Lining half casing blank die forging forming method for recombination pressure container

A pressure vessel and forming method technology, which is applied in the field of composite pressure vessel lined semi-shell blank die forging, can solve the problems of difficulty in starting and high cost, and achieve the effects of saving mold costs, preventing wrinkles, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

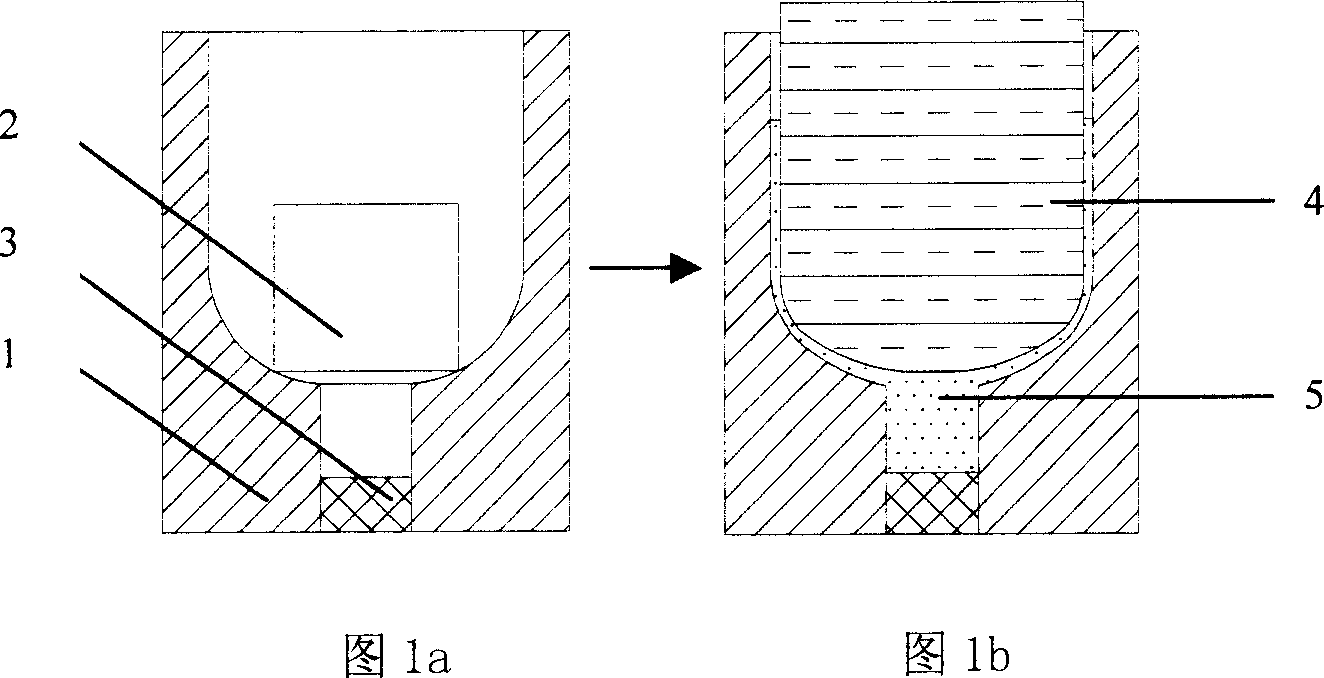

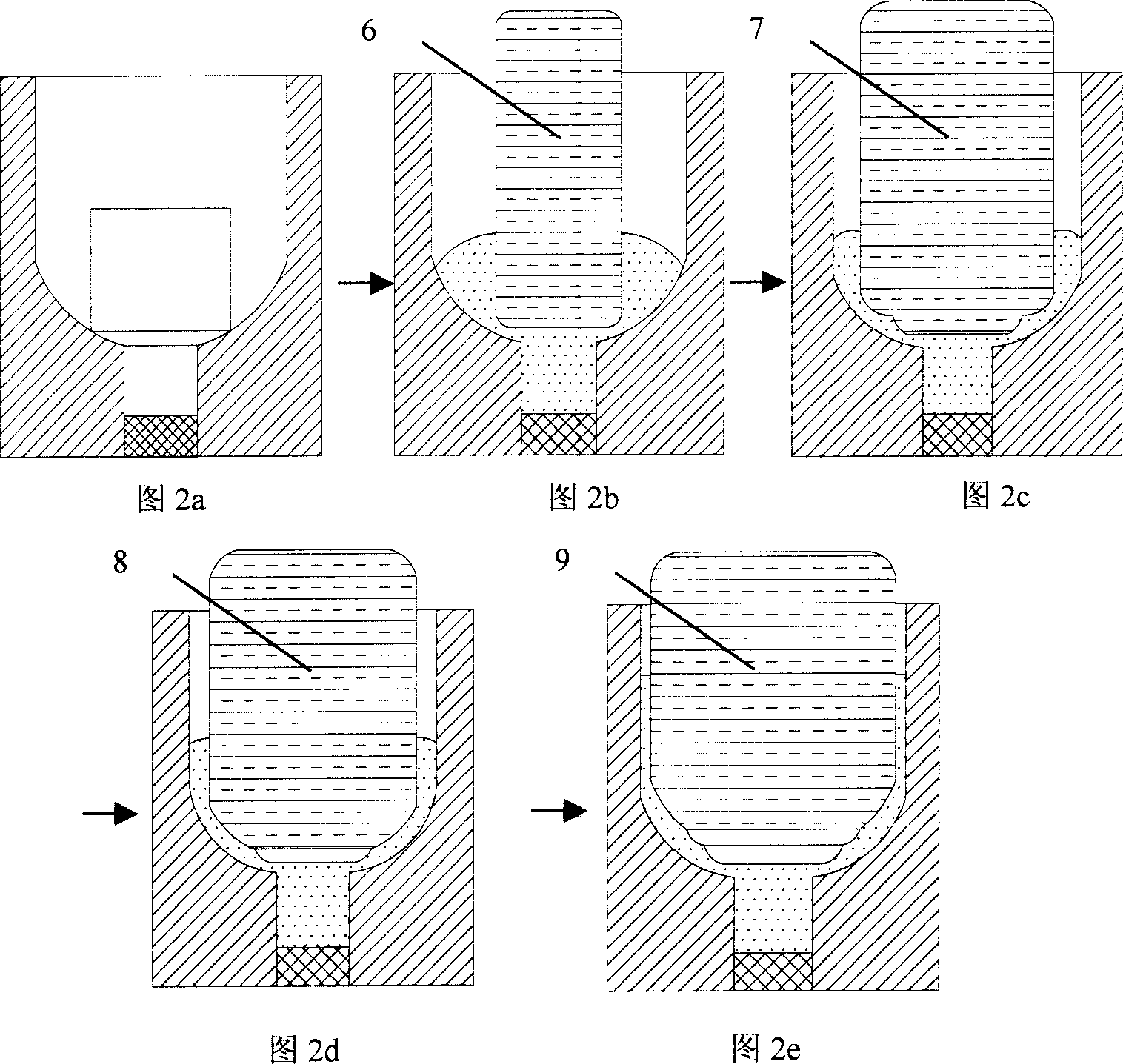

[0022] As shown in Figures 2a-e, a method for forging a composite pressure vessel lining half-shell blank according to the present invention includes:

[0023] 1. A die and at least two punches with different shapes and diameters. The diameter of the die in this example is 467 mm, the depth is 550 mm, the number of punches is 4, and the punch pressure in this embodiment is 900 tons;

[0024] 2. First install the female die and a punch 6 on the press, apply lubricant, preheat to a certain temperature, then take out the metal blank (aluminum in this embodiment) heated to the forming temperature from the heating furnace, put Put it into the female mold and align it. In this embodiment, oily graphite is used as the lubricant, and the preheating temperature of the die and a punch is about 250°C;

[0025] 3. Press a punch into the billet, then lift it up, take out the billet and return it to the furnace for heat preservation, and complete the first deformation. The diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com