Method for purifying exhaust gas by micronizing washing liquid and matching disturbance flow

A cleaning solution and micronization technology, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of long downtime and other problems, and achieve the effects of increasing residence time, easy hardware maintenance, and saving operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

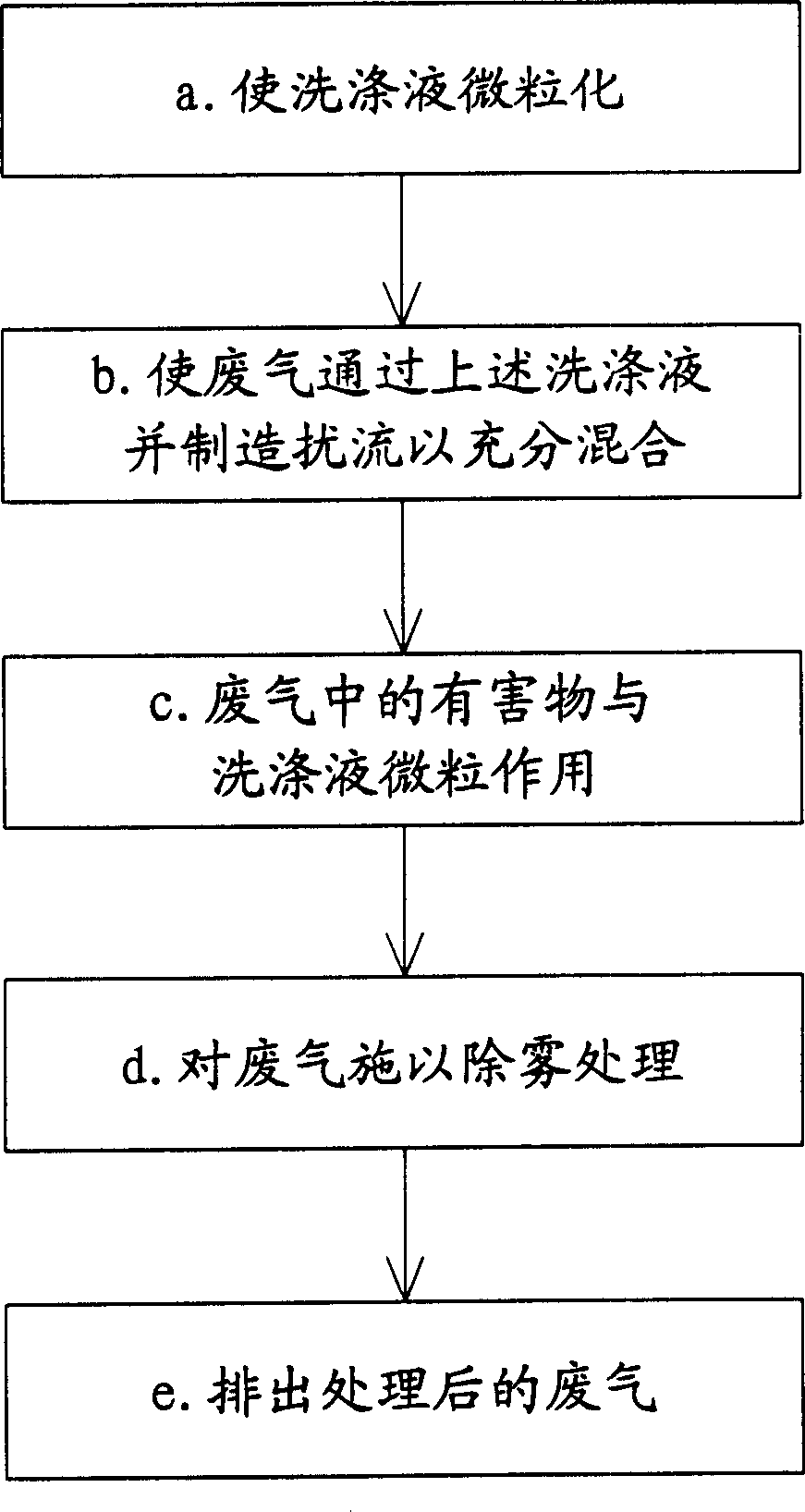

[0041] like figure 1 Shown, the steps of the present invention are as follows:

[0042] a. Micronize the washing liquid;

[0043] b. Let the exhaust gas pass through the above washing liquid and create a turbulent flow to fully mix;

[0044] c. The harmful substances in the exhaust gas interact with the particles of the washing liquid;

[0045] d. Apply demisting treatment to exhaust gas;

[0046] e. Discharge the treated waste gas.

