Preparation method of natural benzaldehyde

A technology of benzaldehyde and natural cinnamic aldehyde, which is applied in the field of preparation of natural benzaldehyde, can solve the problems of high price, slow reaction speed, and low product quality, and achieve the effects of guaranteed quality, not easy polycondensation, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

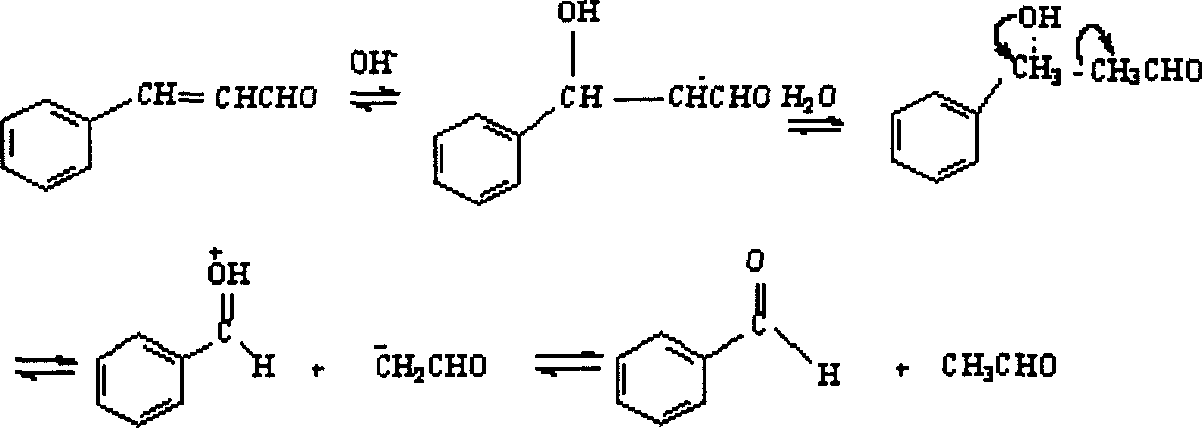

Method used

Image

Examples

Embodiment 1

[0018] 500 kilograms of weight concentration is that 2% sodium hydroxide aqueous solution is added in the reactor that top is provided with rectifying device, is heated to boiling, then 200 kilograms of cinnamic aldehydes are added reactor and react, generate natural benzaldehyde and acetaldehyde, and Through the rectification device, the natural benzaldehyde and acetaldehyde generated during the reaction process are continuously removed from the top of the rectification device by means of rectification, and part of the discharged natural benzaldehyde gas is condensed and refluxed, and part of it is sent as a product to the subsequent In the working section, the discharged acetaldehyde gas is collected for later use, and the reflux ratio of rectification is 2.5;

[0019] After reacting for 10 hours, 140 kg of natural benzaldehyde with a weight concentration of 95% was obtained, and the reaction yield was 83%.

Embodiment 2

[0021] 200 kilograms of weight concentration is that 5% sodium carbonate aqueous solution is added in the reactor that top is provided with rectifying device, is heated to boiling, then 80 kilograms of natural cinnamic aldehydes are added reactor and react, generate natural benzaldehyde and acetaldehyde, and Through the rectification device, the natural benzaldehyde and acetaldehyde generated during the reaction process are continuously removed from the top of the rectification device by means of rectification, and part of the discharged natural benzaldehyde gas is condensed and refluxed, and part of it is sent as a product to the subsequent In the working section, the discharged acetaldehyde gas is collected for later use, and the reflux ratio of rectification is 3;

[0022] After 12 hours of reaction, 54 kg of natural benzaldehyde with a weight concentration of 94% was obtained, and the reaction yield was 79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com