Valve operating device for engine

An engine valve and transmission technology, which is applied to engine components, machines/engines, valve devices, etc., can solve the problems of unsatisfactory follow-up of engine valve opening and closing actions, and achieve good follow-up and easy positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

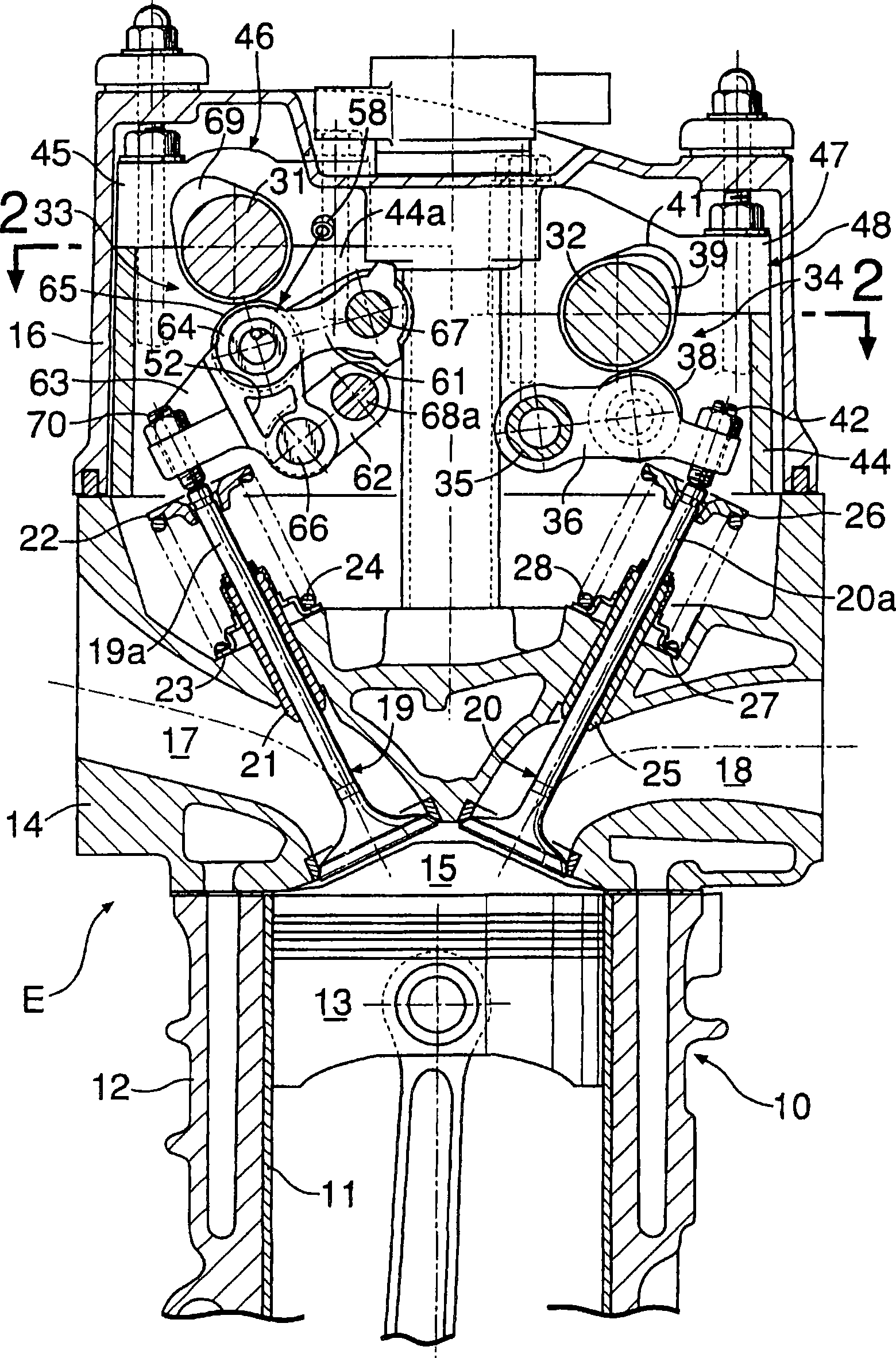

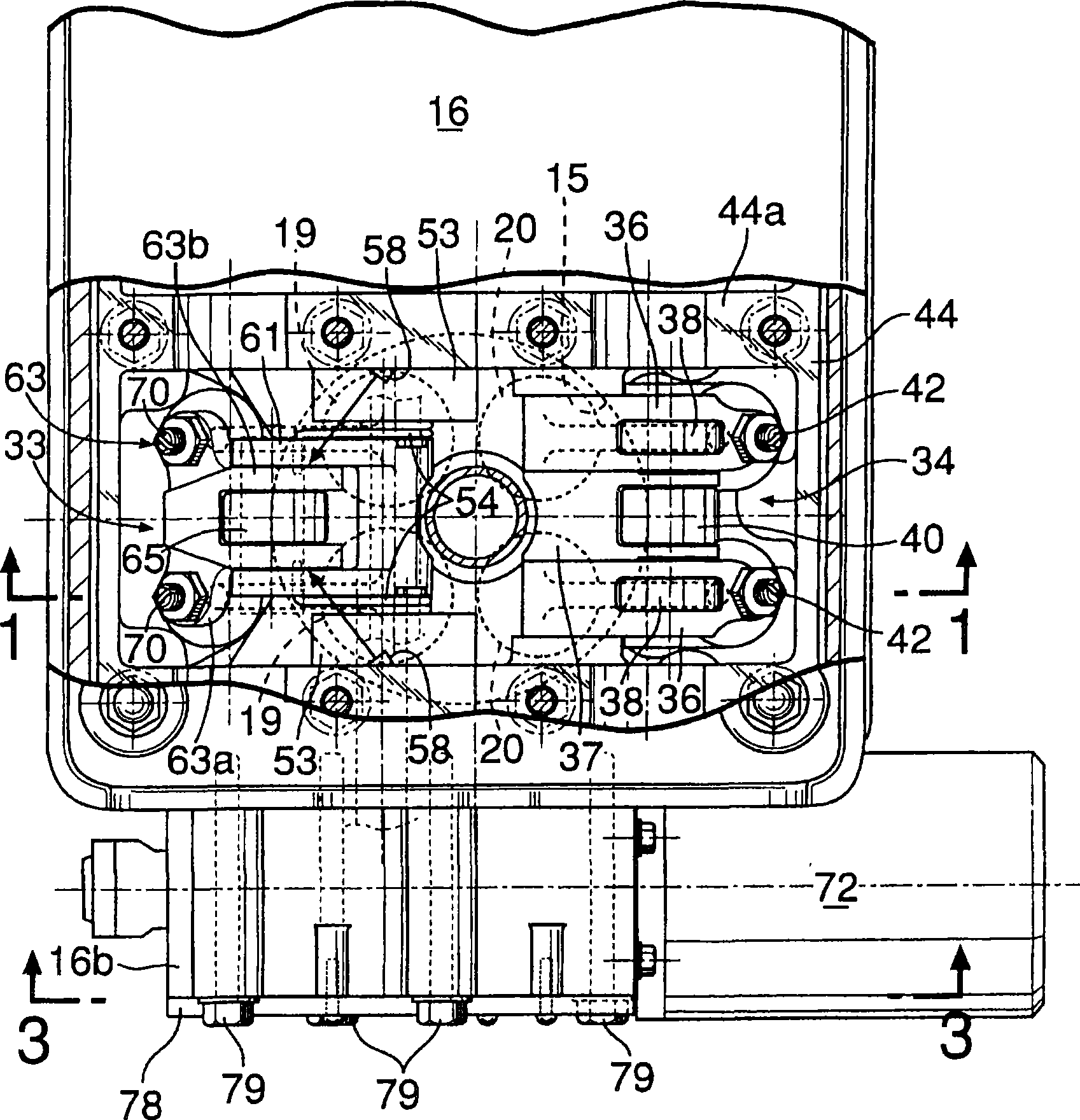

[0053] Figure 1 to Figure 11 Shows the first embodiment of the present invention.

[0054] first in figure 1 Among them, the engine body 10 of the in-line multi-cylinder engine E includes: a cylinder block 12, which is provided with a cylinder bore 11 inside; a cylinder head 14, which is joined with the top surface of the cylinder block 12; a cylinder head cover 16, which is connected to the cylinder head The top surface of 14 is joined, and in each cylinder bore 11 ..., piston 13 ... is slidably fitted, and the combustion chamber 15 ... facing the top of each piston 13 ... is formed between the cylinder block 12 and the cylinder head 14 .

[0055] On cylinder head 14, be provided with intake port 17 ... and exhaust port 18 ... that can communicate with each combustion chamber 15 ..., and each intake port 17 ... is respectively opened by a pair of intake valves 19 ... as engine valves. Each exhaust port 18 is opened and closed by a pair of exhaust valves 20... respectively...

