Glass fiber reinforced plastic pipeline and its production process

A glass fiber and reinforced plastic technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of high friction resistance, rising price of glass fiber reinforced plastic pipes, and uneven cement surface, and achieve good comprehensive performance and designability of products. Strong, good appearance quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that this example is not intended to limit the present invention. Where glass fiber reinforced plastic pipes are prepared using a process similar to the present invention in pultrusion-winding-injection composite molding, All should be included in the protection scope of the present invention.

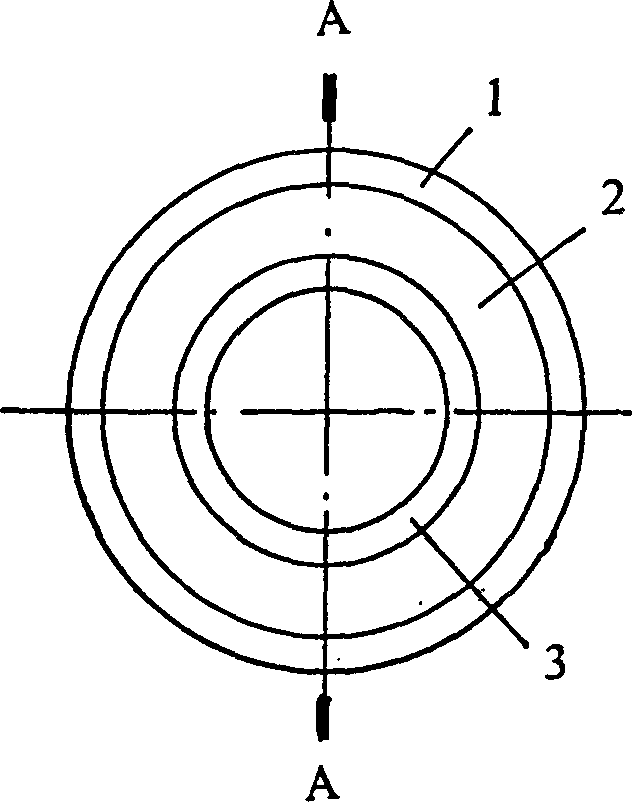

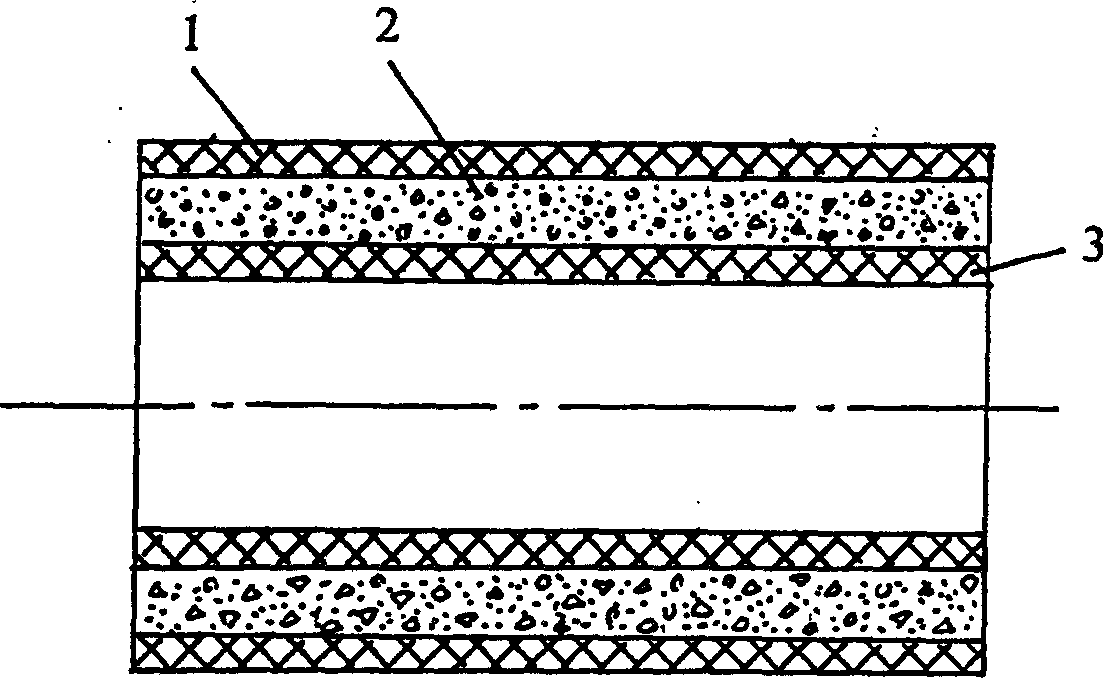

[0017] A glass fiber reinforced plastic pipe, comprising an outer structural layer (1) and an inner structural layer (3), characterized in that a filler layer (2) is placed between the outer structural layer (1) and the inner structural layer (3) .

[0018] The technological process for producing the above-mentioned glass fiber reinforced plastic pipes is as follows:

[0019] ① The production mold adopts inner mold and outer mold;

[0020] ②The glass fiber is impregnated with unsaturated polyester resin and wound on the outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com