Inner-expanded-type solar vacuum heat-collecting pipe

A technology of trough solar energy and vacuum heat collecting tubes, which is applied in the direction of solar heat collectors, solar heat collector safety, and solar thermal energy. It can solve problems such as complex processes, difficulty in high temperature tolerance, and limited length, and achieve simplified installation and connection. Structure, satisfying high-power heat collection and maintaining long-term sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

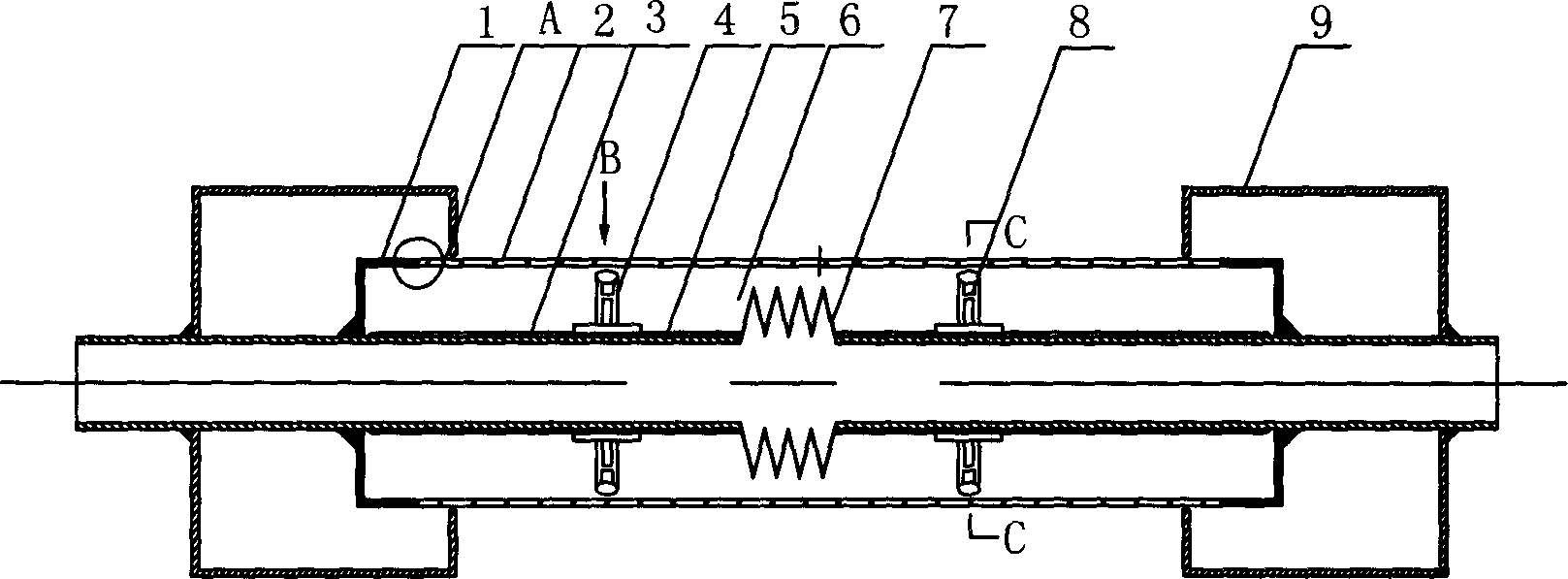

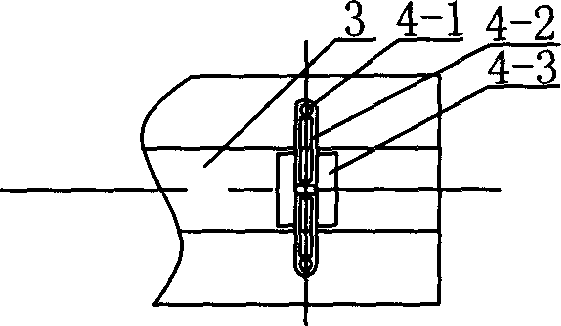

[0017] The internal expansion tank type solar vacuum heat collecting tube of the present embodiment is as figure 1 As shown, the structure is that the glass tube 2 is set on the central metal tube 3, and a getter is placed in the tube to achieve and maintain a vacuum degree of 10-2 Pa in the tube to form a vacuum layer 6. The surface of the metal pipe is coated with a solar light absorbing coating 5 . The metal pipe 3 is split in the middle, and a wave expansion joint 7 is added for sealing welding, so as to compensate the expansion difference between the glass pipe 2 and the metal pipe 3 after the temperature rises. Self-centering supports 4 and 8 are respectively installed in the middle of the two sections of metal pipe 3, and its specific structure is as follows image 3 and Figure 4 As shown, the self-centering support is composed of an arc support seat 4-3, an elastic support piece 4-2, and a contact head 4-1. The arc radius of the arc support seat 4-3 matches the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com