Embodiment 2

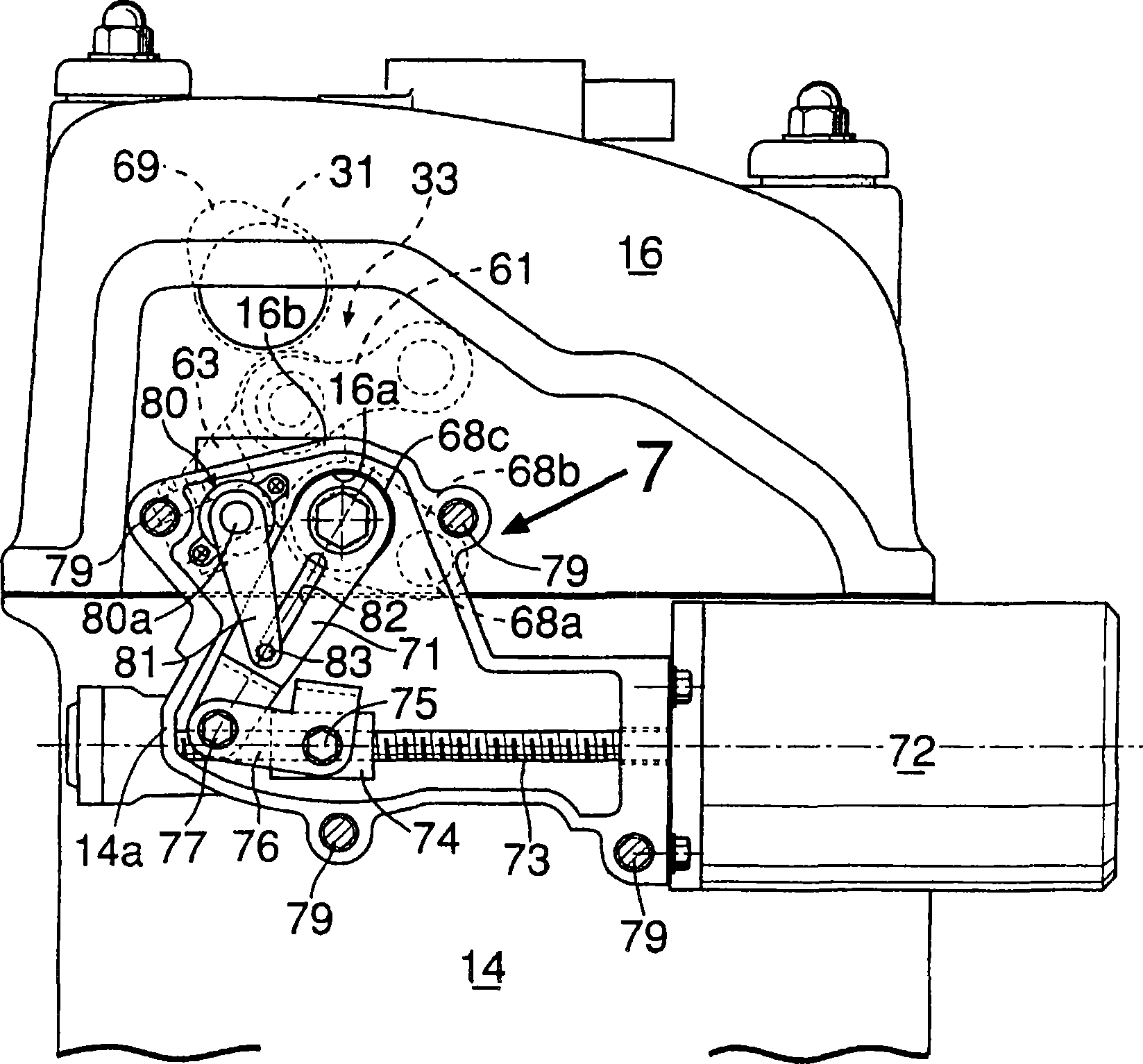

[0106] Figure 12 to Figure 19 The second embodiment of the present invention is shown, and the same reference numerals are assigned to the parts corresponding to the above-mentioned first embodiment.

[0107] First, in Figure 12 to Figure 14 Among them, on the cylinder head 14, upper support members 98..., 100... are fastened as support walls in a manner arranged on both sides of each cylinder, and end covers 99..., 100... are fastened to each upper support member 98... from above, The end caps 99 . . . , 100 . . . together form an intake-side cam support 101 . Furthermore, the intake camshaft 31 is rotatably supported between the upper support member 98... constituting the intake side cam support member 101 and the end cover 99, and the upper support member 98 constituting the exhaust side cam support member 102... ... and the end cover 100 ... is rotatably supported by an exhaust camshaft 103 .

[0108]The exhaust side rocker shaft 104 is supported by the upper support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com