Flat plate heat transfer device and method for manufacturing the same

A flat-panel, heat source technology, used in cooling/ventilation/heating transformation, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as not easy, easy to break or deform, and reduce product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

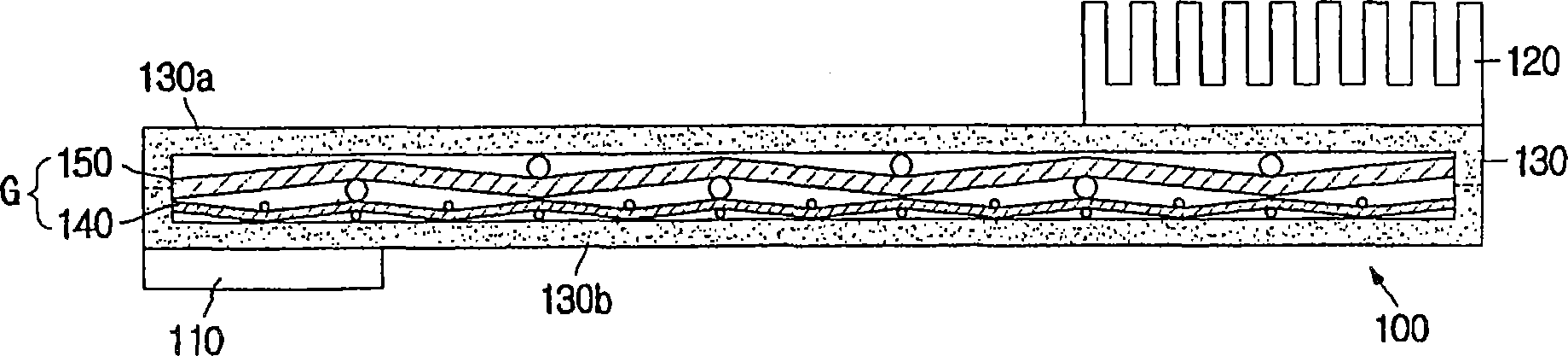

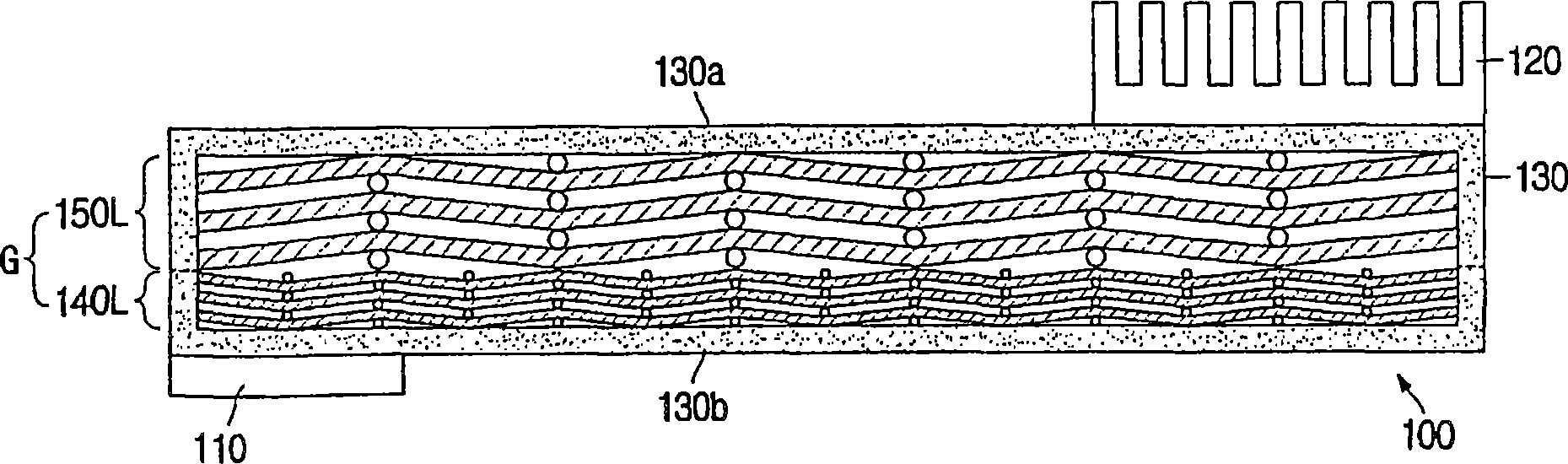

[0103] The inventors used electrolytic copper foil with a thickness of 0.1mm to prepare Figure 15 The upper and lower plates of the flat container shown in the flat container, and then install the network polymer in the flat container (it is constructed, such as Figure 17 A coarse mesh is inserted between two fine meshes as shown in ) to make three types of flat plate heat transfer devices as shown in Table 1 below.

[0104] Coarse mesh

fine mesh

Type 1 (sample 1)

main direction

second to

Type 2 (sample 2)

main direction

main direction

Type 3 (Example 3)

second to

main direction

[0105] The width, length and height of samples 1, 2 and 3 were 120mm, 50mm and 1.3mm respectively, and the mesh used was a copper mesh with a copper content of at least 99%. The wire diameter d of the coarse mesh is 0.225mm, the mesh thickness is 0.41mm and the mesh number is 15, while the mesh wire diameter d of the fine mesh is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com