Absorption mode refrigerator of hot water type lithium bromide between single action and two stages

An absorption refrigerator, lithium bromide technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of multiple collector areas, low efficiency, poor economy, etc., and achieve the effect of a reasonable overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

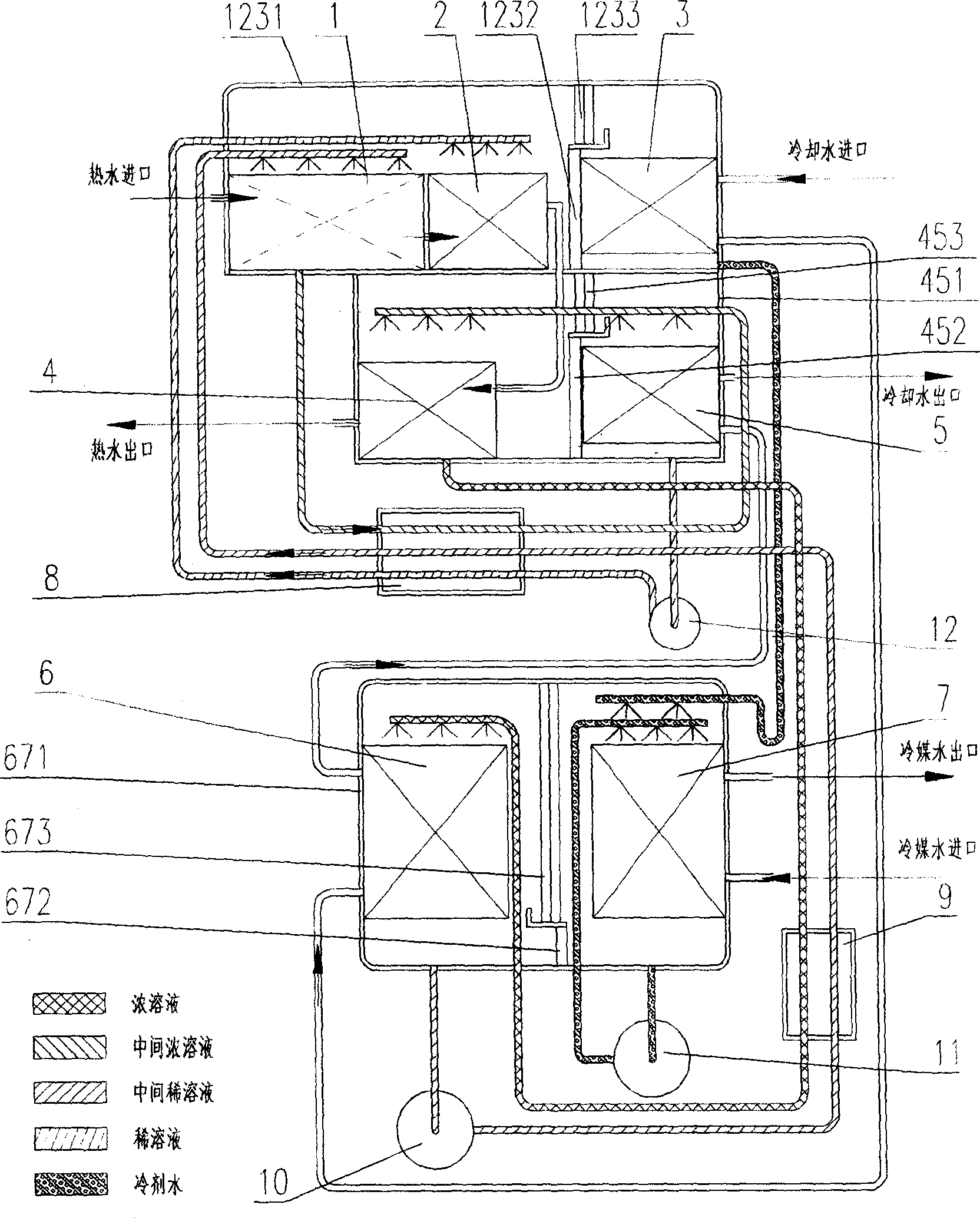

[0017] Example 1 see figure 1 , a hot water lithium bromide absorption refrigerator, comprising a first high-pressure generator 1, a second high-pressure generator 2, a condenser 3, a medium-pressure generator 4, a medium-pressure absorber 5, a low-pressure absorber 6, and an evaporator 7. The high-temperature solution heat exchanger 8, the low-temperature solution heat exchanger 9, the solution pump 10, the refrigerant pump 11, the solution pump 12 and connecting pipelines, the refrigerant water outlet of the condenser 3 uses a U-shaped tube and the evaporator 7 The refrigerant water inlet is connected, the refrigerant water outlet at the bottom of the evaporator 7 is connected to the inlet of the refrigerant pump 11, and the outlet of the refrigerant pump 11 is connected to the inlet of the refrigerant water spray pipe above the heat transfer core of the evaporator 7; The concentrated solution outlet at the bottom of the medium pressure generator 4 is connected to the concen...