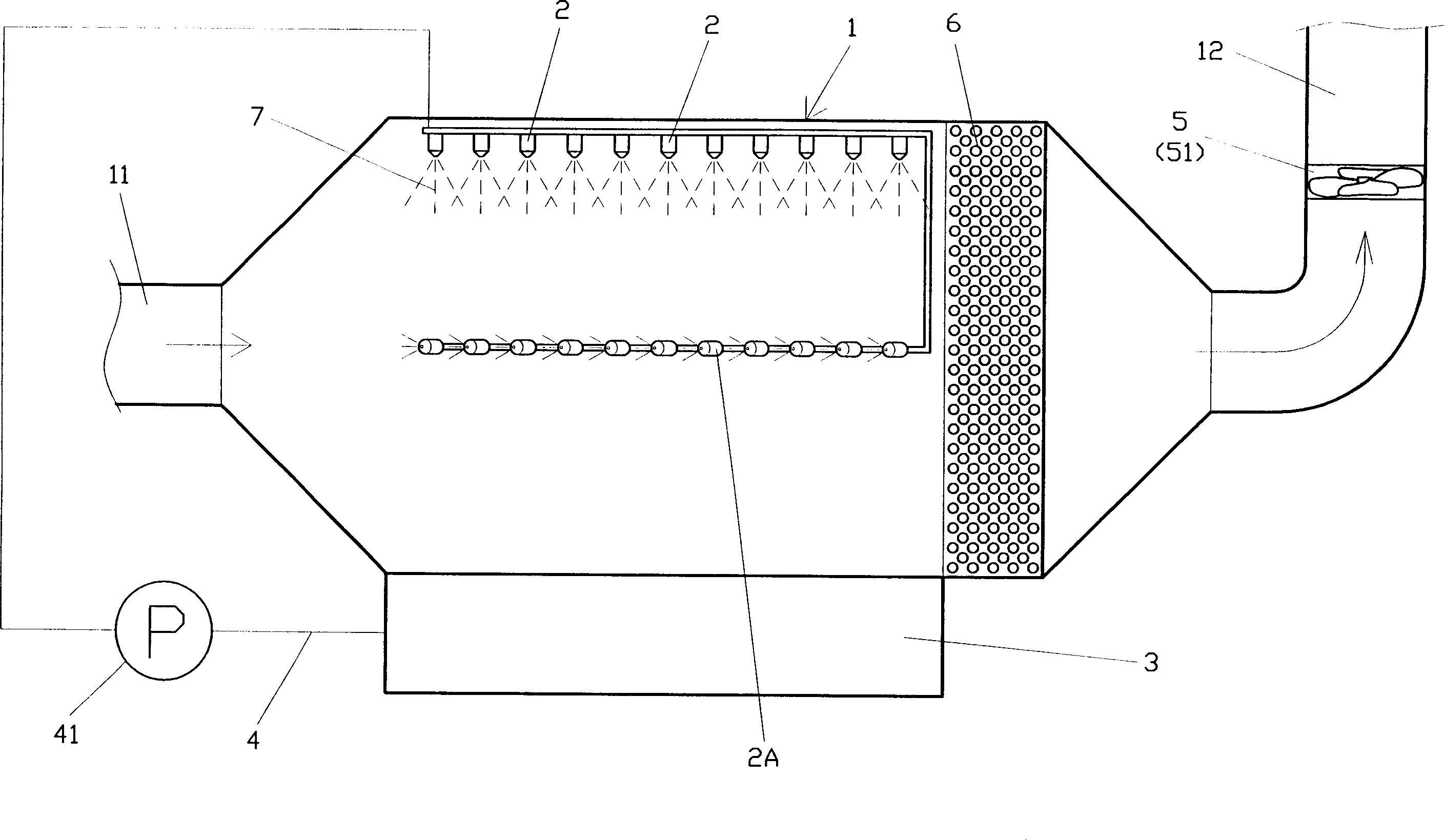

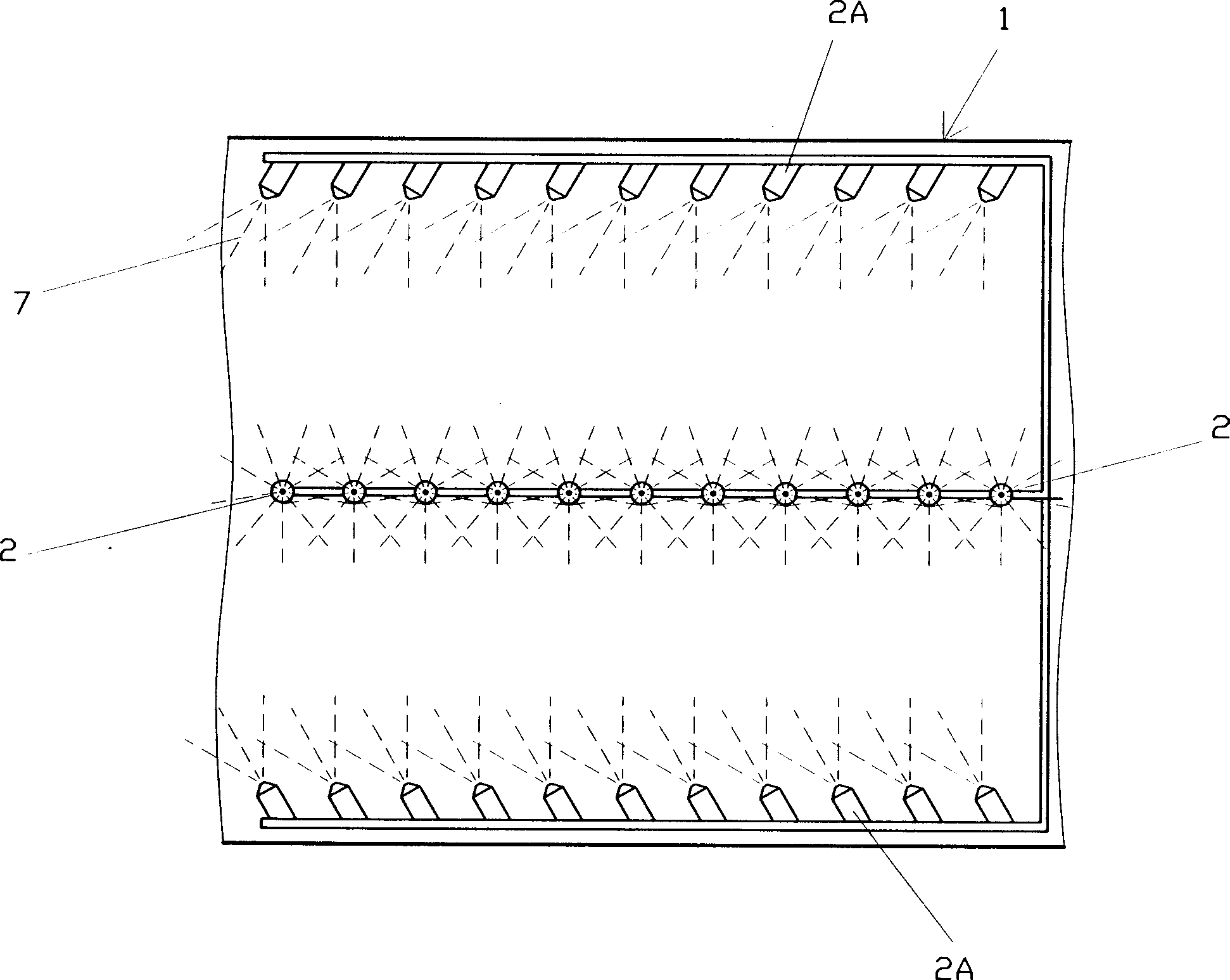

[0047] please cooperate figure 2 , When implementing the present invention, the scrubber 1 used includes an atomizer 22A, a collecting tank 3, a return pipeline 4, a negative pressure generating unit 5, and a demisting layer 6, etc. During operation, the exhaust gas is sent in from the inlet 11 of the scrubber 1, and the cleaning solution 7 is atomized into particles of 10 μm-1000 μm through the atomizer 22A, and the atomized cleaning solution 7 is fully mixed with the above-mentioned exhaust gas to make the exhaust gas The harmful substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com