Rotary yarn feeding device having passage-of-reeling-thread control guide, and sample warping machine

A channel control, warping machine technology, applied in warping machines, manufacturing tools, textiles and papermaking, etc., can solve the problems of loose yarn, yarn breakage, looseness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, an embodiment of the present invention will be described with reference to the drawings. The embodiments shown in the drawings are for illustrative purposes only, and the present invention can be modified in various ways without departing from its protection scope and technical concept except for the illustrated embodiments.

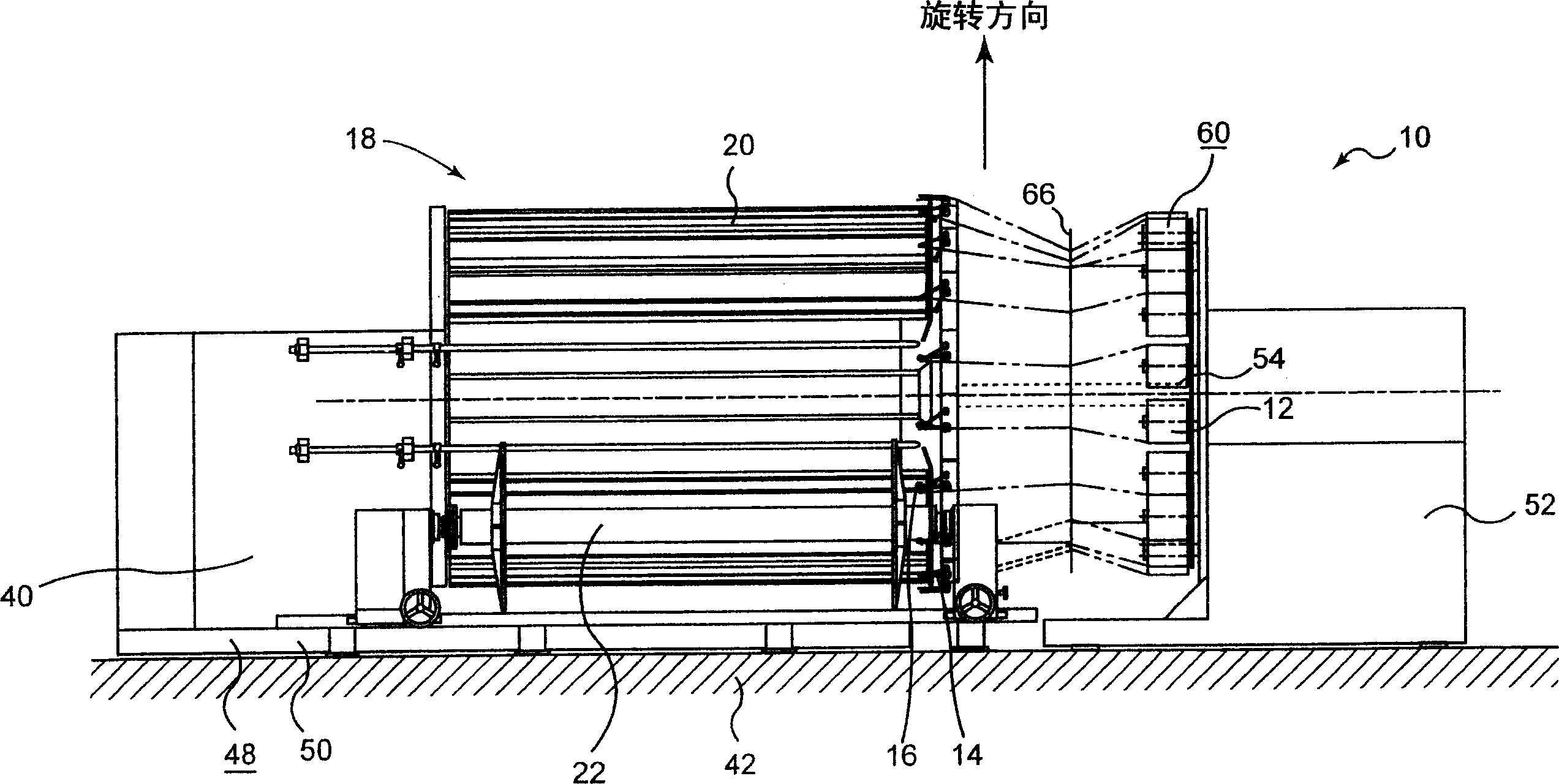

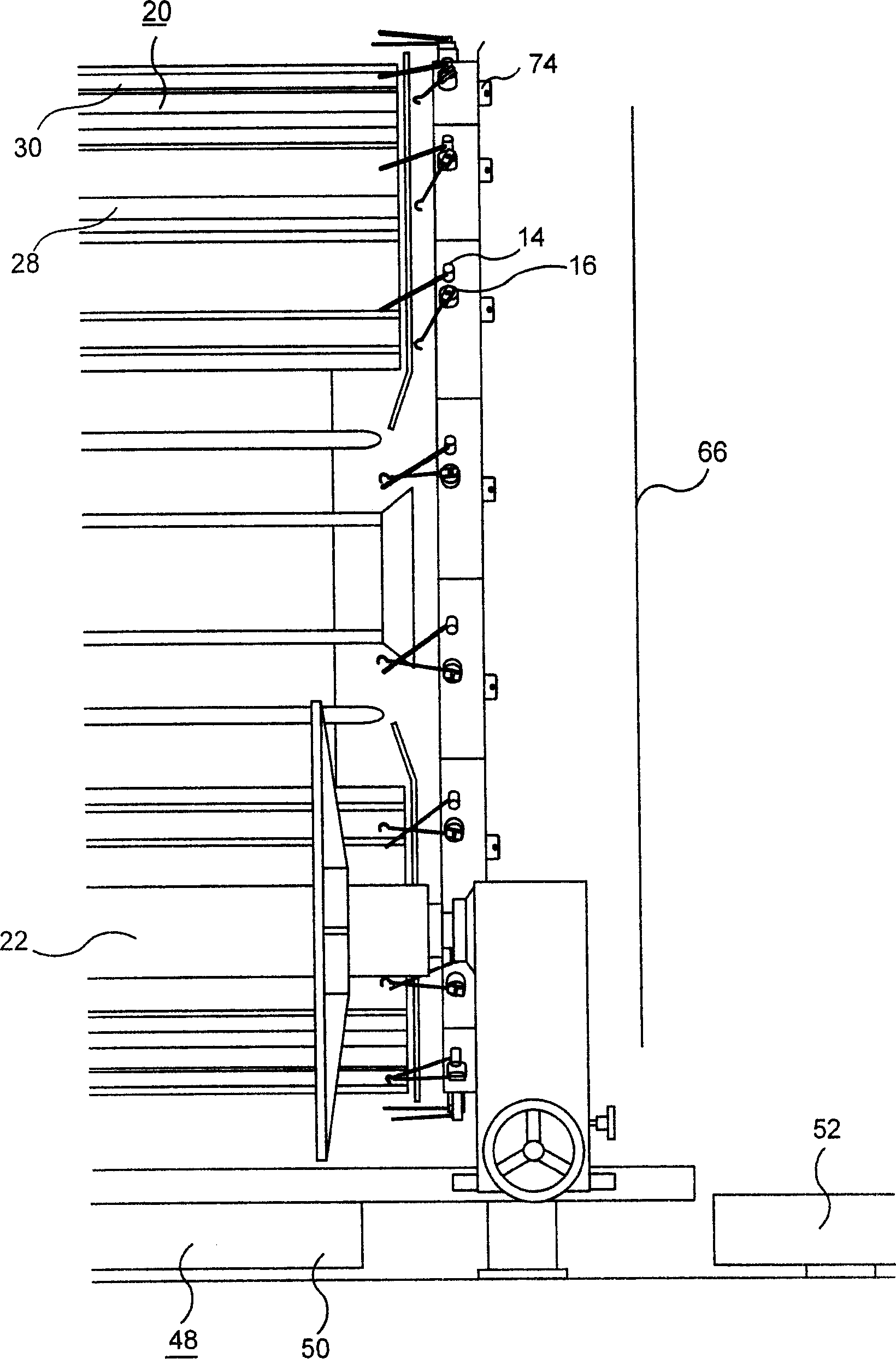

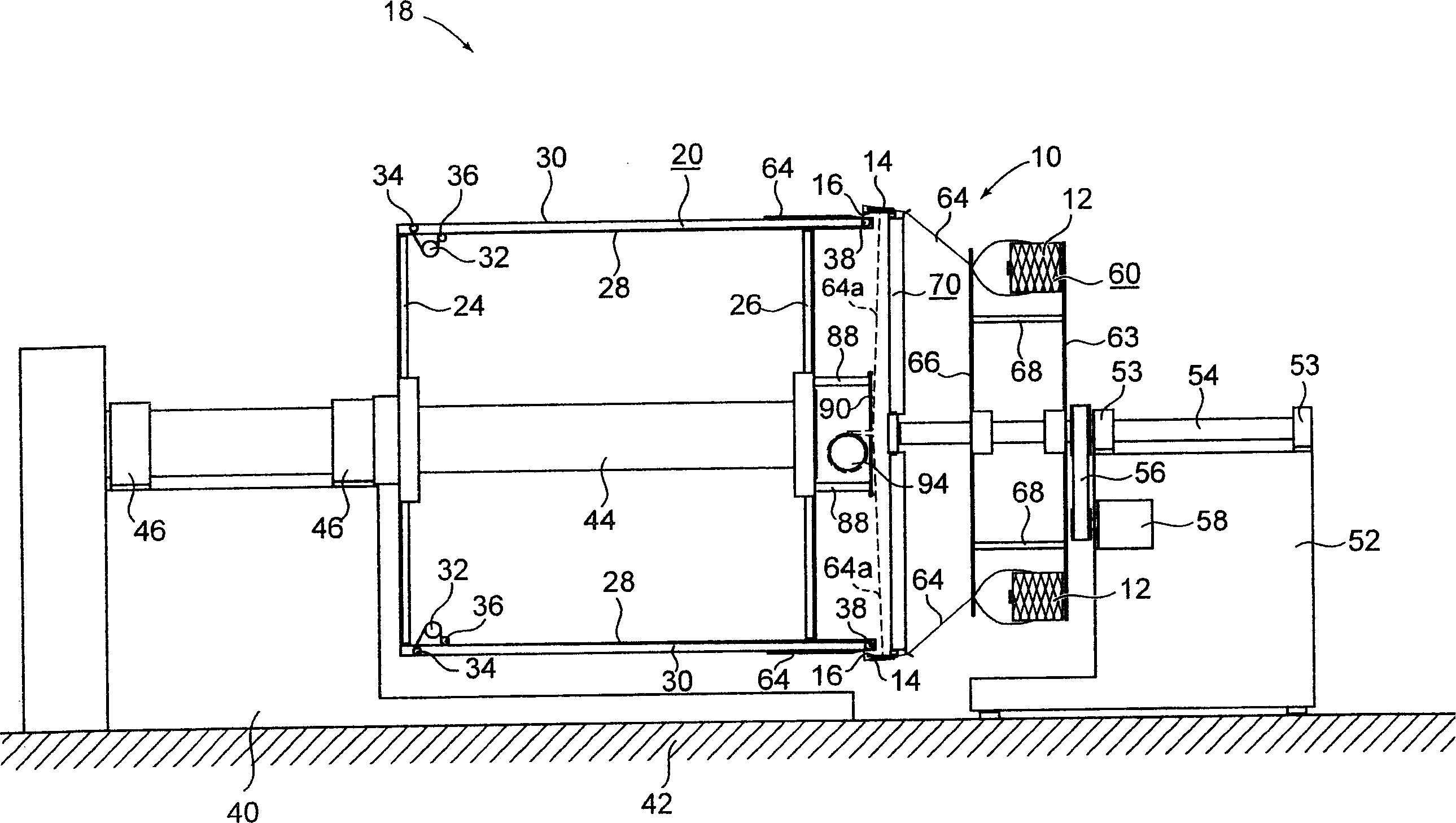

[0030] exist figure 1In, reference numeral 10 denotes a rotary yarn supplying machine having a yarn passage control yarn guide of the present invention. A rotary yarn feeding machine 10 with yarn passage control yarn guides comprises a plurality of bobbins 12 on which yarns of the same type and / or different types are wound; a plurality of yarn guides 14 for for winding the yarn unwound from the bobbin 12 on the warper cylinder; and the movable yarn path control yarn guide 16, which is arranged in the vicinity of the yarn guide 14, can be shifted so as to control After unwinding from the bobbin 12, the yarn passes through the yarn guide 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com