Cable connector

A cable connector and connector technology, applied in the direction of cable joints, clamping/spring connections, etc., can solve the problems of erosion, reduce cable life and line operation level, time-consuming and labor-intensive, etc. Effective operation and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

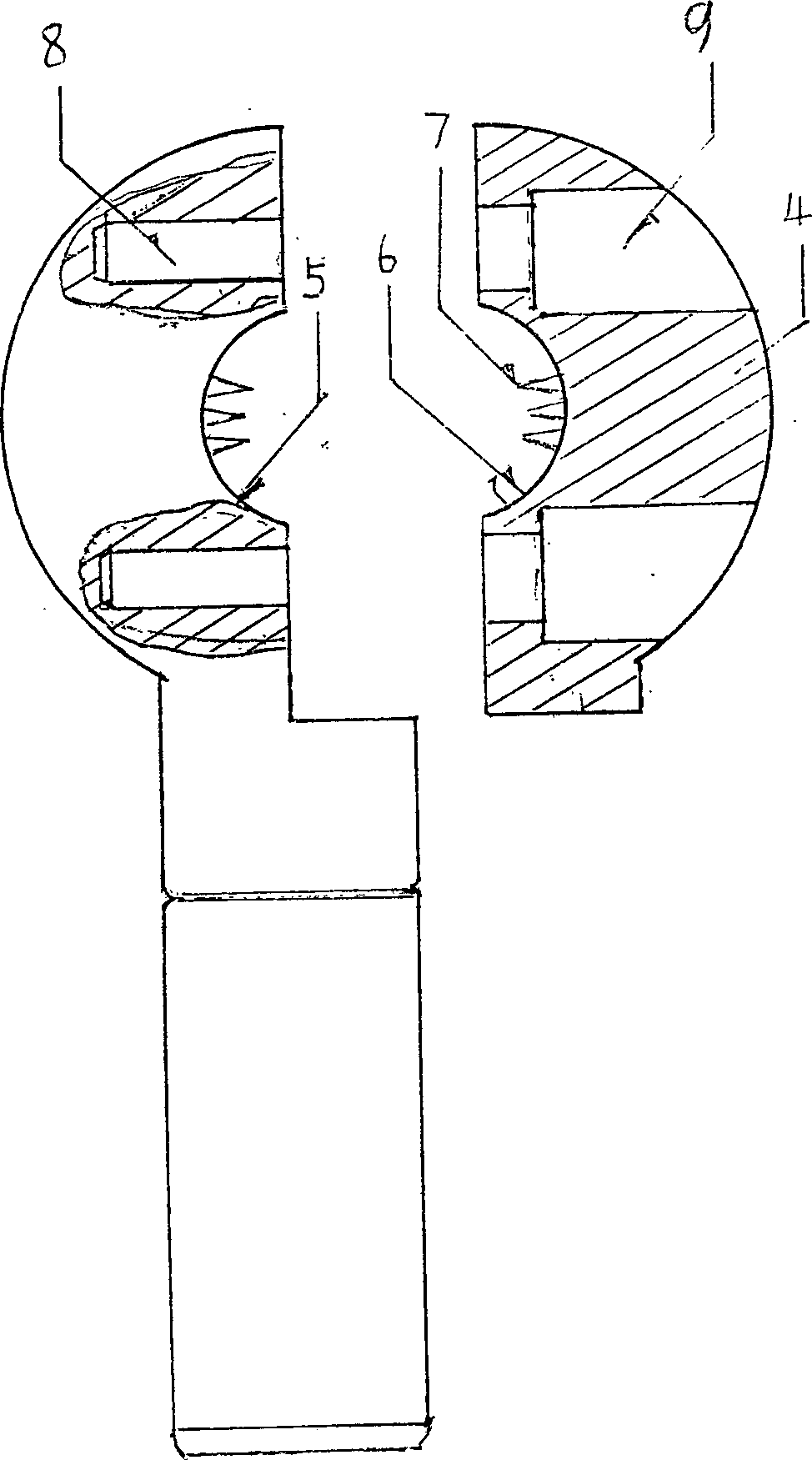

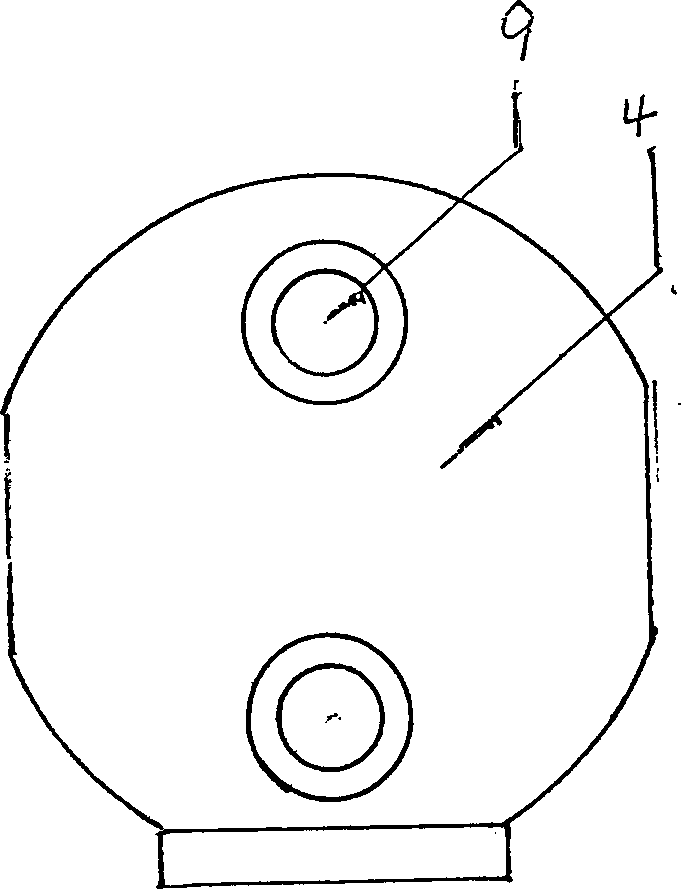

[0011] See Figure 1-3 The specific structure is as follows, the lower part of the connector body is a vertical cylinder 2, a section of aluminum pipe or copper pipe 3 is connected to the cylinder through threaded fitting, the upper part of the cylinder is the main connecting body 1, and the main connecting body 1 is connected by connecting bolts. Firmware 4, two clamping inner arc surfaces 5 and 6 are set at the place where the main connecting body, the clamping member and the cable are in contact, and the conical clamping bar 7 is arranged on the clamping inner arc surface, and the main body clamps of the connector are all made of aluminum alloy Die-casting, the conical barbs 7 are given by casting at the same time, both of which are excellent electrical conductors. When in use, strip off a section of insulation at the end of the branch cable in advance, insert the conductor after stripping the insulation into the aluminum tube or copper tube 3, and press the aluminum tube a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com