Composition of baffle for generating vortex liquid state flow or vortex l combustive flow

A technology of combined structure and liquid state, applied in the direction of combustion chamber, combustion method, combined device, etc., can solve the problems of inability to achieve economy, inability to achieve economic practicability, and insignificant results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

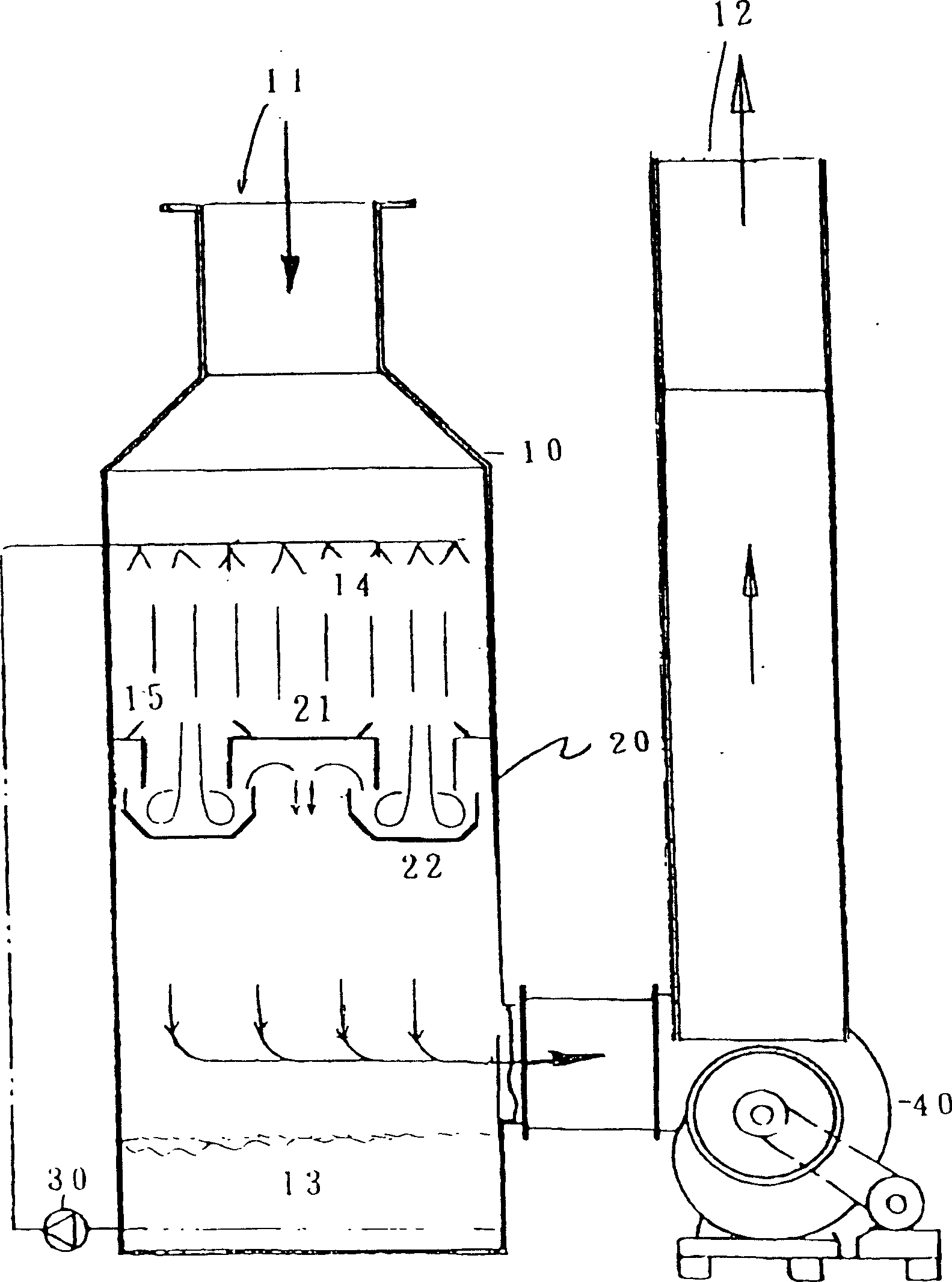

[0089] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the baffle combined structure according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The description is as follows. The baffle plate combination structure of the present invention can be installed in a new-type washing tower, and can also be installed in an old-type packing material washing tower to replace the use of filling materials. Various types of baffles are made of metal materials. In addition, in the present invention, each "", " / _\", and ″\_ / ″, ″ ̄\ ̄ /  ̄″, ″∧_∧″ are integrally formed structures, please refer to the attached drawings for the specific shape, and the above symbols do not limit the shape of the baffle.

[0090] see Figure 2 to Figure 5 , Figure 10 , Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com