Embodiment 2

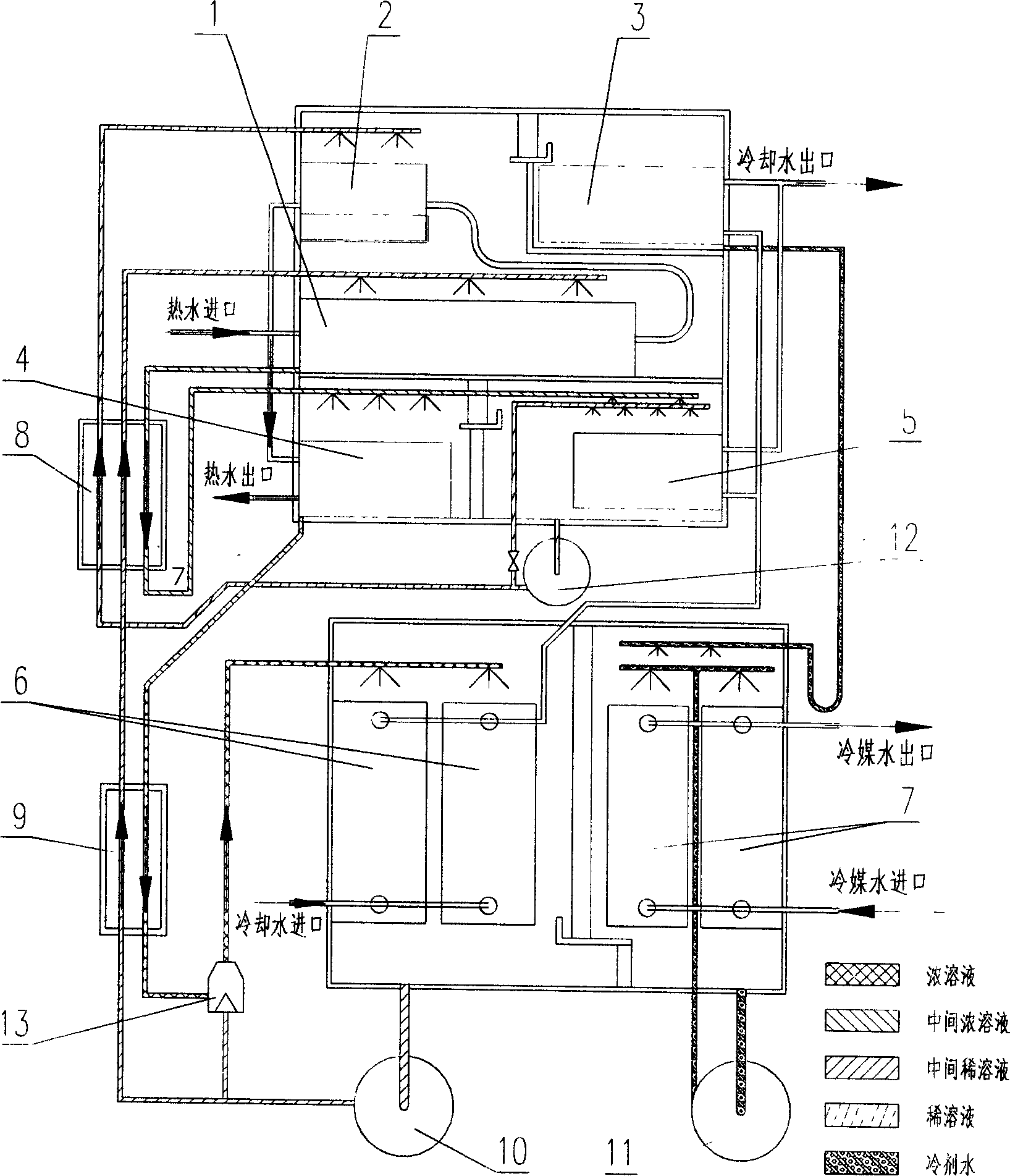

[0019] Example 2 see figure 2 , first of all, the above-mentioned three heat exchangers on the uppermost layer can be arranged in another way, that is, the second high-pressure generator 2 and the condenser 3 are arranged side by side, leaving a steam channel between them, and the first high-pressure generator 1 is arranged in the Below them; Secondly, the outlet of the solution pump 12 below the medium-pressure absorber 5 is provided with a recirculation spray circuit to increase the solution spray volume of the medium-pressure absorber 5: the solution pump 10 below the low-pressure absorber 6 The outlet of the evaporator 13 bypass pipeline is set to increase the solution spraying amount of the low-pressure absorber 6 and improve the heat and mass transfer efficiency of the absorption process; in addition, both the evaporator 7 and the low-pressure absorber 6 can be configured with 2 groups or Two or more sets of heat exchangers arranged in parallel.

