Detachable feed trays with self adjusting side guides

A side guide plate, adjustable technology, applied in the direction of thin material handling, object separation, positioning objects, etc., can solve the problems of inability to convey materials, inability to properly guide materials, etc., and achieve the effects of accelerating loading speed, increasing output, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

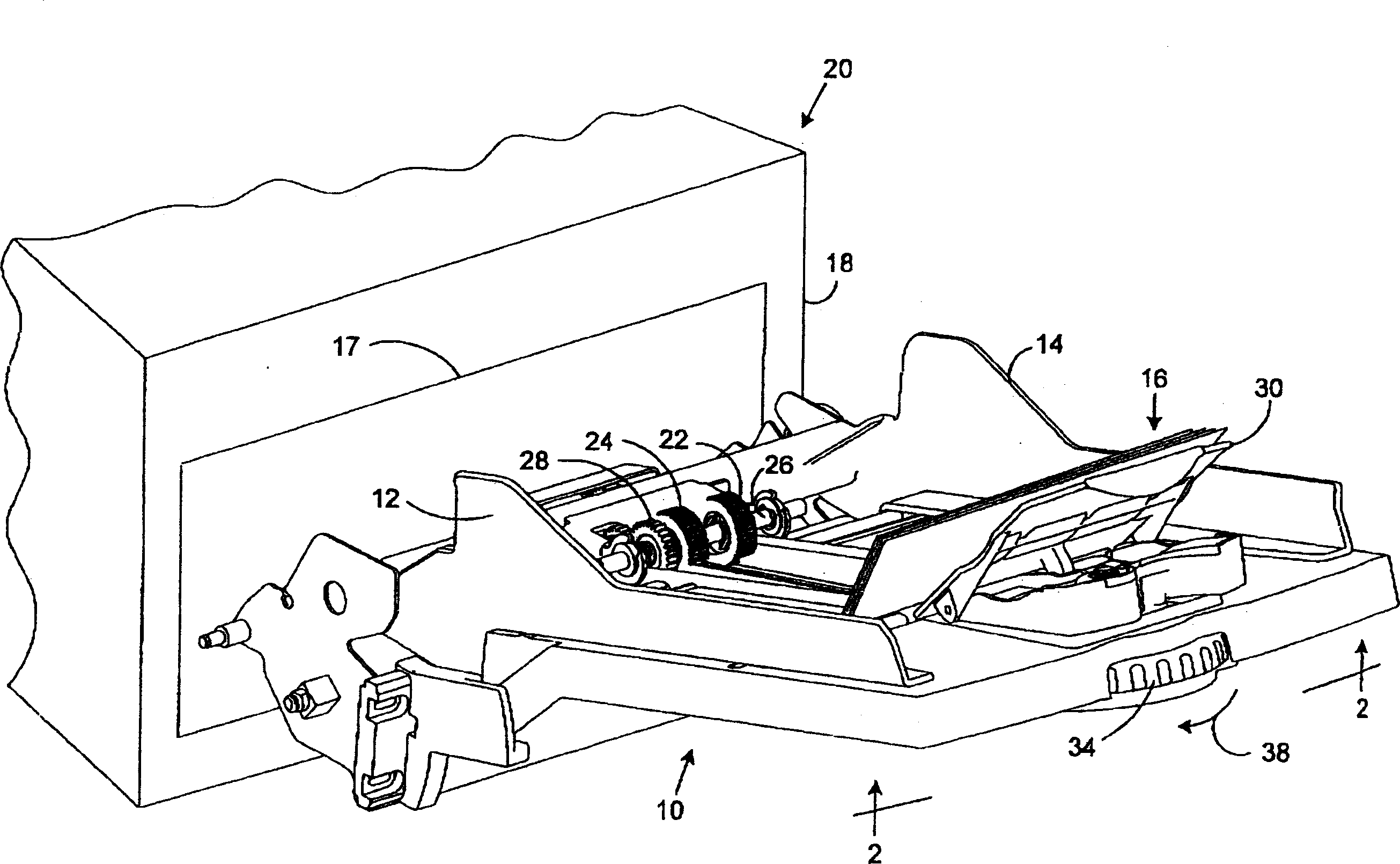

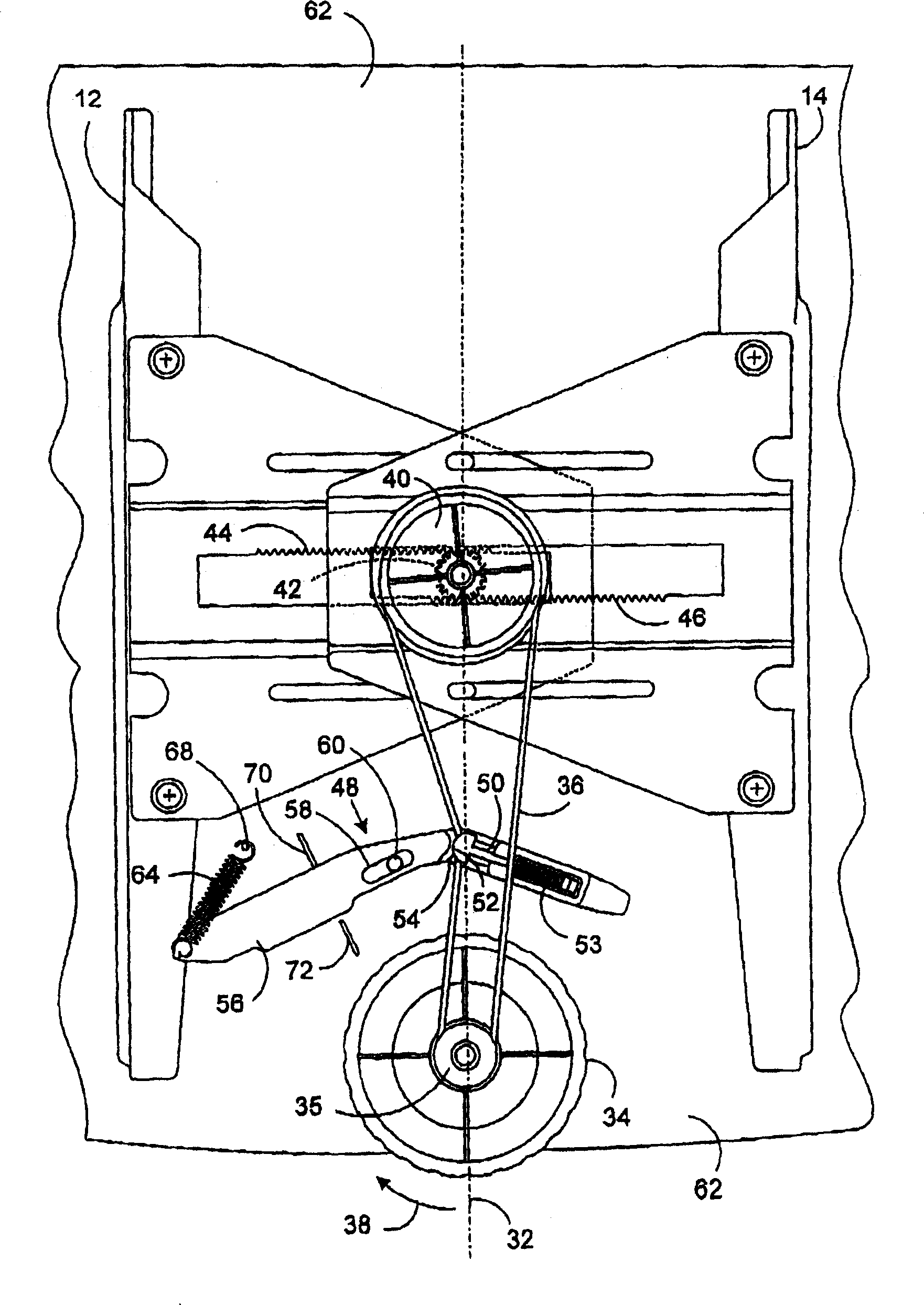

[0016] Reference will now be made to the accompanying drawings and in particular to the figure 1 . The removable feed tray 10 has side guides 12 and 14 . The feeding tray 10 is detachably connected to the separating and feeding mechanism 18 of the paper processing device 20 . Side guides 12 and 14 constrain and guide material, such as envelopes 16 , loaded in a shingled arrangement into separation and feeding mechanism 18 when feed tray 10 is coupled to apparatus 20 . Apparatus 20 may be any type of apparatus required to convey material suitable for placement in a feeder tray. Examples of such equipment are insertion systems, folding systems, printing machines, copiers, and the like. The separation and feeding mechanism 18 can be of standard design, such as that used in the Pitney Bowes tabletop inserter, model F-350 tabletop inserter, both types of inserters are sold by Pitney Bowes Inc. of Stamford, Connecticut, USA .

[0017] When feed tray 10 is attached to device 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com