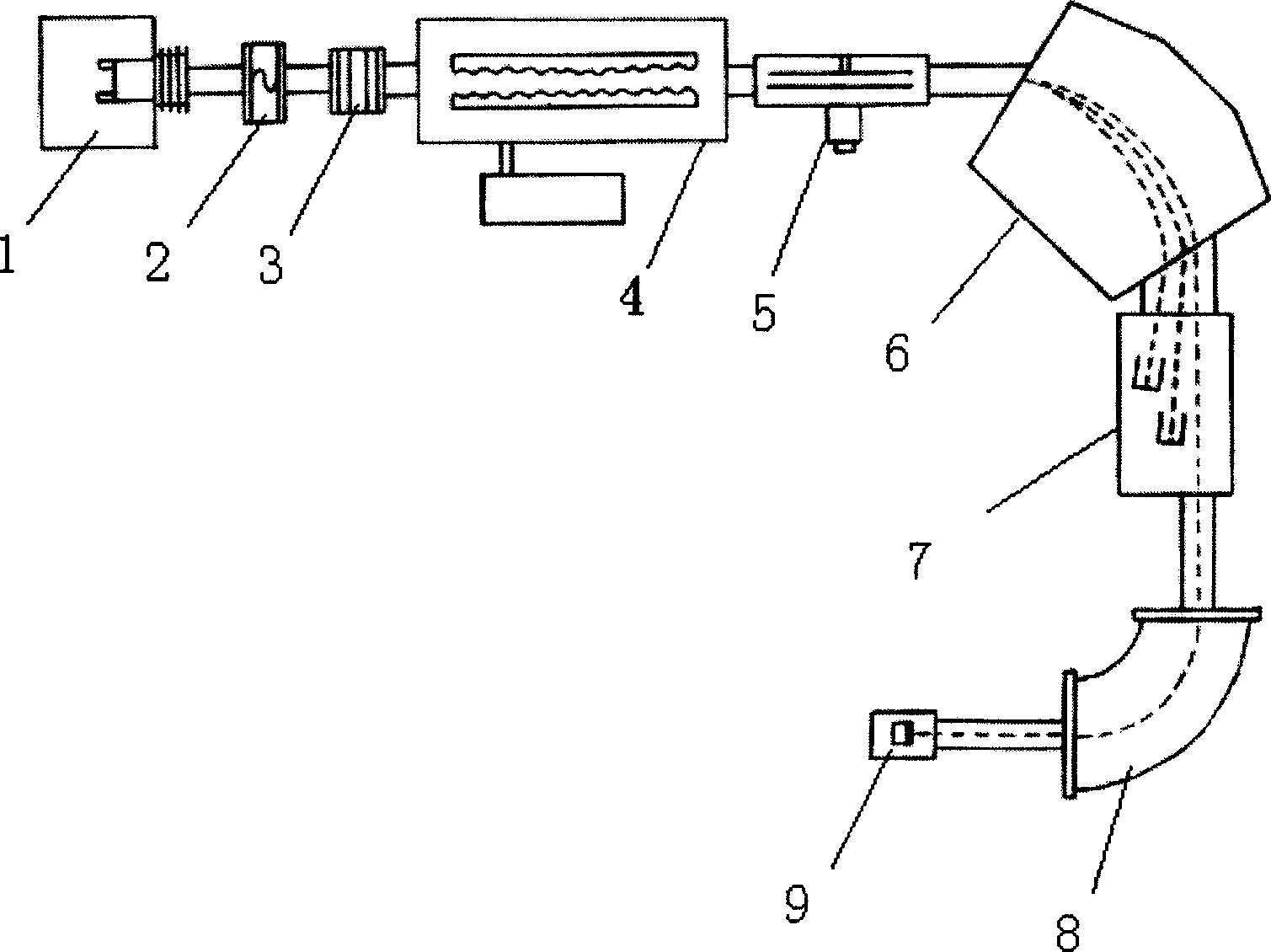

[0030] The main difference from other AMS systems is that the present invention uses an RFQ accelerator. The RFQ accelerator has the characteristics of high beam transmission efficiency and small size, but the energy dissipation of the output beam is relatively large, generally around 1%. According to the requirements of AMS technology, the exit of RFQ accelerator 14 The C beam energy dispersion is preferably less than 0.5%. The present invention adopts external beamforming RFQ accelerator, carries out pulse beam current injection by adding buncher at the front end of RFQ accelerator, adopts to increase the synchronous phase of accelerating section and reduce the modulation coefficient m of accelerating section electrode in the design of RFQ accelerating electrode simultaneously (referring to Figure 1) and other measures can realize the low energy dispersion characteristic of the output beam of the RFQ accelerator. This enables a significant improvement in energy dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com