Airbag-device cover and airbag device

A technology for airbags and interior decorations, applied in applications, household components, household appliances, etc., which can solve problems such as flying, insufficient fixation, and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

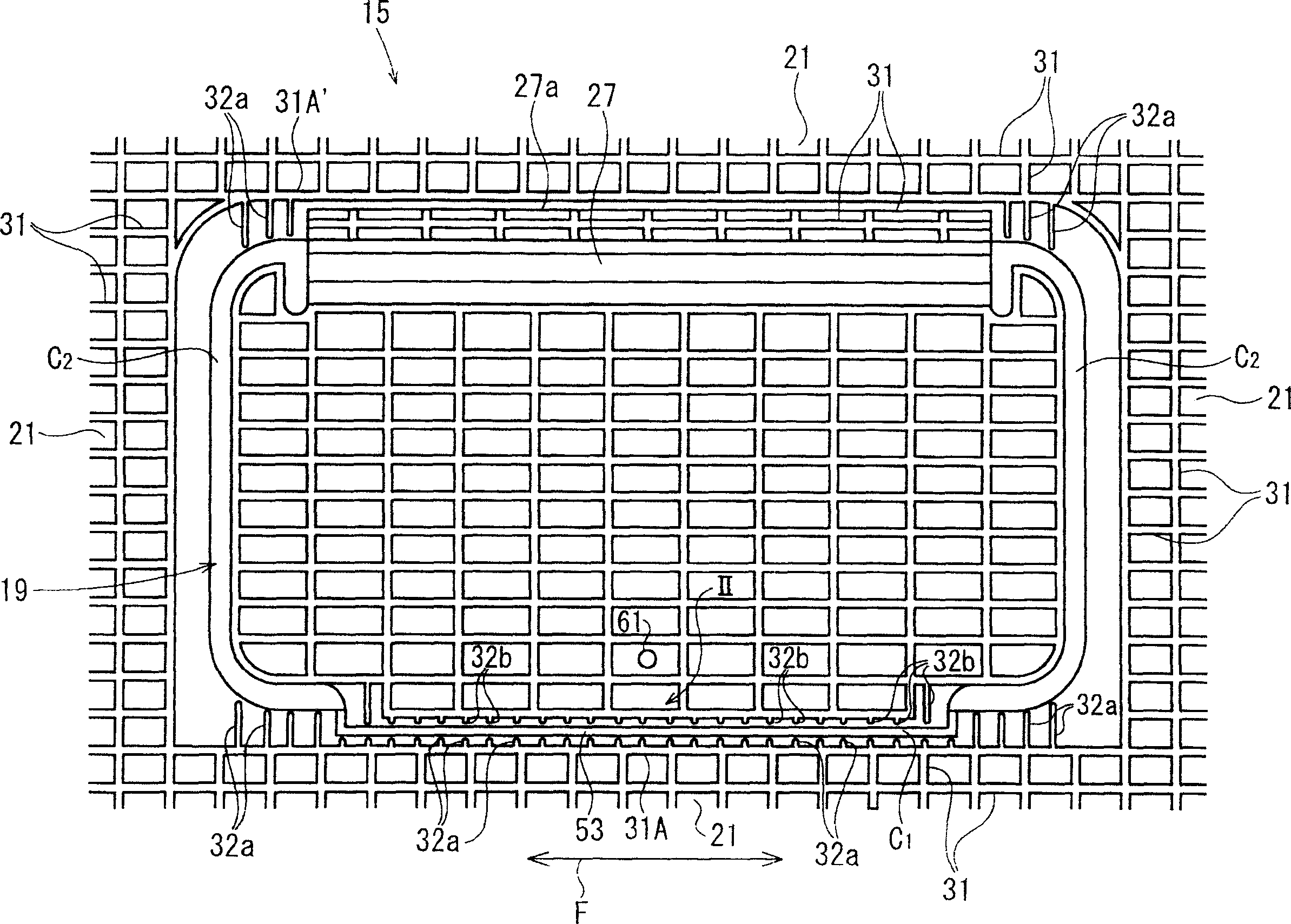

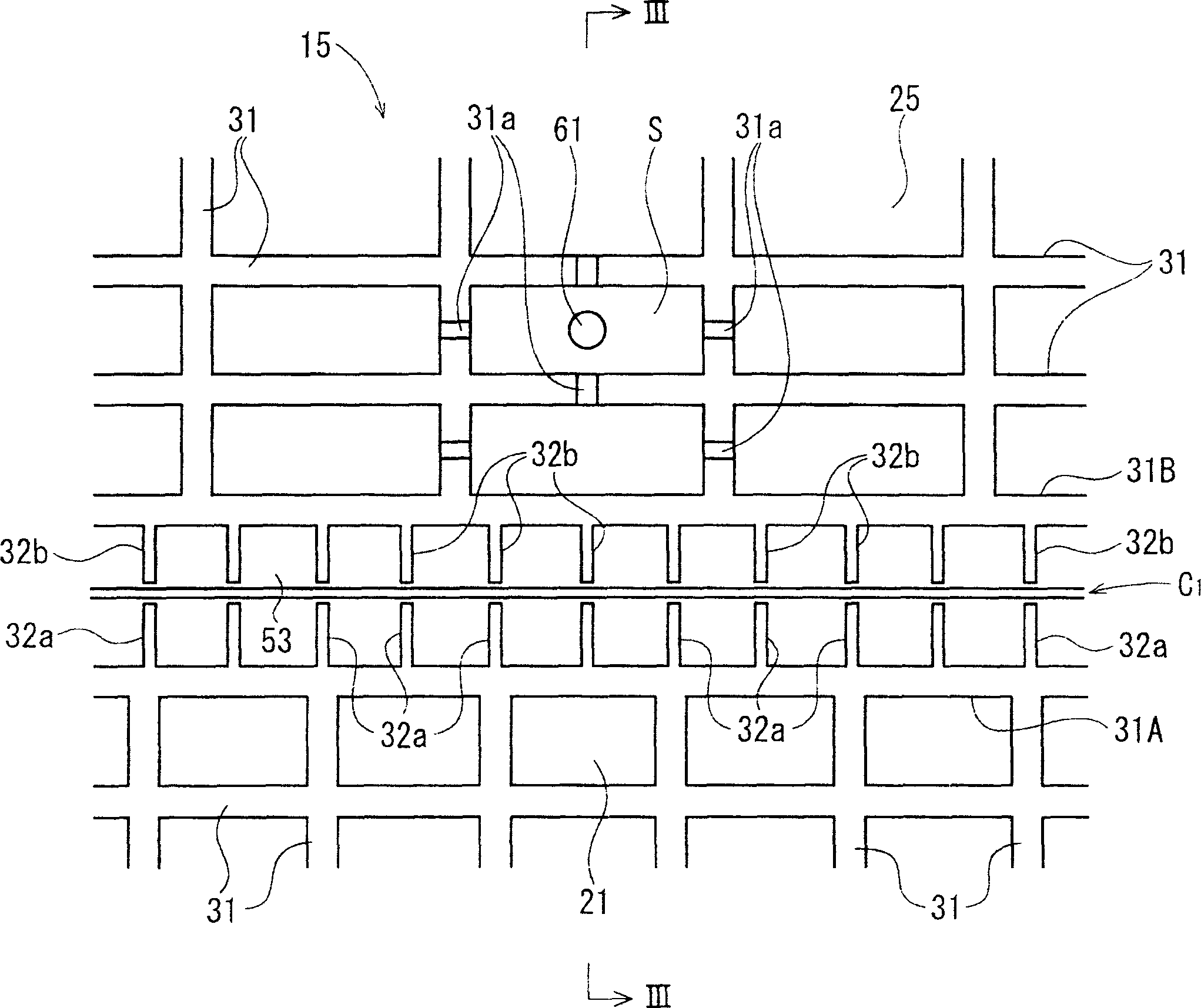

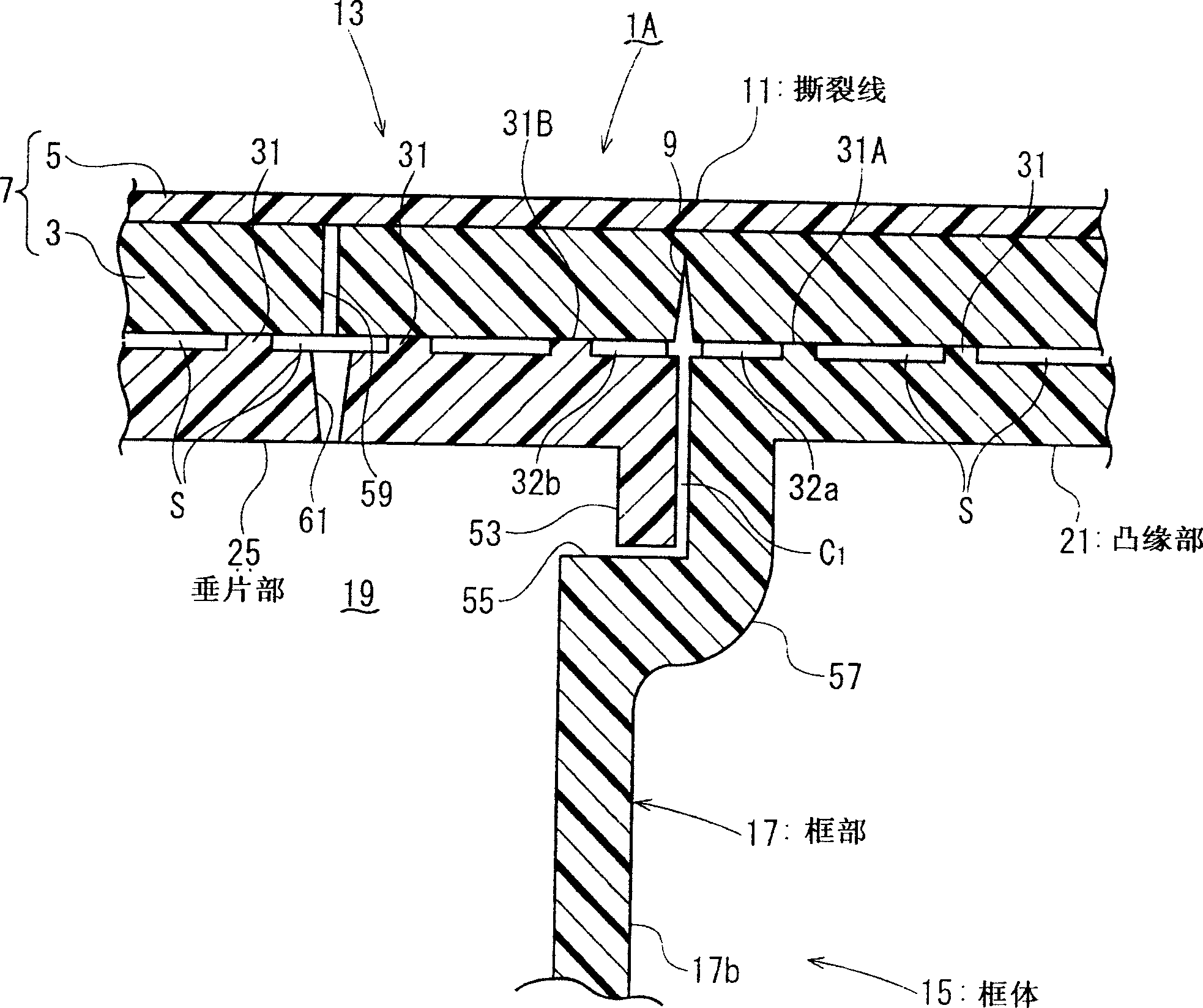

[0036] figure 1 It is a top view of the frame body and lining parts of the embodiment; figure 2 yes figure 1 Enlarged view of part II of ; image 3 is along figure 2 Sectional view of line III-III; Figure 4 It is an enlarged perspective view of a welded rib.

[0037] This embodiment is to apply the present invention to the above-mentioned Figure 5 to Figure 7 An example of a cover for an airbag device is shown.

[0038] In this embodiment, from among the welded ribs 31 extending in a grid pattern on the upper surfaces of the flange portion 21 and the tab portion 25, the one closest to the tear line 11 and along the amplitude direction during vibration welding The extended main ribs are welded ribs 31A (on the side of the flange portion 21 ) and 31B (on the side of the tab portion 25 ), and a plurality of branch ribs 32 a , 32 b are respectively extended tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com