Embodiment 3

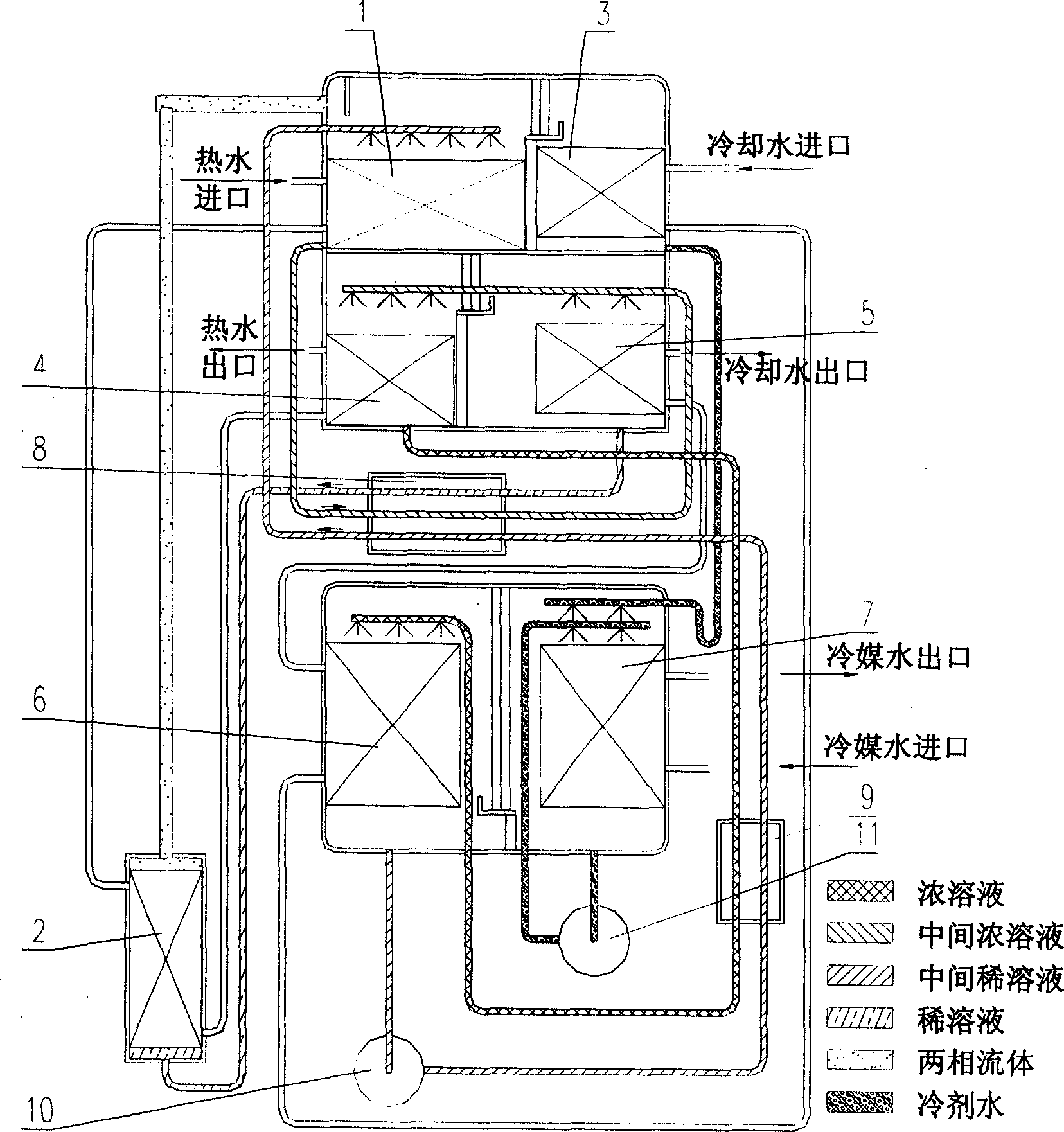

[0020] Example 3 see image 3 , the above-mentioned second high-pressure generator 2 can also adopt another arrangement, that is, the second high-pressure generator 2 is arranged at a low position, and the dilute solution inlet at the lower part of the second high-pressure generator 2 is connected with the dilute solution outlet of the high-temperature solution heat exchanger 8 connection; the dilute solution inlet of the high-temperature solution heat exchanger 8 is connected with the dilute solution outlet at the bottom of the medium-pressure absorber 5; the vapor-liquid two-phase fluid outlet of the second high-pressure generator 2 is connected to the first high-pressure generator 1 through a liquid lift pipe The gas-liquid two-phase fluid inlet is connected; therefore, a sufficient liquid column is established in the connecting pipe from the medium-pressure absorber to the second high-pressure generator through the high-temperature solution heat exchanger to balance the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com