Join pipe structure of refrigeration equipment

A refrigeration equipment and piping technology, which is applied to refrigerators, refrigeration components, mechanical equipment, etc., can solve problems such as unsatisfactory vibration damping effect, high material cost, and large piping stress, so as to improve vibration, noise and stress conditions, and improve work efficiency. Reliability, the effect of reducing pipeline stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

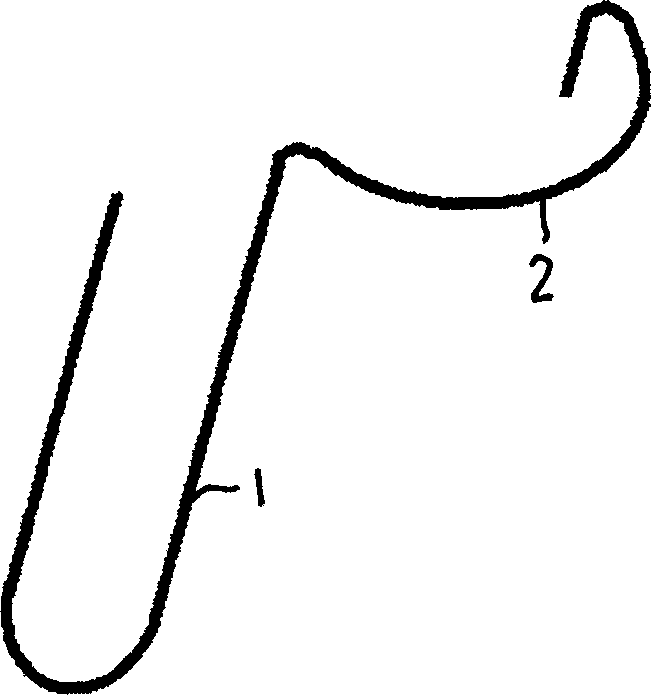

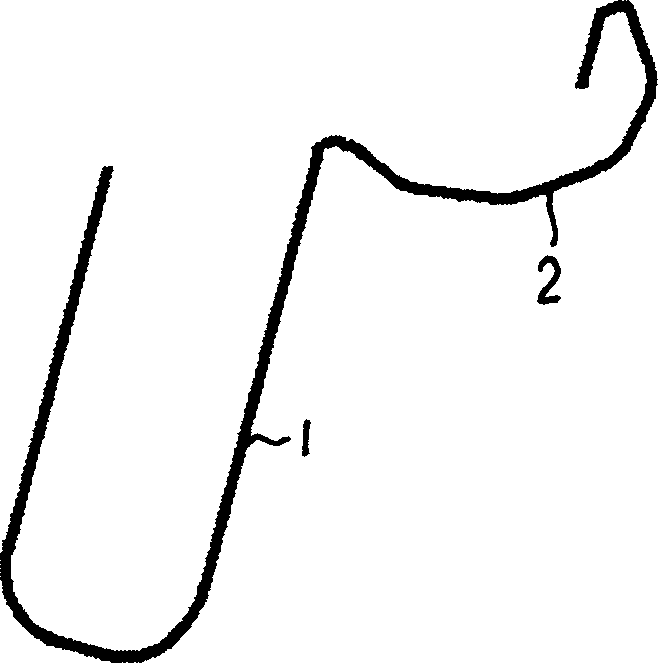

[0013] see figure 1 , figure 2 , the combined structure of two arc-shaped pipes arranged on different planes, one is the "U"-shaped pipe 1 arranged in the vertical plane around the circumference of the compressor; the other is the angle less than 60° with the horizontal plane The arc tube 2 in the plane.

[0014] In specific implementation, the following various structural forms can be adopted:

[0015] 1. The arc tube 2 is arc-shaped;

[0016] 2. The arc tube 2 is composed of at least two arc tubes with different curvatures that are smoothly connected to form a non-full circle arc.

[0017] 3. The arc-shaped pipe 2 is formed by the gradual bending and transition of multiple straight pipe sections. figure 2 structure shown.

[0018] Can take the form of a structure also includes:

[0019] 4. The bottom of the "U"-shaped pipe 1 is an arc-shaped pipe segment ( figure 1 shown).

[0020] 5. The bottom of the "U"-shaped pipe 1 is a straight pipe section connected between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com