Casting asphalt mixture vertical stirrer

An asphalt mixture and vertical mixer technology, which is used in roads, road repairs, roads, etc., can solve the problems of small mixing range of blades, limited mixing pot capacity, uneven mixing, etc., and achieve the expansion of axial mixing range, The effect of reducing resistance and stirring fully and evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

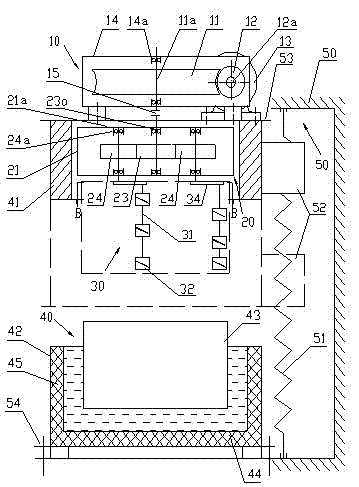

[0022] control figure 2 , mixer of the present invention mainly is made up of frame 50, motor 13, the first reduction mechanism 10, the second reduction mechanism 20, stirring shaft 31, stirring blade 32, lead screw rod 51, lead nut 52 and stirring pot 40. The motor 13 and the first reduction mechanism 10 are installed on the upper platform 53 . The first reduction mechanism 10 is a worm gear reduction mechanism, and the worm wheel 11 and the worm screw 12 are placed in the first reduction casing 14. The input shaft of the reduction mechanism is a worm shaft 12a, and the output shaft of the worm shaft and the motor 13 passes through a coupling ( not shown) connection. The worm 12 meshes with the worm wheel 11, and the worm gear shaft 11a is the output shaft of the first reduction mechanism, which is supported in the first reduction casing 14 by a pair of bearings 14a in the first reduction casing 14, and extends downwards through the first The outside of the reduction box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com