Catalyst for preparing hexafloroacetone by isomerization method and its preparing method and use

A technology of hexafluoroacetone and catalyst, which is applied in the field of catalyst for preparing hexafluoroacetone by isomerization method and its preparation and application field, and can solve the problems of high requirements on reaction conditions, low conversion rate of raw materials, low selectivity of hexafluoroacetone, etc. problems, to achieve the effects of improved thermal conductivity and heat resistance stability, simple preparation process, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

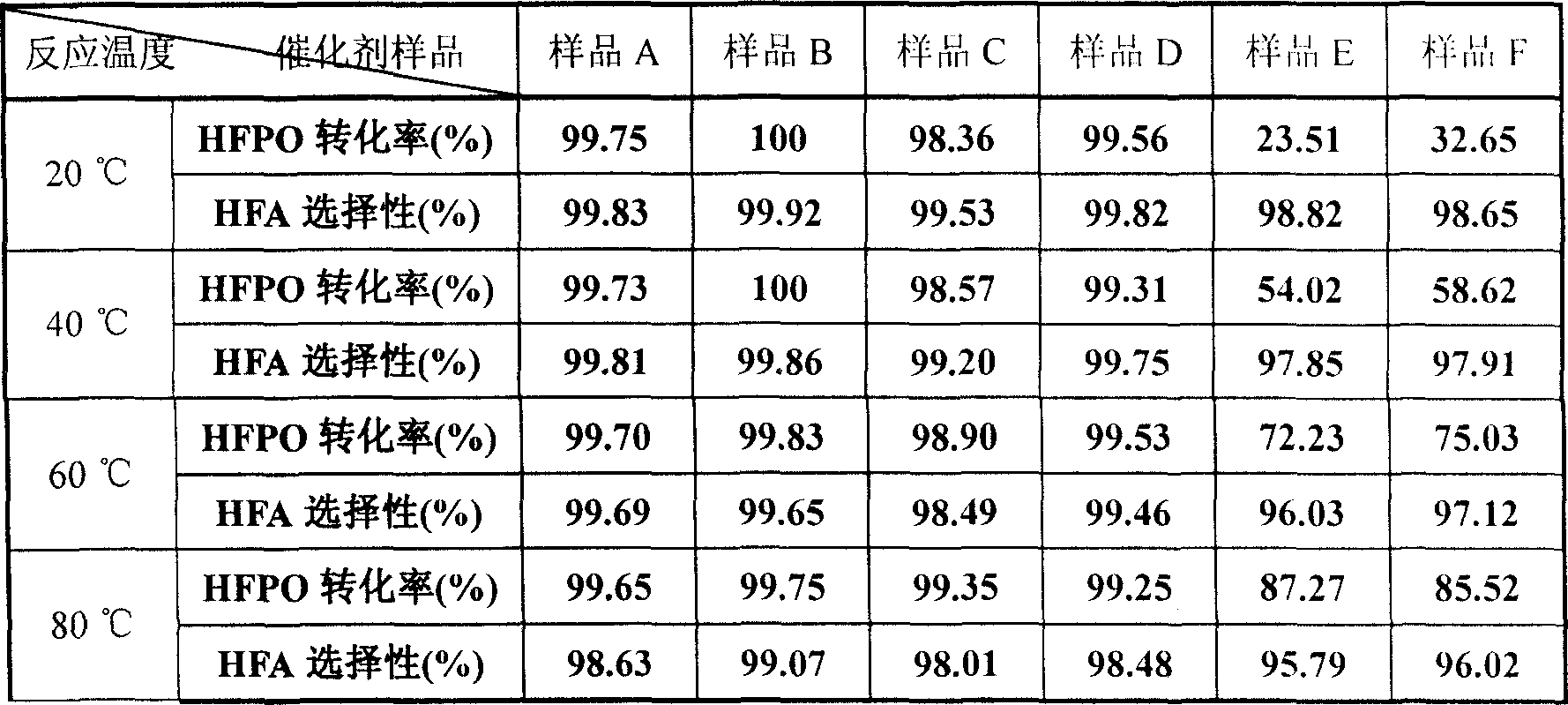

Examples

Embodiment 1

[0035] Example 1: Cr 2 o 3 -AlF 3 -TiO 2 -Graphite Composite Lewis Acid Catalyst (Sample A)

[0036] Weigh 1.40g Cr(OH) 3 , 6.75g AlF 3 , 29.24g TiO 2 , 4.18g of aluminum powder, mixed mechanically, added 40ml of deionized water to mix well, placed in the air atmosphere overnight, dried in a constant temperature drying oven at 120°C for 5.0h, took out, crushed and screened out 20-40 mesh samples, and put them in with an inner diameter of 7.3 mm quartz reaction tube, programmed to heat up to 350°C for 5.0h under nitrogen, with a heating rate of 1°C / min, N 2 Airspeed 600h -1 . After the activation is completed, put it into the desiccator for later use.

Embodiment 2

[0037] Example 2: Cr 2 o 3 -AlF 3 -TiO 2 - Aluminum powder composite Lewis acid catalyst (sample B)

[0038] According to the method of embodiment 1, take by weighing 1.40g Cr(OH) 3 , 6.75g AlF 3 , 29.24g TiO 2 , 4.18g of aluminum powder, mixed mechanically, added 45ml of deionized water, dried, and activated by temperature programming to make sample B and put it in a desiccator for later use.

Embodiment 3

[0039] Example 3: Cr 2 o 3 -TiO 2 - Graphite Composite Lewis Acid Catalyst (Sample C)

[0040] As the method of embodiment 1, take by weighing 10.38g Cr(OH) 3 , 27.0g TiO 2 , 4.15g of graphite, mixed mechanically, added 35ml of deionized water, dried, and activated by temperature programming to make sample C and put it in a desiccator for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com